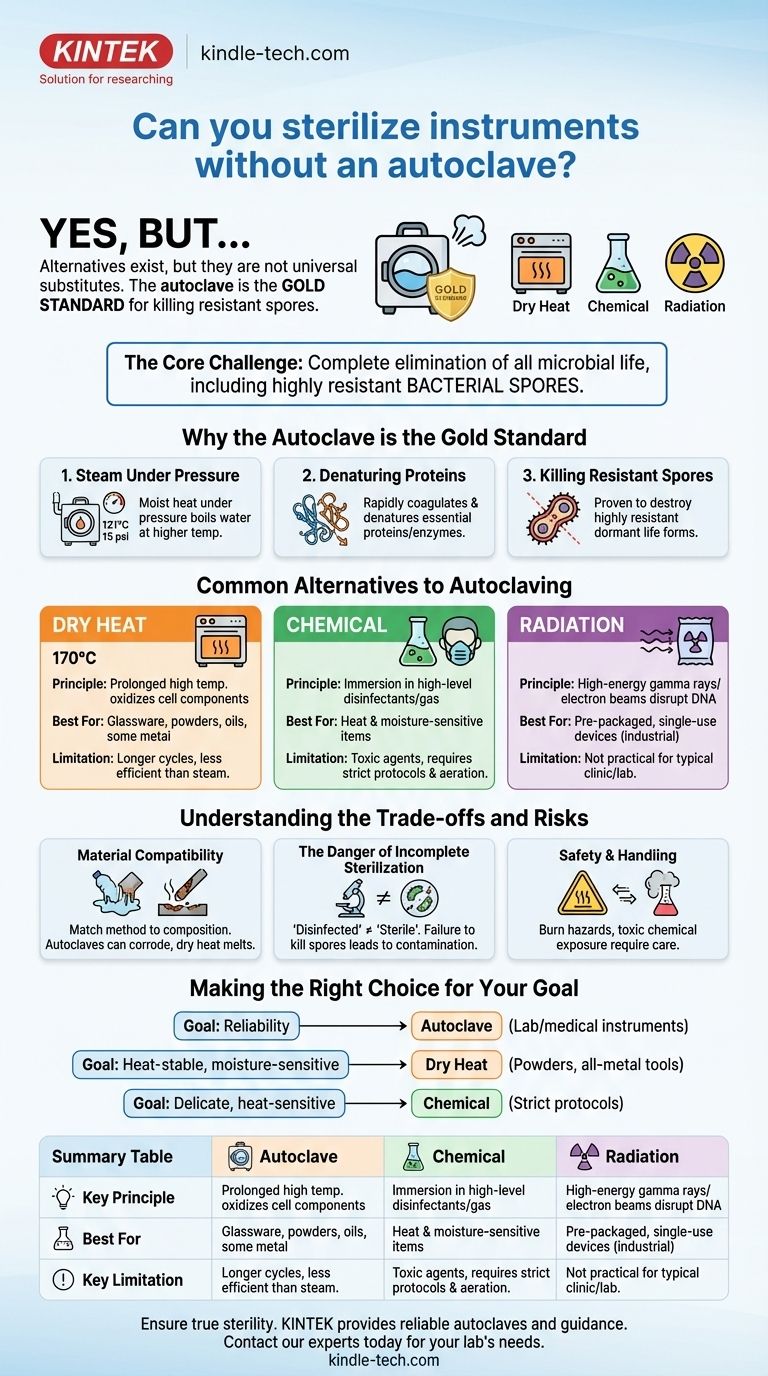

Yes, it is possible to sterilize instruments without an autoclave, but the alternatives are not universal substitutes. While the autoclave is the gold standard for its ability to kill even the most resistant bacterial spores using steam under pressure, other methods exist that use dry heat, chemical agents, or radiation. The correct choice depends entirely on the material of the instrument being sterilized and the resources available.

The core challenge of sterilization isn't just killing bacteria; it's the complete elimination of all microbial life, including highly resistant spores. While an autoclave achieves this with pressurized, moist heat, its alternatives come with critical trade-offs in material compatibility, safety, and effectiveness that you must understand to ensure true sterility.

Why the Autoclave is the Gold Standard

To understand the alternatives, we must first recognize the benchmark for performance. The autoclave’s effectiveness is rooted in a simple but powerful physical principle.

The Principle: Steam Under Pressure

An autoclave does not simply use heat; it uses moist heat under pressure. By increasing the pressure within its chamber, it allows water to boil at a much higher temperature, typically 121°C (250°F) at 15 psi.

The Mechanism: Denaturing Proteins

This high-temperature, high-pressure steam is exceptionally effective at penetrating materials. It rapidly transfers thermal energy, which coagulates and denatures essential proteins and enzymes within microorganisms, killing them far more efficiently than dry heat at the same temperature.

