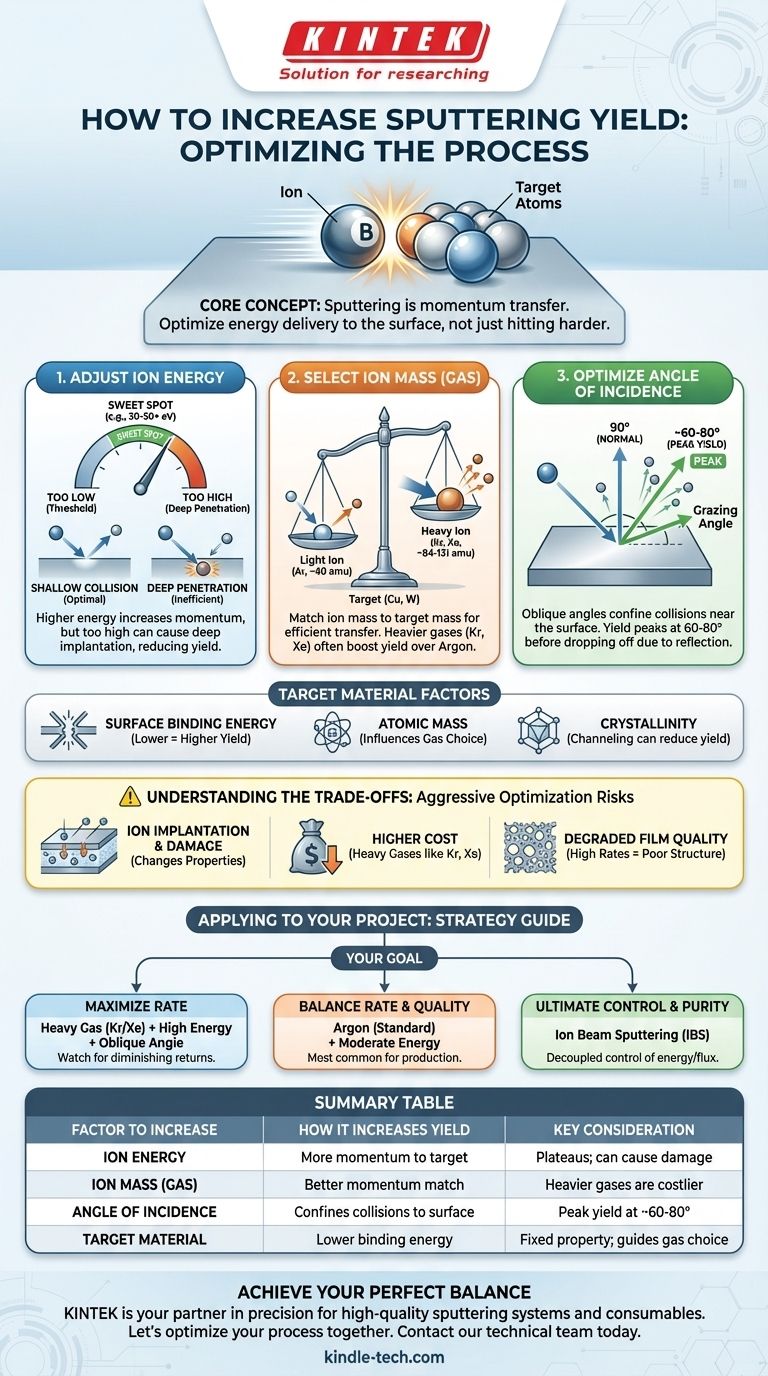

To directly increase sputtering yield, you must optimize the three primary variables of the process: increase the energy of the bombarding ions, increase the mass of those ions (by choosing a heavier sputtering gas), and adjust the ion's angle of incidence on the target. These factors directly control the efficiency of the momentum transfer from the ion to the target atoms.

Sputtering is fundamentally a physical process of momentum transfer. Increasing the sputtering yield is not just about hitting the target harder, but about delivering the optimal amount of kinetic energy to the target's surface atoms to eject them efficiently without wasting energy deep within the material.

The Core Levers for Controlling Sputtering Yield

To understand how to increase sputtering yield, you must treat it as a system with several interconnected variables. Adjusting one will often have consequences for the others and for your final film properties.

H3: Adjusting Ion Energy

The kinetic energy of the bombarding ions is the most direct control you have over the process. A sputtering process will not begin until the ions have enough energy to overcome the surface binding energy of the target atoms, typically requiring a threshold of 30-50 eV.

Above this threshold, increasing ion energy generally increases the sputtering yield because each ion carries more momentum into the collision.

However, this effect is not infinite. At very high energies (e.g., above a few thousand eV), ions penetrate too deeply into the target. This deposits energy far below the surface, where it cannot contribute to ejecting surface atoms, causing the yield to plateau or even decrease.

H3: Selecting the Sputtering Gas (Ion Mass)

The efficiency of momentum transfer depends heavily on the relative masses of the ion and the target atom. To maximize the energy transferred in a collision, the mass of the sputtering ion should be as close as possible to the mass of the target atom.

