At its core, an autoclave sterilizes instruments and equipment by using high-pressure steam. This process is far more effective than simple boiling water because the pressure allows the steam to reach temperatures high enough (typically 121°C or 250°F) to destroy all microbial life, including highly resistant bacterial spores.

The fundamental principle is not just heat, but the use of pressurized saturated steam. This steam acts as a highly efficient vehicle for transferring thermal energy, ensuring it penetrates every surface of the load and irreversibly damages the essential proteins of microorganisms.

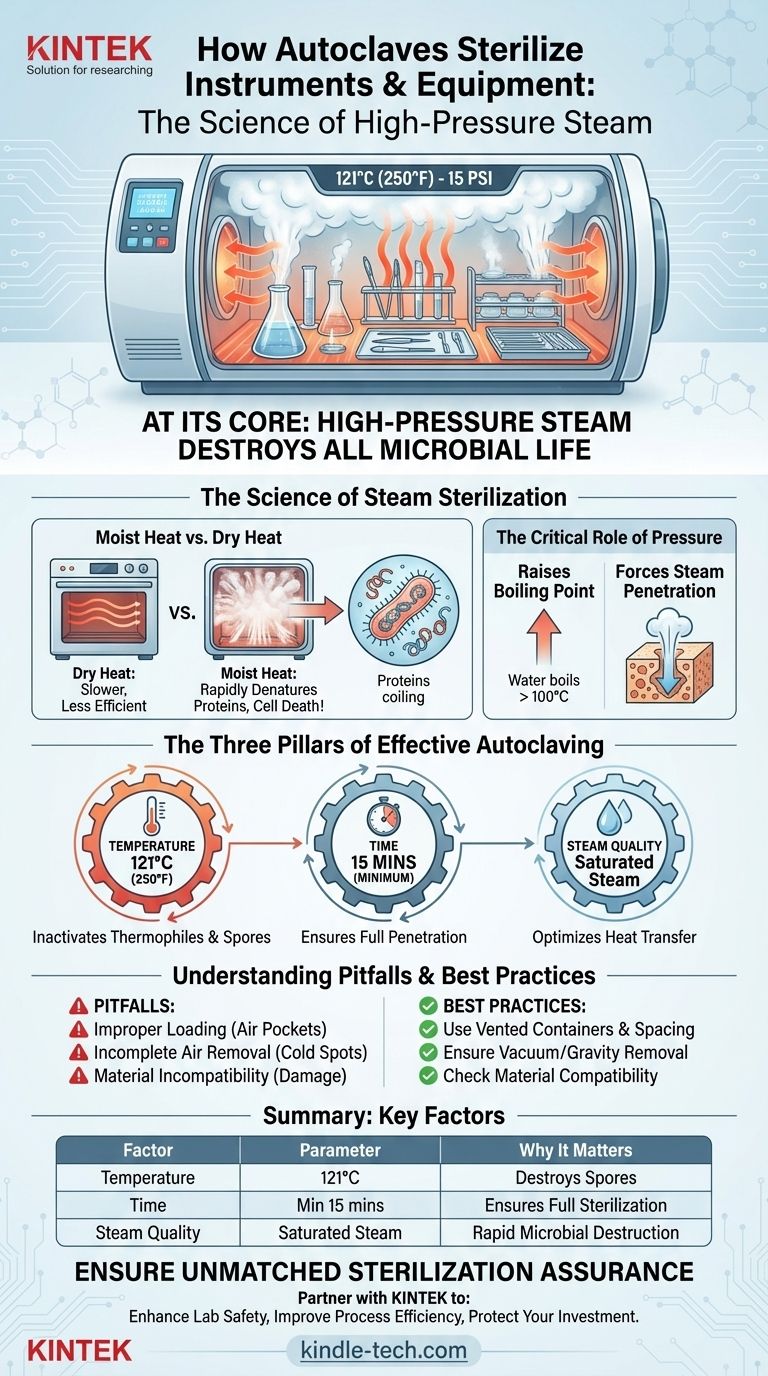

The Science of Steam Sterilization

To understand why autoclaving is the gold standard for sterilization, we must first distinguish it from other heating methods. The combination of moisture and pressure is the key to its effectiveness.

Why Not Just Dry Heat? The Power of Moist Heat

Dry heat can sterilize, but it is a much slower and less efficient process. Moist heat, in the form of steam, is a superior sterilizing agent.

The moisture in steam dramatically accelerates the transfer of heat energy. This moist heat rapidly coagulates and denatures the essential proteins and enzymes within microorganisms, causing irreversible damage and cell death.

