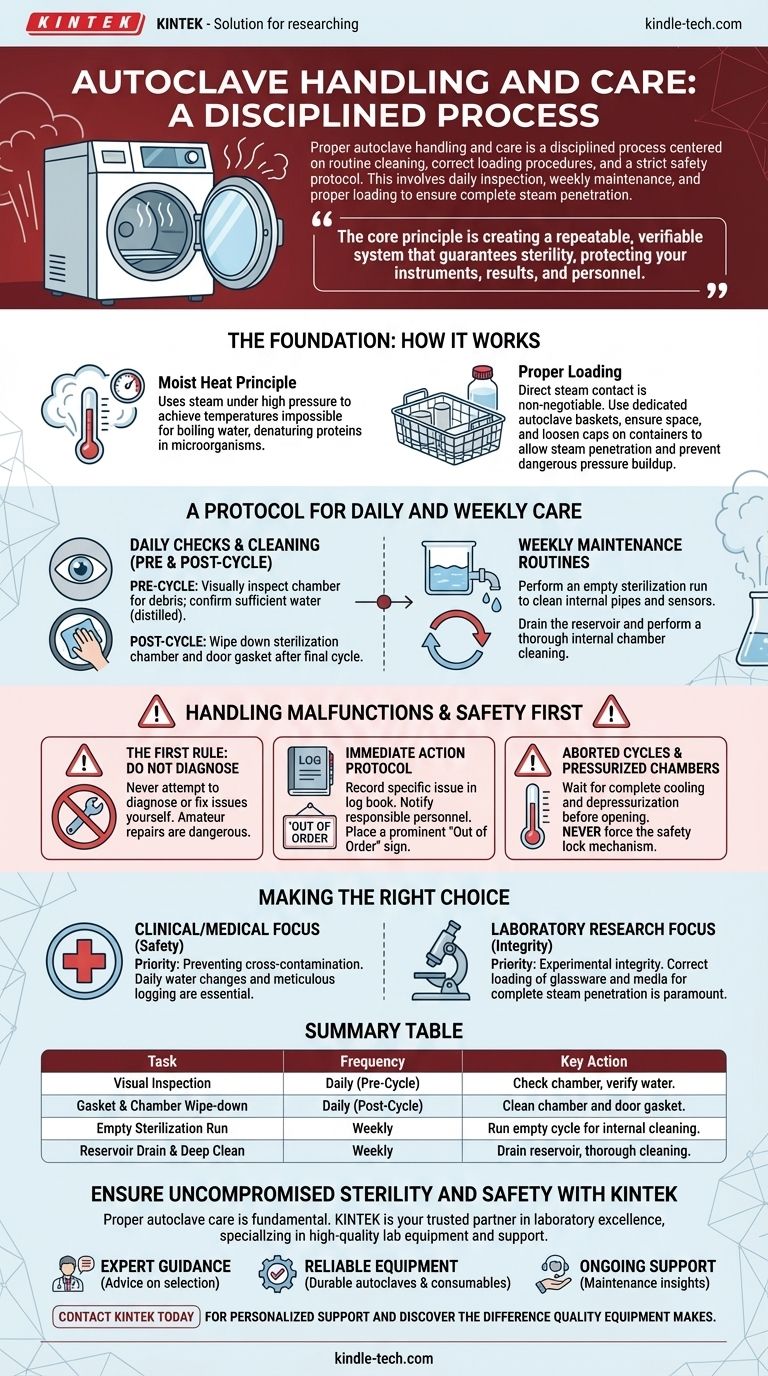

Proper autoclave handling and care is a disciplined process centered on routine cleaning, correct loading procedures, and a strict safety protocol. This involves daily inspection of the chamber and door gasket, weekly maintenance cycles, and ensuring all materials are arranged to allow for complete steam penetration.

The core principle of autoclave management is not just about cleaning the machine, but about creating a repeatable, verifiable system that guarantees sterility. This protects your instruments, your results, and most importantly, your personnel from harm.

The Foundation: How an Autoclave Achieves Sterility

To care for an autoclave properly, you must first understand its fundamental mechanism. Its effectiveness depends entirely on the correct application of its core principle.

The Principle of Moist Heat

An autoclave does not simply "bake" items clean. It operates by using steam under high pressure to achieve temperatures that are impossible for boiling water at normal atmospheric pressure.

This combination of moist heat and high pressure effectively denatures the proteins in microorganisms like bacteria and viruses, rendering them sterile.

Why Proper Loading is Non-Negotiable

Effective sterilization requires that pressurized steam make direct contact with every surface of the items inside.

