In essence, an autoclave works by using a combination of high pressure and high temperature to create saturated steam. Inside its sealed chamber, electrical heaters boil water to generate this steam. The intense pressure—typically around 15 PSI above atmospheric pressure—raises the boiling point of water to 121°C (250°F), creating superheated steam that can rapidly penetrate and kill all forms of microbial life, including resilient spores.

An autoclave doesn't just heat items; it leverages a fundamental law of physics. By increasing pressure within a sealed chamber, it forces water to exist as steam at temperatures far above its normal boiling point, ensuring lethal, moist heat penetrates every surface for complete sterilization.

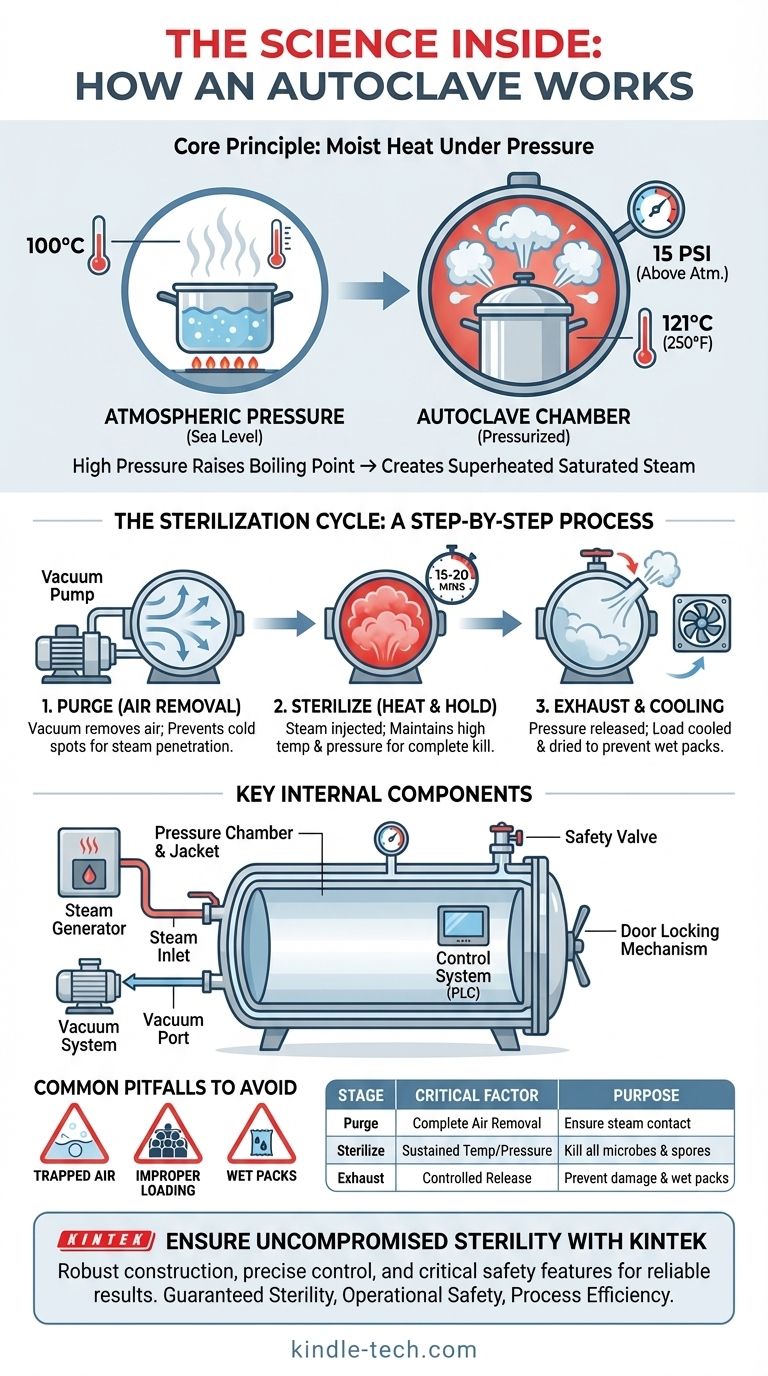

The Core Principle: Moist Heat Under Pressure

To truly understand an autoclave, you must first grasp the scientific principle that makes it so effective. It is far more than a simple oven.

Why Pressure is the Key

At sea level, water boils at 100°C (212°F). An autoclave is a pressure vessel that manipulates this rule. By increasing the internal pressure, it elevates the boiling point of water.

This allows the chamber to be filled with saturated steam at a temperature of 121°C (250°F) or higher, a temperature that is impossible for steam to reach at normal atmospheric pressure.

The Power of Saturated Steam

Moist heat is significantly more effective at sterilization than dry heat. Steam molecules are able to transfer heat energy much more efficiently than dry air, rapidly denaturing the essential proteins and enzymes that all microorganisms rely on to live.

This process is analogous to how a pressure cooker tenderizes tough cuts of meat much faster than a conventional oven. The high-pressure steam forces heat deep into the material quickly and effectively.

A Step-by-Step Look Inside the Sterilization Cycle

A modern autoclave's cycle is a precisely controlled, multi-stage process managed by its control system. Each stage is critical for achieving true sterility.

Stage 1: The Purge (Air Removal)

Before sterilization can begin, all the air inside the chamber must be removed. Air acts as an insulator and its presence creates cold spots, preventing steam from reaching every surface and leading to sterilization failure.

Most modern autoclaves use a vacuum system to actively pump out the air. Simpler models may use a downward displacement method, where incoming steam, which is lighter than air, forces the heavier air out through a drain.