The Target: Killing Resistant Spores

The primary reason autoclaving is the preferred method in medical and laboratory settings is its proven ability to destroy bacterial spores. These dormant, highly resistant life forms can survive boiling and many chemical disinfectants, but they cannot withstand the conditions inside a properly operated autoclave.

Common Alternatives to Autoclaving

When an autoclave is unavailable or unsuitable for the material, other validated methods can be used. Each serves a different purpose.

Dry Heat Sterilization

This method uses a specialized oven to sterilize items with prolonged exposure to high temperatures, typically 170°C (340°F) for at least one hour. It works by oxidizing cell components.

Dry heat is best suited for materials that can be damaged by moisture but can tolerate high temperatures, such as glassware, powders, oils, and some metal instruments. It is less efficient than steam and requires longer cycle times.

Chemical Sterilization

For instruments that are sensitive to both heat and moisture, chemical sterilization is a necessary alternative. This involves full immersion in a high-level disinfectant or exposure to a sterilizing gas.

Common agents include glutaraldehyde, peracetic acid, and ethylene oxide (EtO) gas. These methods are effective but require strict protocols for handling, immersion time, and, in the case of EtO, post-sterilization aeration to remove toxic residues.

Radiation Sterilization

This is an industrial-scale method primarily used for pre-packaged, single-use medical devices like syringes, sutures, and catheters.

High-energy gamma rays or electron beams disrupt the DNA of microorganisms, ensuring sterility without raising the product's temperature significantly. This is not a practical alternative for a typical clinic or lab setting but is a critical part of the medical supply chain.

Understanding the Trade-offs and Risks

Choosing a sterilization method is not a matter of preference; it is a technical decision with significant consequences.

Method vs. Material Compatibility

The most significant factor is the composition of your instrument. Using dry heat on plastics will melt them. Using liquids on sensitive electronics will destroy them. An autoclave can corrode certain low-grade metals. You must match the method to the material.

The Danger of Incomplete Sterilization

"Disinfected" is not "sterile." Many methods can clean an instrument, but if they fail to kill bacterial spores, the instrument is not sterile. This can lead to sample contamination in a lab or life-threatening infections in a clinical setting.

Safety and Handling Concerns

Alternatives carry their own risks. Dry heat ovens present a significant burn hazard. Chemical sterilants are often toxic, corrosive, and require careful handling in well-ventilated areas to avoid user exposure.

Making the Right Choice for Your Goal

Select your sterilization method based on a clear understanding of your instrument's material and your operational requirements.

- If your primary focus is reliability for most lab/medical instruments: The autoclave remains the undisputed standard for its efficiency and effectiveness against spores.

- If you are sterilizing heat-stable, moisture-sensitive items (like powders or all-metal tools): Dry heat sterilization is a robust and effective alternative.

- If you must sterilize delicate, heat-sensitive instruments: Chemical sterilization is the most appropriate choice, but it demands strict adherence to safety protocols.

Ultimately, understanding the principles behind each method empowers you to select the safest and most effective approach for your specific application.

Summary Table:

| Sterilization Method | Key Principle | Best For | Key Limitation |

|---|---|---|---|

| Autoclave (Gold Standard) | Steam under pressure (121°C) | Most lab/medical instruments; kills spores | Not suitable for moisture/heat-sensitive items |

| Dry Heat | Prolonged high temperatures (e.g., 170°C) | Glassware, powders, oils, metal tools | Longer cycle times; less efficient than steam |

| Chemical | Immersion in liquid sterilants (e.g., glutaraldehyde) | Heat-sensitive, delicate instruments | Toxic chemicals; requires strict handling protocols |

| Radiation | Gamma rays or electron beams | Pre-packaged, single-use medical devices | Industrial-scale; not practical for typical labs |

Ensure true sterility and protect your valuable lab equipment. Choosing the right sterilization method is critical for safety and results. KINTEK specializes in lab equipment and consumables, providing reliable autoclaves and guidance on the best sterilization solutions for your specific instruments and materials. Contact our experts today to discuss your lab's sterilization needs and ensure complete peace of mind.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the function of high-pressure autoclaves in IASCC testing? Ensure Nuclear Material Safety

- What media cannot be autoclaved? Protect Heat-Sensitive Reagents from Sterilization Damage

- What core conditions must a high-pressure autoclave meet for supercritical water corrosion? Master 27 MPa & 600°C Tests

- What is the function of autoclave in tissue culture laboratory? Ensure Absolute Sterility for Successful Cell Growth

- What are the advantages of Molybdenum for autoclave construction? Superior Purity & Chemical Stability in Nitride Synthesis

- What is the principle of autoclave in microbiology? The Key to Complete Sterilization

- What is the function of autoclaves in self-healing cement? Ensure Pure MICP for Superior Biomineralization

- Why is 121 degrees used in autoclave? The Science Behind Reliable Sterilization