The Critical Role of Pressure

Pressure inside an autoclave serves two vital functions. First, it raises the boiling point of water well above 100°C (212°F), allowing the steam to achieve the high temperatures required for sterilization.

Second, the pressure actively helps force the steam to penetrate dense materials and complex instrument parts, ensuring it reaches surfaces that might be shielded in a non-pressurized environment.

The Three Pillars of Effective Autoclaving

Successful sterilization depends on the precise control of three interconnected factors. Failure in any one of these pillars will compromise the entire process.

Pillar 1: Temperature

The standard temperature for autoclaving is 121°C (250°F). This temperature is proven to be high enough to inactivate even the most heat-resistant organisms, known as thermophiles, and tough bacterial spores.

Pillar 2: Time

The duration of the sterilization cycle is critical. A minimum exposure time of 15 minutes at 121°C is the most common baseline.

However, this time must be adjusted based on the size, shape, and density of the load. Larger or more tightly packed loads require longer cycles to ensure the steam fully penetrates the center of the pack.

Pillar 3: Steam Quality

The ideal state for sterilization is saturated steam, which is steam holding the maximum amount of water vapor possible at a given temperature and pressure.

If the steam is too dry ("superheated"), its heat transfer ability is reduced. If it is too wet, it can leave loads damp, creating a potential pathway for recontamination after the cycle is complete.

Understanding the Trade-offs and Pitfalls

While highly reliable, the autoclave process is not foolproof. Success depends on proper procedure and an understanding of its limitations.

Improper Loading

Overloading an autoclave or packing items too densely is a common cause of sterilization failure. This can create air pockets that act as insulators, preventing steam from making direct contact with all surfaces.

Using approved containers, like vented stainless steel boxes, and leaving adequate space between items is essential for allowing steam circulation.

Incomplete Air Removal

Before the sterilization phase begins, all air must be removed from the autoclave chamber. Any residual air can prevent steam from reaching its target temperature and pressure, creating "cold spots" where microorganisms can survive. Modern autoclaves use vacuum cycles or gravity displacement methods to ensure complete air removal.

Material Incompatibility

The high temperature and pressure of an autoclave can damage certain materials. Heat-sensitive plastics, some electronics, and sharp-edged instruments that can be dulled by the process may require alternative sterilization methods.

Making the Right Choice for Your Goal

Applying these principles correctly ensures the complete sterility of your instruments and supplies. Your approach should be guided by the nature of the items being sterilized.

- If your primary focus is routine instruments: Strictly follow the standard cycle (121°C, 15 psi, 15+ minutes) and prioritize proper loading techniques to avoid air pockets.

- If you are sterilizing large or dense loads: Increase the cycle time according to validated protocols to guarantee full steam penetration to the core of the load.

- If you are validating a process or troubleshooting failures: Use chemical and biological indicators placed in the most challenging parts of the load to confirm that the three pillars—time, temperature, and steam contact—were fully achieved.

When its core principles are respected, the autoclave provides an unmatched level of sterilization assurance.

Summary Table:

| Key Factor | Critical Parameter | Why It Matters |

|---|---|---|

| Temperature | 121°C (250°F) | High enough to destroy even the most heat-resistant bacterial spores. |

| Time | Minimum 15 minutes | Ensures steam fully penetrates and sterilizes the entire load. |

| Steam Quality | Saturated Steam | Optimizes heat transfer for rapid and effective microbial destruction. |

Ensure Unmatched Sterilization Assurance for Your Laboratory

Mastering the principles of autoclaving is critical for laboratory safety and integrity. KINTEK specializes in providing reliable lab equipment and consumables to meet your precise sterilization needs.

Partner with KINTEK to:

- Enhance Lab Safety: Achieve complete sterility with equipment designed for optimal performance.

- Improve Process Efficiency: Get expert guidance on selecting the right autoclave and validating your cycles.

- Protect Your Investment: Ensure the longevity of your sensitive instruments with the right sterilization solutions.

Don't leave your sterilization process to chance. Contact our experts today to find the perfect autoclave solution for your laboratory's unique requirements.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What should be autoclaved in a lab? A Guide to Safe and Effective Sterilization

- When should you replace an autoclave? A guide to ensure safety, efficiency, and compliance.

- Why is an Autoclave essential for simulating nuclear reactor conditions during the corrosion testing of zirconium alloys?

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What precautions should be taken when using an autoclave in the laboratory? A Guide to Safe Sterilization

- What is the importance of a Hastelloy high-pressure autoclave? Ensuring Precision in Nuclear Power Research

- How does autoclave work inside? Mastering the Science of Steam Sterilization

- Why is a Teflon-lined high-pressure autoclave required for Mo-Ti-N catalyst synthesis? Ensure Purity and Precision