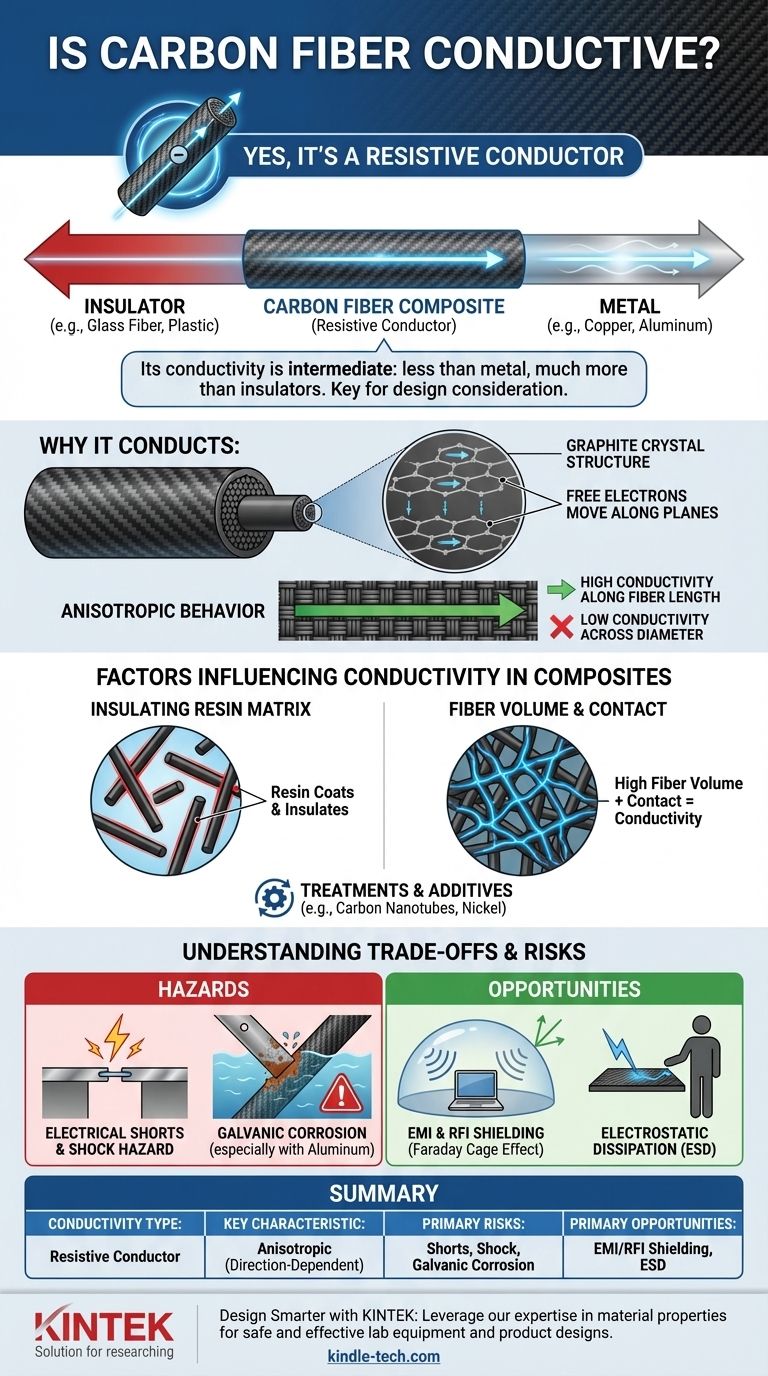

Yes, carbon fiber is electrically conductive. However, its level of conductivity is fundamentally different from that of metals like copper. This property is not a simple "on or off" switch; it varies based on the specific type of fiber and how it's used in a composite part, making it a critical design consideration.

The central takeaway is that carbon fiber should be treated as a resistive conductor. Its unique ability to conduct electricity—though not as efficiently as metal—creates significant opportunities for applications like electronic shielding, but also introduces critical risks like short circuits and galvanic corrosion if not properly managed.

What Makes Carbon Fiber Conductive?

The electrical properties of carbon fiber are a direct result of its atomic structure. Understanding this is key to using it effectively.

The Graphite Crystal Structure

Carbon fibers are composed of tightly packed, crystalline carbon atoms. This structure is similar to graphite, where electrons are able to move freely along the planes of carbon atoms.

This movement of electrons is, by definition, an electrical current. Therefore, the inherent structure of the individual carbon filaments is what makes them conductive.

Conductivity Compared to Metals

It is crucial to set a proper baseline. Carbon fiber is a conductor, but it is not a high-performance one like metal wire.

Its conductivity is many times greater than insulators like glass fiber or plastics. However, it is significantly less conductive (i.e., more resistive) than copper or aluminum. This intermediate status is what defines its unique applications and challenges.

Anisotropic Behavior

A critical concept is that carbon fiber's properties are anisotropic, meaning they are direction-dependent.

A carbon fiber composite is highly conductive along the length of the fibers but is significantly less conductive across their diameter. The overall conductivity of a final part depends on how these fibers are layered and oriented.

Factors Influencing Conductivity in Composites

Raw carbon fiber is almost never used alone. It is typically combined with a polymer resin (like epoxy) to form a rigid composite part. This combination dramatically affects the final electrical performance.

The Insulating Resin Matrix

The resin matrix that holds the fibers together is a strong electrical insulator. This resin coats the fibers, and the bulk conductivity of the final part depends on the fibers being close enough to create a continuous electrical path.