For this reason, choosing a heavier inert gas can significantly boost sputtering yield. A typical process might use Argon (Ar, mass ≈ 40 amu). Switching to Krypton (Kr, mass ≈ 84 amu) or Xenon (Xe, mass ≈ 131 amu) provides a better mass match for many common metal targets (e.g., Copper, Titanium, Tungsten), resulting in a higher yield.

H3: Optimizing the Angle of Incidence

Directly striking a target at a 90° angle (normal incidence) is not always the most efficient method. As the angle of incidence becomes more oblique (further from 90°), an ion's path is more likely to be confined near the surface.

This increases the probability of collisions that lead to atom ejection rather than deep penetration. Sputtering yield typically increases with the angle of incidence up to a peak (often around 60-80° off-normal), after which it drops off sharply as the ions begin to simply reflect off the surface.

H3: Accounting for the Target Material

While you often cannot change your target material, its properties dictate the upper limit of the sputtering yield. Key factors include:

- Surface Binding Energy: Materials with lower binding energy require less energy to eject an atom, leading to a higher yield.

- Atomic Mass: As discussed, the mass of the target atoms influences which sputtering gas will be most effective.

- Crystallinity: For crystalline targets, the yield can depend on the orientation of the crystal lattice. If ions enter along a "channel" in the crystal structure, they can travel deep into the target with few collisions, reducing the surface sputtering effect.

Understanding the Trade-offs

Aggressively maximizing sputtering yield to increase deposition rate can have unintended and often negative consequences for your process and final film quality.

H3: Higher Ion Energy Can Cause Damage

While higher energy boosts yield, it can also lead to ion implantation, where high-energy gas ions become embedded in your growing film. This changes the film's chemical and physical properties. It can also cause lattice damage in the film or the underlying substrate.

H3: Heavier Gases Have Downsides

Krypton and Xenon are significantly more expensive than Argon, which can make a process uneconomical at scale. Furthermore, like high-energy ions, these heavier atoms are more prone to becoming entrapped in the film, which can alter film stress and other material properties.

H3: High Rates Can Degrade Film Quality

A very high sputtering yield translates to a high deposition rate. If the atoms arrive at the substrate too quickly, they may not have sufficient time to arrange themselves into a dense, well-ordered film structure. This can result in a more porous film with higher internal stress and poorer adhesion.

How to Apply This to Your Project

Your strategy should be guided by your ultimate goal, whether it's raw speed, film quality, or process control.

- If your primary focus is maximizing deposition rate: Use the heaviest sputtering gas practical (Krypton or Xenon) and increase the ion energy, but watch for the point of diminishing returns where the yield plateaus. Experiment with off-normal target angles to find the peak yield.

- If your primary focus is balancing rate with film quality: Start with Argon, the industry standard. Moderately increase your ion energy and power to find a stable rate that produces good films. This balanced approach is the most common for production environments.

- If your primary focus is ultimate control and film purity: Consider a technique like Ion Beam Sputtering (IBS). This decouples the plasma generation from the target, allowing you to independently and precisely control ion energy and ion flux, providing the highest degree of control over your film's properties.

Ultimately, mastering sputtering yield is about precisely controlling momentum transfer to achieve your desired balance between deposition rate and final film quality.

Summary Table:

| Factor to Increase | How it Increases Yield | Key Consideration |

|---|---|---|

| Ion Energy | More momentum transferred to target atoms | Plateaus at high energy; can cause film damage |

| Ion Mass (Gas) | Better momentum match with target atoms | Heavier gases (Kr, Xe) are more expensive |

| Angle of Incidence | Confines collisions near the surface | Peak yield at ~60-80°; drops off sharply after |

| Target Material | Lower binding energy = higher yield | Fixed property; dictates optimal gas choice |

Achieve Your Perfect Balance of Deposition Rate and Film Quality

Mastering sputtering yield is critical for efficient thin-film deposition. Whether your priority is maximizing speed for high-throughput production or achieving the ultimate in film purity and control, the right lab equipment is essential.

KINTEK is your partner in precision. We specialize in high-quality sputtering systems and consumables for laboratories focused on R&D and production. Our experts can help you select the ideal configuration—from standard argon setups to advanced ion beam sputtering (IBS) solutions—to meet your specific material science goals.

Let's optimize your process together. Contact our technical team today to discuss how our sputtering equipment can enhance your research and development outcomes.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What types of sensitive medical articles can be stored in ULT freezers? Preserve Critical Samples at -80°C

- What is the temperature range of a lab furnace? From 1100°C to 1800°C+

- Why is a vacuum distillation system necessary during the synthesis of rosin allyl esters? Protect Product Integrity

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the hazards of infrared spectroscopy? Understanding Sample Prep and Instrument Safety

- What are batch type furnaces? A Guide to Flexible, Controlled Thermal Processing

- What role do thermostatic shakers and Erlenmeyer flasks play in bioconversion? Optimize Your Xylose to Xylitol Process

- Why is a controlled drying oven used at a low temperature of 50°C for mineral products? Ensure Sample Integrity