Place all materials in a dedicated autoclave basket, ensuring there is enough space between each item. Nothing should touch the chamber walls or floor.

For bottles or containers with caps, ensure the caps are loosened. A tight seal will prevent steam from entering, leaving the contents unsterilized, and can create a dangerous pressure differential.

A Protocol for Daily and Weekly Care

Consistent maintenance is the most critical factor in an autoclave's longevity and reliability. Simple, regular actions prevent buildup and ensure every cycle runs as intended.

Daily Checks Before Every Cycle

Before running a cycle, perform a quick visual inspection. Confirm the chamber is free of debris from previous runs.

Crucially, check that there is a sufficient amount of the correct type of water (often distilled) as specified by the manufacturer.

Daily Post-Cycle Cleaning

After the final cycle of the day, wipe down the inside of the sterilization chamber and the door gasket. This prevents the buildup of residue that can compromise the door seal over time.

Weekly Maintenance Routines

In clinical or high-use settings, it is essential to perform a weekly empty sterilization run. This helps clean internal pipes and sensors.

Draining the reservoir and performing a more thorough internal chamber cleaning on a weekly basis is also a standard best practice to prevent cross-contamination and biofilm formation.

Handling Malfunctions and Ensuring Safety

An autoclave malfunction can be hazardous if handled improperly. A strict, non-negotiable protocol is essential for safety.

The First Rule: Do Not Diagnose

If the autoclave malfunctions or displays an error, do not attempt to diagnose or fix the issue yourself. Modern autoclaves are complex, and amateur repairs can lead to further damage or serious injury.

The Immediate Action Protocol

Immediately record the specific issue in the autoclave's log book. Notify the laboratory manager or responsible personnel.

Finally, place a clear and prominent "Out of Order" sign on the unit to prevent anyone else from attempting to use it.

Aborted Cycles and Pressurized Chambers

If a cycle is aborted, you must still wait for the unit to completely cool and depressurize before opening it.

Never, under any circumstances, attempt to force the safety lock mechanism open. The chamber remains a high-pressure, high-temperature environment that can cause severe steam burns and injury.

Making the Right Choice for Your Goal

Your specific application will determine which aspects of autoclave care are most critical to your daily work.

- If your primary focus is clinical or medical safety: Your priority is preventing cross-contamination, making daily water changes and meticulous logging of every cycle absolutely essential.

- If your primary focus is laboratory research: Your goal is experimental integrity, so ensuring complete steam penetration by correctly loading glassware and media is paramount to achieving valid results.

Consistent and mindful care transforms the autoclave from a simple machine into a reliable cornerstone of your professional standards.

Summary Table:

| Task | Frequency | Key Action |

|---|---|---|

| Visual Inspection | Daily (Pre-Cycle) | Check chamber for debris, verify water level. |

| Gasket & Chamber Wipe-down | Daily (Post-Cycle) | Clean chamber and door gasket to prevent residue. |

| Empty Sterilization Run | Weekly | Run an empty cycle to clean internal pipes and sensors. |

| Reservoir Drain & Deep Clean | Weekly | Drain water reservoir and perform thorough chamber cleaning. |

Ensure Uncompromised Sterility and Safety in Your Lab

Proper autoclave care is fundamental to protecting your personnel, your experiments, and your valuable instruments. The protocols outlined above are your first step toward achieving reliable, repeatable sterility.

KINTEK is your trusted partner in laboratory excellence. We specialize in providing high-quality lab equipment and consumables, including autoclaves and the support needed to maintain them.

Let us help you build a safer, more efficient lab:

- Expert Guidance: Get advice on selecting the right autoclave for your specific clinical or research needs.

- Reliable Equipment: Source durable autoclaves and genuine consumables from a trusted supplier.

- Ongoing Support: Ensure your equipment operates at peak performance with proper maintenance insights.

Ready to enhance your sterilization protocols? Contact KINTEK today for personalized support and discover the difference quality equipment makes.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

People Also Ask

- What materials are used in sterilization? Match the Right Method to Your Lab Equipment

- Why are autoclaves utilized for the hydrothermal synthesis of core-shell PCMs? Achieving Superior Shell Integrity

- What is the purpose of the autoclave test? Ensuring Sterilization Effectiveness and Safety

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- Which instrument Cannot be autoclaved? Protect Your Lab Equipment from Sterilization Damage

- What is the main purpose of the autoclave in a laboratory? To Achieve Absolute Sterilization with High-Pressure Steam

- What is the research value of using a high-pressure autoclave for curing geopolymer materials? Unlocking Durability

- What is the lifespan of an autoclave? Maximize Your Equipment's Lifespan with Expert Care