To properly clean an autoclave, you must regularly service three main components: the sterilization chamber, the door gasket, and the chamber's drain strainer. This process involves wiping down surfaces with appropriate cleaners, clearing debris from the drain system, and ensuring the water used for steam generation is clean to prevent mineral buildup and system damage.

The goal of cleaning an autoclave is not just cosmetic. It is a critical procedure to ensure sterilization cycles are effective, prevent cross-contamination, and protect the machine from premature failure due to residue and mineral scale.

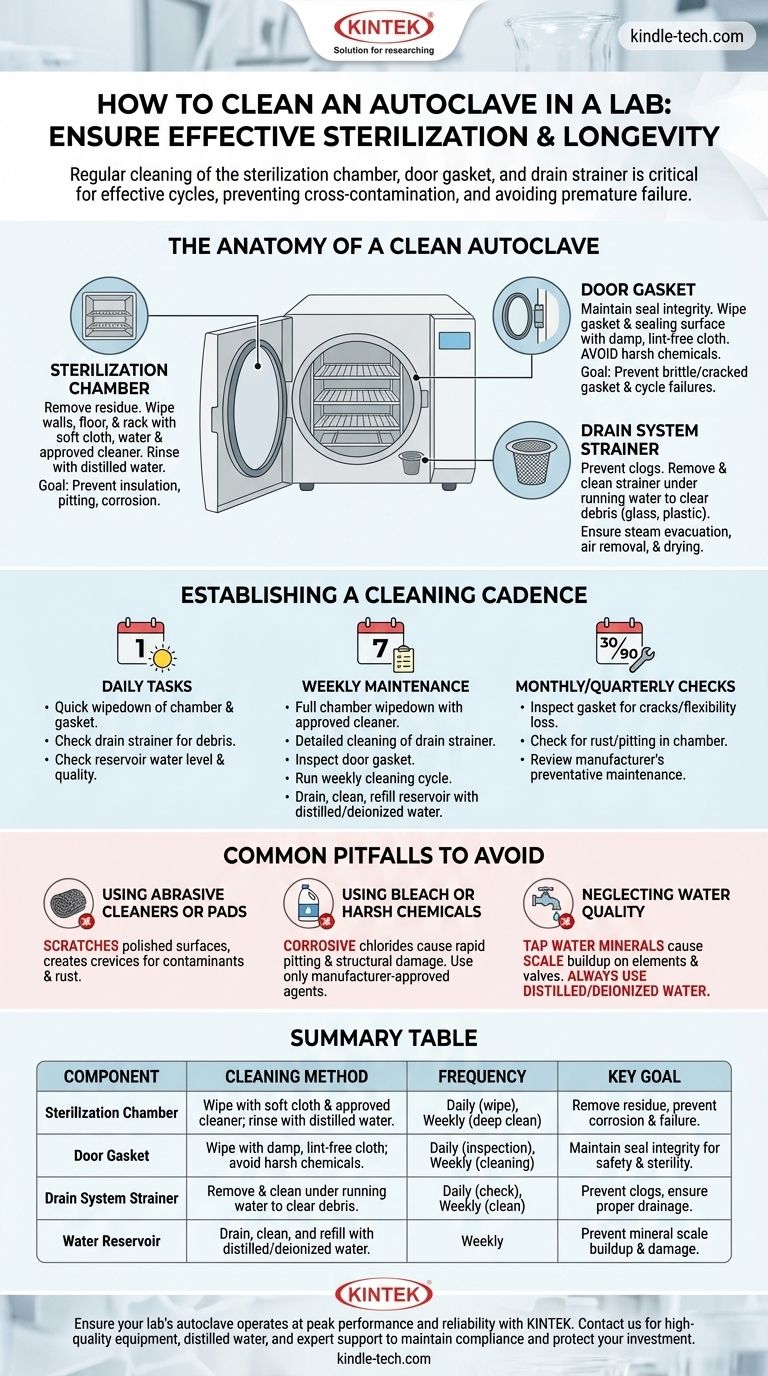

The Anatomy of a Clean Autoclave

Effective cleaning requires understanding which parts are most susceptible to contamination and wear. Focus your efforts on the areas that directly impact sterilization performance and equipment longevity.

The Sterilization Chamber

The chamber is where the work of sterilization happens. Any residue left behind from spills or boil-overs can become baked onto the surface during a cycle.

This baked-on residue can insulate microorganisms from the steam, potentially leading to a failed sterilization cycle. It can also cause pitting and corrosion of the stainless steel chamber over time.

Clean the chamber walls, floor, and rack system with a soft, lint-free cloth, water, and an approved autoclave cleaning solution or a mild detergent. Always rinse thoroughly with distilled or deionized water to remove any cleaning agent residue.

The Door Gasket

The door gasket creates the hermetic seal required to maintain pressure and temperature. It is the gatekeeper of sterility.

Debris, dirt, and sediment can compromise this seal, leading to cycle failures or safety hazards. Over time, a dirty gasket can become brittle, dry, or cracked, requiring replacement.

Wipe the gasket and the corresponding sealing surface on the chamber with a damp, lint-free cloth. Do not use any detergents or cleaning agents on the gasket itself unless explicitly approved by the manufacturer, as they can degrade the material.

The Drain System Strainer

Most autoclaves have a strainer or filter in the chamber drain to catch debris like broken glass, melted plastic, or tape.