Stage 2: The Sterilization Phase (Heat & Hold)

Once the air is purged, the steam generator injects saturated steam until the chamber reaches the target temperature and pressure (e.g., 121°C at 15 PSI).

The control system then begins a timer—typically 15 to 20 minutes for standard loads. During this "hold time," the high temperature and pressure are precisely maintained to ensure a complete kill of all microbes.

Stage 3: The Exhaust & Cooling Phase

After the hold time is complete, a release valve opens to vent the steam and reduce the internal pressure back to ambient levels. This must be done carefully to avoid boiling over of liquids or damaging sensitive equipment.

The sterilized load is then often put through a short drying phase, using the residual heat of the chamber and sometimes a post-cycle vacuum to remove any remaining moisture. A waste-water cooler ensures the hot condensate is cooled before entering the building's drainage system.

The Key Internal Components and Their Roles

Several critical components work in concert to execute the sterilization cycle safely and reliably.

The Pressure Chamber

This is the core of the autoclave, typically a cylindrical vessel with an inner chamber and an outer "jacket." It is built from thick stainless steel to withstand repeated cycles of high pressure and temperature. The jacket is often filled with steam to help pre-heat the chamber walls and improve temperature uniformity.

The Steam & Vacuum Systems

A dedicated steam generator (or a connection to a central house steam supply) provides the raw material for sterilization. The vacuum system, consisting of a pump and associated valves, is responsible for the critical air removal stage.

The Control System

This is the brain of the autoclave. It can range from a simple microprocessor to a sophisticated Programmable Logic Controller (PLC) with a touchscreen. It precisely opens and closes valves to manage the purge, sterilization, and exhaust phases according to a pre-validated program.

The Safety Mechanisms

Multiple safety features are non-negotiable. A safety valve is designed to automatically release pressure if it exceeds a safe limit. The lid or door has robust locking mechanisms that prevent it from being opened while the chamber is pressurized. A pressure gauge provides a clear visual reading of the internal state.

Understanding the Common Pitfalls

The effectiveness of an autoclave depends on its correct operation. Understanding potential failures is key to ensuring its reliability.

The Enemy: Trapped Air

The single most common cause of sterilization failure is incomplete air removal. If the purge cycle is faulty or if items are wrapped or packed in a way that traps air pockets, the steam cannot make direct contact, and the items will not be sterile.

Improper Loading

Overloading the chamber or packing items too densely prevents steam from circulating freely. This is like trying to cook a tightly packed tray of food in an oven—the items in the middle will remain undercooked. There must be space between all items for steam to penetrate.

Wet Packs

If sterilized packs come out of the autoclave wet, their sterility is compromised. A wet wrapper can act as a wick, drawing microorganisms from the outside environment through to the sterile item inside. This often indicates a problem with the exhaust or drying phase of the cycle.

Applying This to Your Process

Understanding the internal workings of an autoclave empowers you to use it more effectively and troubleshoot potential issues.

- If your primary focus is guaranteed sterility: Recognize that complete air removal is the most critical step. Always ensure the purge or vacuum cycle runs correctly and that items are loaded to prevent air pockets.

- If your primary focus is operational safety: Never attempt to override the door locking mechanisms or tamper with the safety valve. Trust these systems to protect you from the high pressure and temperature inside.

- If your primary focus is process efficiency: Load the autoclave correctly. A properly loaded chamber ensures steam can penetrate all items quickly, preventing the need for longer, less efficient cycles.

By understanding these internal mechanics, you move from simply operating a machine to mastering a critical scientific process.

Summary Table:

| Key Autoclave Stage | Purpose | Critical Factor |

|---|---|---|

| Purge (Air Removal) | Removes air to prevent cold spots and ensure steam penetration. | Complete air removal is essential for sterility. |

| Sterilization (Heat & Hold) | Maintains high temperature (e.g., 121°C) and pressure for a set time (e.g., 15-20 mins). | Sustained temperature and pressure kill all microbes, including spores. |

| Exhaust & Cooling | Safely releases pressure and cools the load, often with a drying phase. | Prevents wet packs and ensures load integrity. |

Ensure Uncompromised Sterility in Your Lab

Understanding the internal mechanics of an autoclave is the first step toward flawless sterilization. Achieving reliable, repeatable results requires equipment that is precisely engineered for performance and safety.

KINTEK is your trusted partner for laboratory autoclaves. We specialize in high-quality lab equipment designed to meet the rigorous demands of research, healthcare, and industrial applications. Our autoclaves feature robust construction, precise control systems, and critical safety mechanisms to guarantee effective sterilization cycle after cycle.

Let us help you enhance your lab's capabilities:

- Guaranteed Sterility: Our autoclaves are designed for complete air removal and uniform steam penetration.

- Operational Safety: Built-in safety features protect your personnel and valuable samples.

- Process Efficiency: Optimize your workflow with reliable and efficient sterilization cycles.

Ready to achieve perfect sterilization? Contact KINTEK today to find the ideal autoclave solution for your specific laboratory needs.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- How long does a typical autoclave run? Understand the Full Cycle for Safe Sterilization

- Why is chemical sterilization sometimes used as an alternative to autoclaving? To Safely Sterilize Heat-Sensitive Equipment

- What are the common uses of autoclave? Achieve Absolute Sterility for Safety and Precision

- What are the four applications of autoclave? Essential Sterilization for Healthcare, Labs & Industry

- What is the function of a circulating loop system with a Hastelloy autoclave? Enhance PWR Corrosion Research Accuracy

- How is an autoclave checked and maintained? A Guide to Guaranteed Sterilization

- Why is the temperature of an autoclave 121? The Science of Reliable Sterilization

- What is the usual temperature of an autoclave? Master the 121°C Standard for Effective Sterilization