Fiber Volume and Contact

For a composite part to conduct electricity effectively, there must be a high fiber volume fraction. More importantly, the individual fibers must touch each other.

If the fibers are sparse and fully encapsulated by resin, the part may be largely non-conductive. If they are densely packed, an effective conductive network is formed.

Treatments and Additives

As the reference material notes, carbon fiber or the resin it's mixed with can be treated to enhance conductivity. This is often done by adding other conductive materials, like carbon nanotubes or nickel coatings, to the composite.

Understanding the Trade-offs and Risks

Carbon fiber's conductivity is a double-edged sword that must be respected in any design.

Hazard: Electrical Shorts and Shock

Treating a carbon fiber part as a simple piece of plastic is a dangerous mistake. Because it conducts electricity, it can easily cause a short circuit if it bridges two electrical contacts.

Furthermore, it presents a significant shock hazard if it comes into contact with a high-voltage source, as the current can travel through the material.

Hazard: Galvanic Corrosion

When carbon fiber is placed in direct contact with most metals in the presence of an electrolyte (like salt water), it creates a galvanic cell. Carbon fiber is highly noble, meaning it will cause the less noble metal—especially aluminum—to corrode at an accelerated rate.

This is a major concern in the aerospace, marine, and automotive industries, where a barrier material (like a layer of fiberglass) is required to separate carbon fiber from metallic structures.

Opportunity: EMI and RFI Shielding

The conductive nature of carbon fiber makes it an excellent material for creating enclosures that shield sensitive electronics from electromagnetic interference (EMI) and radio-frequency interference (RFI). The conductive fiber network acts as a Faraday cage, blocking unwanted signals.

Opportunity: Electrostatic Dissipation (ESD)

In environments where static electricity buildup can damage sensitive components or create an explosion risk, carbon fiber composites provide a safe path for the static charge to dissipate before it can arc.

Making the Right Choice for Your Application

How you approach carbon fiber's conductivity depends entirely on your end goal.

- If your primary focus is safety around electrical systems: You must treat carbon fiber as an uninsulated wire. Ensure proper clearance and insulation to prevent short circuits and shock hazards.

- If your primary focus is protecting electronics (EMI/ESD): Leverage carbon fiber's conductivity by designing parts with high fiber volume and good fiber-to-fiber contact to ensure a continuous conductive path.

- If your primary focus is structural integrity with mixed materials: Always prevent direct contact between carbon fiber and metals like aluminum by using a non-conductive barrier layer to stop galvanic corrosion.

Ultimately, understanding carbon fiber not just as a strong material but as a resistive conductor is the key to unlocking its full potential while avoiding critical design flaws.

Summary Table:

| Property | Description |

|---|---|

| Conductivity Type | Resistive conductor (less conductive than metals like copper). |

| Key Characteristic | Anisotropic: conductive along the fiber length, less so across it. |

| Primary Risks | Electrical shorts, shock hazard, and galvanic corrosion with metals. |

| Primary Opportunities | EMI/RFI shielding and electrostatic dissipation (ESD). |

Designing with Conductive Composites? Let KINTEK Be Your Guide.

Navigating the electrical properties of materials like carbon fiber is critical for the safety and performance of your laboratory equipment or product. KINTEK specializes in providing high-quality lab equipment and consumables, helping you leverage material properties effectively while mitigating risks.

Whether you're developing new applications requiring EMI shielding or need to prevent galvanic corrosion in your designs, our expertise ensures you have the right tools and materials for success.

Contact our experts today to discuss your specific needs and discover how KINTEK's solutions can enhance your project's reliability and performance.

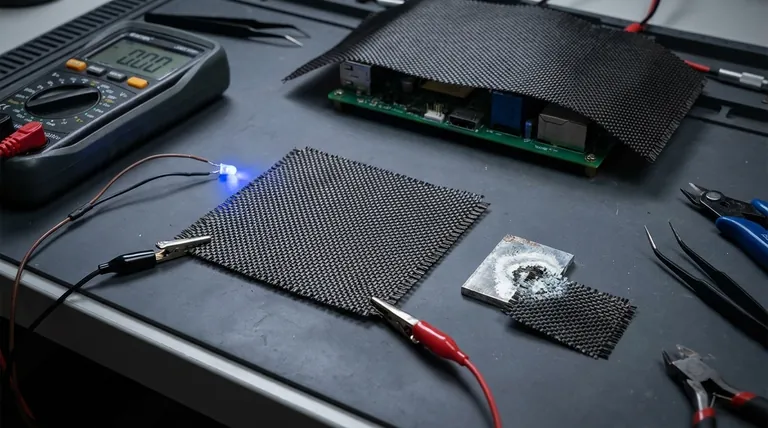

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Graphite Vacuum Continuous Graphitization Furnace

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What is the cost of biomass production? Unpacking the True 'Delivered Cost' to Your Facility

- How do you increase filter press efficiency? Optimize Your Dewatering System for Maximum Output

- What materials are sintered steel? Unlock the Secrets of Powder-Based Steel Manufacturing

- What is the cavity made in a suitable refractory materials that can withstand the high temperature into which molten metal can be? A Guide to Casting Molds

- How to calculate coating thickness? Select the Right Method for Accurate Results

- What is thin film industry? The Foundation of Modern Electronics, Optics, and Energy

- What is the thermal conductivity coefficient of graphite? A Guide to Its Anisotropic Properties

- What is the process of electron beam physical vapor deposition? Achieve High-Purity, High-Melting-Point Coatings