If this strainer becomes clogged, it can prevent proper steam evacuation, air removal, and drying. This can lead to wet packs, cycle alarms, and standing water in the chamber, which is a primary source of contamination.

Remove the strainer (usually a simple mesh screen at the bottom of the chamber) and clean it thoroughly under running water. Ensure all debris is removed before placing it back.

Establishing a Cleaning Cadence

Your cleaning frequency depends on your usage patterns and the materials you sterilize. A clinical lab running biological waste will have stricter requirements than a research lab preparing sterile media.

Daily Tasks

For high-throughput or clinical labs, a quick daily wipedown is essential. Check the drain strainer for debris and wipe the door gasket and chamber interior to remove any obvious spills from the day's cycles. If your autoclave uses a reservoir, check the water level and quality.

Weekly Maintenance

Perform a more thorough cleaning once a week. This includes a full wipedown of the chamber interior with a recommended cleaning solution, a detailed cleaning of the drain strainer, and a careful inspection of the door gasket.

Many protocols also call for running a weekly cleaning cycle (an empty sterilization run), often with an approved cleaning agent. This helps flush the internal plumbing and valves with high-temperature steam. For autoclaves with a water reservoir, this is the ideal time to drain, clean, and refill it with fresh distilled or deionized water.

Monthly and Quarterly Checks

On a longer-term basis, inspect for signs of wear and tear. Check the gasket for cracks or loss of flexibility. Look for any signs of rust or pitting in the chamber. This is also a good time to review the manufacturer's guidelines for any scheduled preventative maintenance.

Common Pitfalls to Avoid

Using the wrong methods or materials can cause more harm than good, leading to expensive repairs and invalid sterilization cycles.

Using Abrasive Cleaners or Pads

Never use steel wool, scouring pads, or highly abrasive chemical cleaners inside the chamber. These will scratch the polished stainless steel surface.

Scratches create microscopic crevices where contaminants can hide and rust can begin to form, permanently damaging the chamber and compromising its cleanability.

Using Bleach or Harsh Chemicals

Chlorides and halides, found in bleach and many common lab disinfectants, are extremely corrosive to stainless steel. Using them in an autoclave will cause rapid pitting and structural damage.

Only use cleaning agents specifically formulated for and approved by the autoclave manufacturer. When in doubt, a mild, non-chloride detergent followed by a thorough rinse with purified water is a safe choice.

Neglecting Water Quality

Using tap water is one of the most common causes of autoclave failure. Minerals dissolved in tap water (like calcium and magnesium) precipitate out during steam generation, forming a hard scale.

This scale clogs solenoid valves, coats and damages heating elements, and can flake off to clog the drain strainer. Always use distilled or deionized water to prevent this and dramatically extend the life of your equipment.

Making the Right Choice for Your Goal

Your cleaning protocol should be directly aligned with your lab's primary function to ensure safety and compliance without creating unnecessary work.

- If your primary focus is clinical work or sterilizing biohazards: Adopt a daily and weekly cleaning schedule without compromise to prevent cross-contamination and ensure patient/personnel safety.

- If your primary focus is media preparation or general research: A thorough weekly cleaning is sufficient, but remain vigilant for spills and boil-overs, cleaning them immediately to prevent bake-on.

- If your primary focus is equipment longevity and cost savings: The single most important action is to use only high-purity (distilled or deionized) water for steam generation.

Consistent cleaning is the most effective form of preventative maintenance you can perform on an autoclave.

Summary Table:

| Component | Cleaning Method | Frequency | Key Goal |

|---|---|---|---|

| Sterilization Chamber | Wipe with soft cloth & approved cleaner; rinse with distilled water. | Daily (wipe), Weekly (deep clean) | Remove residue, prevent corrosion & cycle failure. |

| Door Gasket | Wipe with damp, lint-free cloth; avoid harsh chemicals. | Daily (inspection), Weekly (cleaning) | Maintain seal integrity for safety & sterility. |

| Drain System Strainer | Remove & clean under running water to clear debris. | Daily (check), Weekly (clean) | Prevent clogs, ensure proper drainage & drying. |

| Water Reservoir | Drain, clean, and refill with distilled/deionized water. | Weekly | Prevent mineral scale buildup & system damage. |

Ensure your lab's autoclave operates at peak performance and reliability. Proper cleaning is essential, but having the right equipment and consumables is the foundation. KINTEK specializes in high-quality lab equipment and consumables, including autoclaves and the distilled/deionized water necessary to prevent scale and extend their lifespan. Our experts can help you select the right autoclave for your specific needs—whether for clinical work, media preparation, or general research—and provide the support to keep it running smoothly. Contact KINTEK today to discuss your laboratory's sterilization needs and discover how we can help you maintain compliance, ensure safety, and protect your investment.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- Where are autoclaves used? Ensuring Sterility from Hospitals to High-Tech Labs

- What is autoclave features and uses? A Guide to Sterilization and Safety

- Why is autoclaving rather than boiling water used for sterilization? Achieve True Sterility for Your Lab

- How do you sterilise without an autoclave? Effective methods for heat-sensitive materials

- What is process monitoring in the context of a decontamination process? Ensure Safety and Compliance

- Why is a laboratory high-pressure autoclave sterilizer necessary? Ensure Accuracy in Antibacterial Research

- What temperature does an autoclave open? The Critical Safety Rule for Lab Sterilization

- What is the process of autoclave sterilization? Master the Key Steps for 100% Sterility