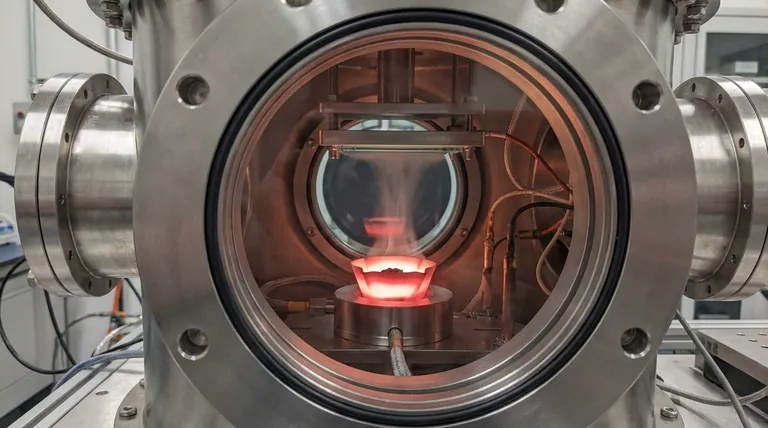

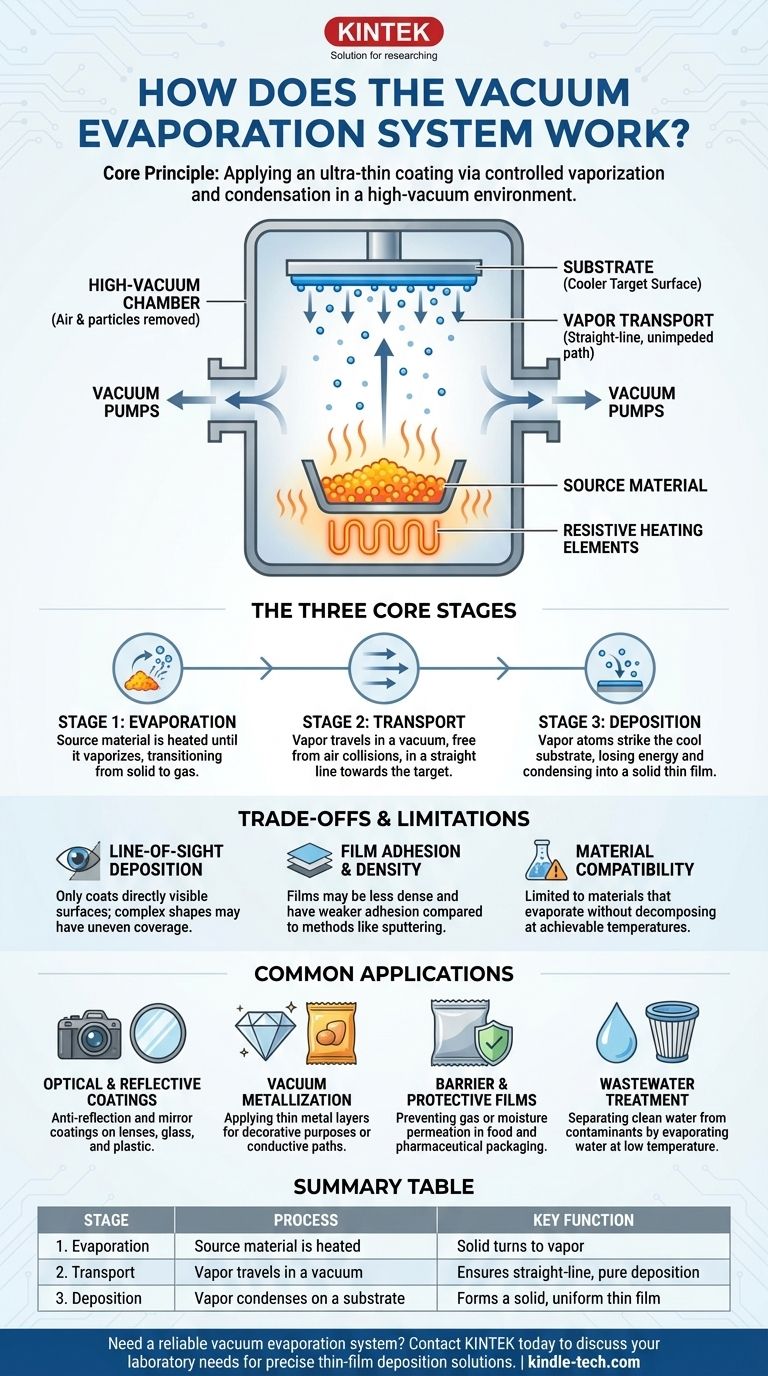

At its core, a vacuum evaporation system is a method for applying an ultra-thin coating of one material onto another. It works by heating a source material in a high-vacuum chamber until it vaporizes, allowing these vapor particles to travel unimpeded and condense onto a cooler target surface, forming a solid, uniform film.

The central principle of vacuum evaporation is not just the heating, but the vacuum itself. By removing air and other particles, the system creates a clear, straight-line path for the vaporized material to travel from the source to the substrate, ensuring a pure and direct deposition.

