Choosing the right agitator is a critical engineering decision that dictates the success of your entire reactor process. You select an agitator by first defining your primary process objective—such as blending liquids, suspending solids, or dispersing gas—and then matching an impeller type and its resulting flow pattern to your fluid's specific properties, most importantly its viscosity.

The core principle of agitator selection is not about picking a piece of hardware, but about generating the correct fluid motion. The ultimate goal is to match the flow pattern produced by the impeller (axial or radial) to the specific requirements of your process and the viscosity of your fluid.

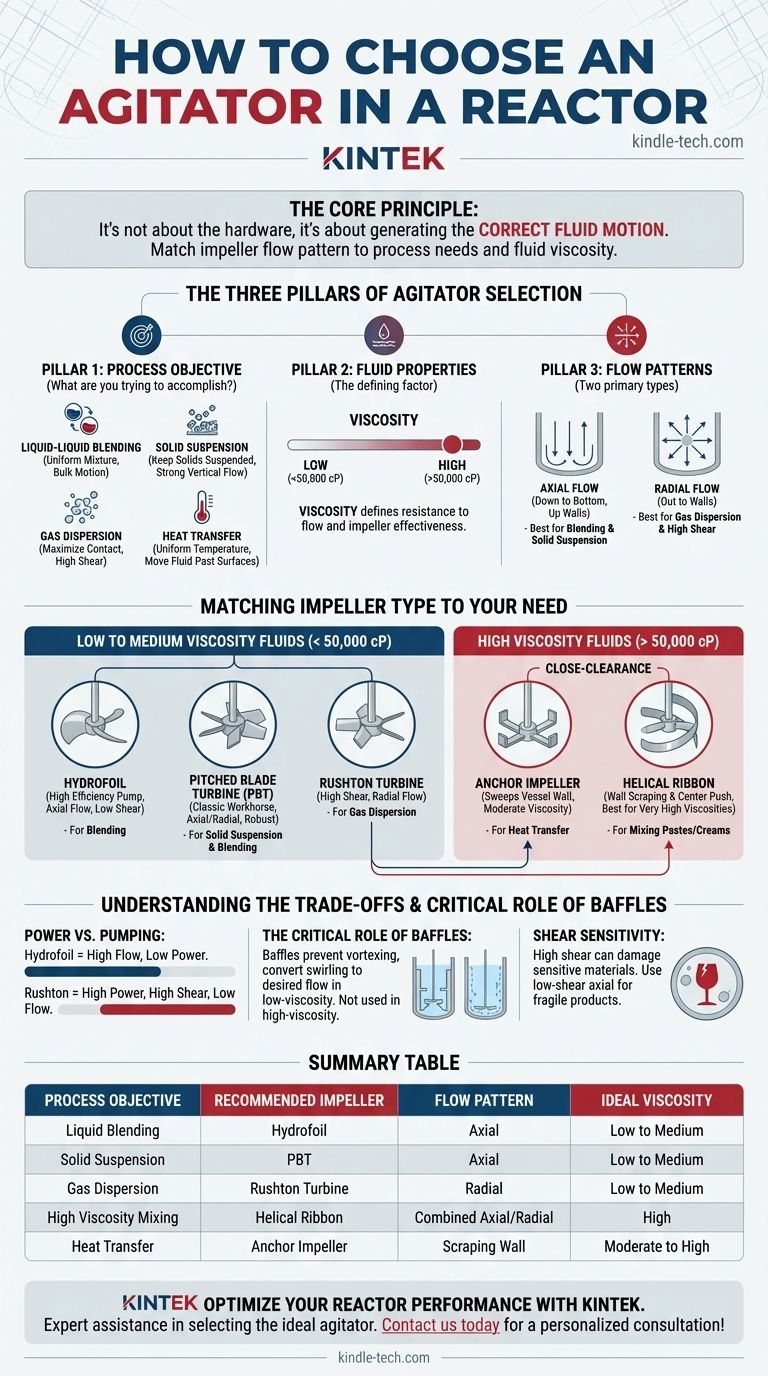

The Three Pillars of Agitator Selection

To choose an agitator systematically, you must evaluate three fundamental aspects of your system: the process goal, the fluid properties, and the required flow pattern.

Pillar 1: Defining Your Process Objective

The first question is always: what are you trying to accomplish? Each objective requires a different type of fluid motion.

- Liquid-Liquid Blending: The goal is to create a uniform mixture from two or more miscible liquids. This requires bulk fluid motion to turn over the entire tank volume efficiently.

- Solid Suspension: The goal is to keep solid particles suspended uniformly within the liquid, preventing them from settling at the bottom of the reactor. This requires strong vertical flow currents.

- Gas Dispersion: The goal is to break up a stream of gas into fine bubbles and disperse them throughout the liquid to maximize the gas-liquid contact area, which is crucial for many reactions. This requires high local shear.

- Heat Transfer: The goal is to ensure a uniform temperature throughout the reactor, typically by moving fluid past heat exchange surfaces like a jacket or internal coils.

Pillar 2: Characterizing Your Fluid

The properties of the fluid itself are the single largest factor determining the type of impeller you can use.

Viscosity is the most critical property. It defines the fluid's resistance to flow and dictates which impeller style will be effective. A low-viscosity fluid (like water) is easy to pump, while a high-viscosity fluid (like honey or a thick polymer paste) resists motion.

We can generally split applications into two groups: low-to-medium viscosity (< 50,000 cP) and high viscosity (> 50,000 cP).

Pillar 3: Understanding Flow Patterns

Impellers are designed to generate one of two primary flow patterns.

- Axial Flow: This pattern directs fluid downward toward the bottom of the tank before it flows up the vessel walls. It is excellent for bulk motion and is ideal for blending and solid suspension. Impellers that create this pattern are often called high-flow or high-pumping impellers.

- Radial Flow: This pattern directs fluid outward toward the vessel walls. This creates high shear near the impeller but is less efficient at generating top-to-bottom tank turnover. It is ideal for gas dispersion and creating emulsions.

Matching Impeller Type to Your Need

With the fundamentals established, you can now map specific impeller hardware to your application.

For Low to Medium Viscosity Fluids (< 50,000 cP)

These applications use "open" style turbines that move fluid efficiently in a large, unbaffled tank (though baffles are almost always required).

- Hydrofoils: These are the modern standard for blending. Their curved, profiled blades generate excellent axial flow with very low power consumption, making them highly efficient.

- Pitched Blade Turbines (PBTs): A classic workhorse impeller. The PBT has flat blades angled to produce a strong axial flow with some radial component. It is excellent for solid suspension and general blending.

- Rushton Turbines: This is the classic high-shear impeller. Its vertical flat blades create a strong radial flow, which is perfect for breaking up gas bubbles in gas dispersion applications.

For High Viscosity Fluids (> 50,000 cP)

In thick, viscous fluids, open turbines are ineffective; they simply carve a hole in the fluid. These applications require "close-clearance" impellers that physically contact or pass close to the vessel wall.

- Anchor Impellers: This simple, two-bladed agitator sweeps the vessel wall, providing mixing and improving heat transfer at the wall. It is best for moderate viscosity where some top-to-bottom mixing is still possible.

- Helical Ribbons: This is the superior choice for very high viscosities. The outer ribbon scrapes the wall and lifts the fluid, while an inner ribbon or screw pushes fluid down the center. This combination creates positive, predictable turnover in materials that would otherwise not flow.

Understanding the Trade-offs

Choosing an agitator involves balancing competing factors. An ideal choice in one area may be a poor choice in another.

Power vs. Pumping

There is a direct trade-off between an impeller's ability to pump fluid (flow) and the power it consumes.

A hydrofoil is a high-efficiency pump. It generates a high flow rate for a very low power input, but it creates very little shear.

A Rushton turbine, by contrast, is a poor pump. It consumes a very high amount of power to generate its high-shear radial flow but is ineffective at creating bulk tank turnover.

The Critical Role of Baffles

In low-viscosity applications, an unbaffled tank will lead to a vortex (swirling), where the fluid rotates with the impeller. This results in almost no actual mixing.

Baffles—vertical plates installed on the tank wall—are essential to break this rotation and convert the swirling motion into the desired axial or radial flow, ensuring proper top-to-bottom mixing. In high-viscosity applications with close-clearance impellers, baffles are typically not needed or used.

Shear Sensitivity

The high shear created by a Rushton turbine can be destructive to certain products. Shear-sensitive materials, such as cells in a bioreactor or long-chain polymers, can be damaged or destroyed by intense agitation. For these processes, a low-shear axial flow impeller is required.

Making the Right Choice for Your Goal

Ultimately, your choice should be a direct solution to your primary process objective.

- If your primary focus is efficient liquid blending: Choose a high-efficiency hydrofoil impeller to achieve rapid tank turnover with minimal power cost.

- If your primary focus is suspending solids or general-purpose mixing: A pitched blade turbine (PBT) is a robust and effective choice.

- If your primary focus is dispersing gas into a low-viscosity liquid: Use a Rushton turbine to provide the high shear needed to create fine bubbles.

- If your primary focus is mixing high-viscosity pastes or creams: A helical ribbon agitator is the most effective solution for ensuring complete product turnover.

By systematically evaluating your process, fluid, and desired flow pattern, you can select an agitator with engineering precision.

Summary Table:

| Process Objective | Recommended Impeller Type | Flow Pattern | Ideal For Viscosity |

|---|---|---|---|

| Liquid Blending | Hydrofoil | Axial | Low to Medium (<50,000 cP) |

| Solid Suspension | Pitched Blade Turbine (PBT) | Axial | Low to Medium (<50,000 cP) |

| Gas Dispersion | Rushton Turbine | Radial | Low to Medium (<50,000 cP) |

| High Viscosity Mixing | Helical Ribbon | Combined Axial/Radial | High (>50,000 cP) |

| Heat Transfer | Anchor Impeller | Scraping Wall | Moderate to High Viscosity |

Optimize Your Reactor Performance with KINTEK

Choosing the correct agitator is critical for achieving consistent results, whether you're blending, suspending solids, dispersing gas, or handling high-viscosity materials. KINTEK specializes in providing high-quality lab equipment and consumables, including precisely engineered agitators and reactors tailored to your specific process needs. Our experts can help you select the ideal impeller type and configuration to maximize efficiency, ensure product quality, and scale your processes successfully.

Let our team help you design the perfect mixing solution for your laboratory. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the role of a ceramic porous distributor in a hydrolysis fluidized bed reactor? Optimize Your Chemical Yield

- What is the technological value of a dual-stage tandem reactor for Salix biomass? Unlock Higher Methane Yields

- What technical advantages does a high-pressure sealed reactor offer for transesterification? Boost Biodiesel Efficiency

- Why is high-purity nitrogen purging required for PCL polyol reactors? Ensure Successful Polymerization Cycles

- How does a high-temperature vacuum reactor ensure the progression of polymerization? Master PHFA Synthesis Precision

- What is the function of a high-pressure hydrothermal synthesis reactor? Engineering Carbon Aerogel Electrodes

- What necessary conditions does a laboratory high-pressure reactor system provide for CHP cleavage? Optimize Safety and Yield

- Why are nickel-based alloys like Inconel or Hastelloy required for SCW reactors? Ensure Durability in Extreme Environments