The Three Core Stages of Vacuum Evaporation

The entire process, though technologically complex, can be understood as a simple, three-stage physical transformation.

Stage 1: Evaporation (Solid to Vapor)

The process begins by placing the source material (e.g., a metal like aluminum or a compound like magnesium fluoride) inside the vacuum chamber. This material is then heated using methods like resistive heating, where an electrical current passes through it.

As the source material's temperature rises, it reaches a point where its atoms gain enough energy to transition directly from a solid state into a gaseous vapor.

Stage 2: Transport (The Role of the Vacuum)

This stage is what makes the technique so effective. The chamber is pumped down to a high vacuum, removing the vast majority of air molecules.

Without a vacuum, the vaporized source atoms would constantly collide with air particles, scattering in random directions, reacting with oxygen or nitrogen, and losing energy. The vacuum ensures the vapor travels in a straight, uninterrupted "line-of-sight" path toward the target.

Stage 3: Deposition (Vapor to Solid)

A target object, known as the substrate, is placed in the path of the vapor. This substrate (e.g., a lens, a silicon wafer, or a piece of plastic) is kept at a cooler temperature.

When the hot vapor atoms strike the cool substrate, they rapidly lose their thermal energy, causing them to condense back into a solid state. This condensation builds up atom by atom, forming a predictable and highly uniform thin film.

Understanding the Trade-offs and Limitations

While powerful, vacuum evaporation is not a universal solution. Understanding its inherent trade-offs is critical for proper application.

Line-of-Sight Deposition

Because the vapor travels in a straight line, the process can only coat surfaces that are directly visible to the source. Complex, three-dimensional objects with undercuts or hidden surfaces will not receive a uniform coating.

Film Adhesion and Density

Compared to other Physical Vapor Deposition (PVD) methods like sputtering, films created by thermal evaporation can sometimes be less dense and have weaker adhesion to the substrate. The deposited atoms have lower kinetic energy, leading to a less compact film structure.

Material Compatibility

The process is limited to materials that can be evaporated at temperatures that are practically achievable and that donot decompose when heated. Some alloys or compounds can be difficult to evaporate without changing their chemical composition.

Common Applications of Vacuum Evaporation

The characteristics of this process make it ideal for several specific industrial and scientific uses.

Optical and Reflective Coatings

The precise thickness control is perfect for creating anti-reflection coatings on lenses and mirror coatings on glass and plastic. This is one of its oldest and most common uses.

Vacuum Metallization

This technique is widely used to apply a thin layer of metal, often aluminum, onto polymers for decorative purposes (e.g., shiny plastic trophies, food packaging) or for creating conductive paths in electronics.

Barrier and Protective Films

Thin films deposited via vacuum evaporation can act as barriers against gas or moisture permeation, which is essential for flexible packaging for food and pharmaceuticals.

Wastewater Treatment

In a distinct application, the same principle is used to separate clean water from contaminants. Wastewater is heated under a vacuum, causing the water to evaporate at a lower temperature, leaving behind salts, oils, and other pollutants. The pure water vapor is then condensed and collected.

Is Vacuum Evaporation Right for Your Goal?

To make an effective decision, align the process capabilities with your primary objective.

- If your primary focus is cost-effective, simple coatings on flat surfaces: Vacuum evaporation is an excellent choice due to its relative simplicity, high deposition rate, and ability to create highly pure films.

- If you need highly dense, durable films on complex shapes: You should explore alternative PVD methods like sputtering, which imparts more energy to the atoms and does not have the same strict line-of-sight limitations.

- If your goal is liquid separation rather than film deposition: The wastewater treatment variant of this technology is specifically designed for this and is highly effective at purifying water from non-volatile contaminants.

Understanding this interplay of heat, vacuum, and condensation is the key to leveraging the unique capabilities of this foundational technology.

Summary Table:

| Stage | Process | Key Function |

|---|---|---|

| 1. Evaporation | Source material is heated | Solid turns to vapor |

| 2. Transport | Vapor travels in a vacuum | Ensures straight-line, pure deposition |

| 3. Deposition | Vapor condenses on a substrate | Forms a solid, uniform thin film |

Need a reliable vacuum evaporation system for your lab? KINTEK specializes in high-quality lab equipment and consumables for precise thin-film deposition. Whether you're working on optical coatings, electronics, or R&D, our solutions ensure efficiency and purity. Contact us today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the thermal evaporation method in thin film? A Guide to Simple, Cost-Effective PVD

- What are the advantages and disadvantages of e-beam evaporation? High Purity Films for Demanding Applications

- What is the impact of substrate temperature on film properties? Optimize Density, Crystallinity & Stress

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the evaporation process of semiconductors? A Guide to High-Purity Thin Film Deposition

- What are the hazards of evaporation? Avoid Process Failures and Material Contamination

- What is the process of evaporation coating? A Guide to Thin Film Deposition

- What are the factors affecting evaporation? Control the Rate of Any Liquid's Vaporization