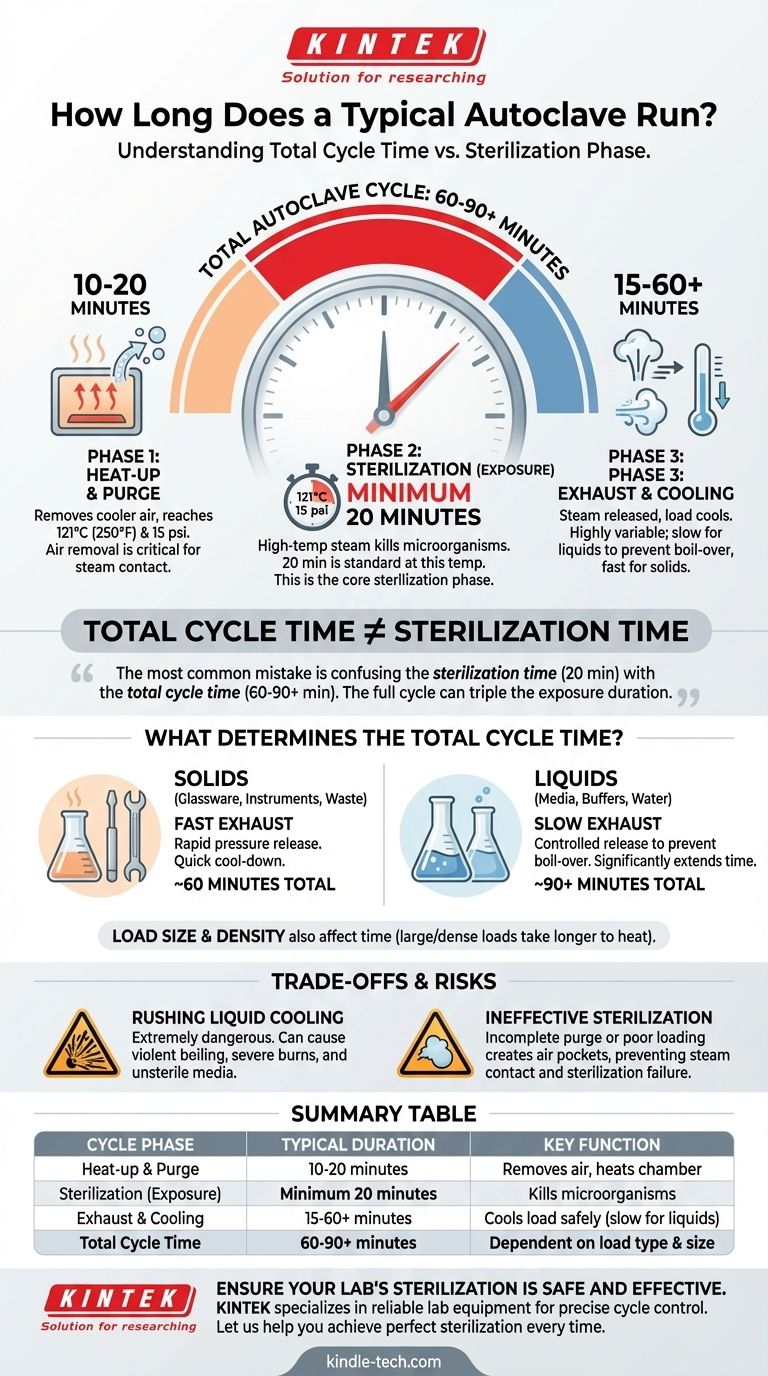

In a standard autoclave cycle, the actual sterilization phase—where microorganisms are actively killed—typically lasts for a minimum of 20 minutes at 121°C (250°F) and 15 psi of pressure. However, this is only one part of the total process. The complete autoclave run, from start to finish, often takes much longer, usually between 60 to 90 minutes or more, depending entirely on the contents being sterilized.

The most common mistake is confusing the sterilization time with the total cycle time. While the core sterilization might only be 20 minutes, the full cycle including heat-up, air purging, and crucial cool-down periods can easily triple that duration, especially when sterilizing liquids.

The Anatomy of an Autoclave Cycle

To understand the total time commitment, you must look at the entire process, which consists of several distinct phases. The 20-minute figure only refers to the exposure phase.

Phase 1: Heat-up and Purge

Before sterilization can begin, the chamber must reach the target temperature and pressure. This phase involves venting the chamber to remove cooler, ambient air and replace it with saturated steam.

Proper air removal is critical because air pockets can act as an insulating barrier, preventing steam from contacting all surfaces and leading to sterilization failure. This phase can take 10-20 minutes.

Phase 2: Sterilization (Exposure)

This is the phase people are most familiar with. Once the target temperature and pressure (e.g., 121°C and 15 psi) are reached, the timer for the sterilization period begins.

During this time, the high-temperature steam denatures the essential proteins and enzymes of microorganisms, rendering them non-viable. A 20-minute exposure is the standard for most general lab applications at this temperature.

Phase 3: Exhaust and Cooling

After the exposure time is complete, the steam must be released, and the load must cool down. This is the most variable part of the cycle and a major factor in the total run time.

The method of exhaust depends heavily on the load. This phase can last anywhere from 15 minutes to over an hour.

What Determines the Total Cycle Time?

The "typical" run is a myth; the load dictates the time. Several factors dramatically influence the overall duration of the autoclave cycle.

Load Type: Solids vs. Liquids

This is the single biggest determinant of cycle time.

Solid, dry goods (glassware, metal instruments, waste) can use a "fast exhaust," where pressure is rapidly released. Their cool-down period is relatively quick.

Liquids (culture media, buffers) require a "slow exhaust." Releasing pressure too quickly would cause the superheated liquids to boil over violently, leading to loss of volume, potential contamination, and even shattered glassware. The slow, controlled pressure release needed for liquids significantly extends the cycle time.

Load Size and Density

A large, densely packed load takes longer to heat up than a small, loosely arranged one. The steam needs more time to penetrate to the very center of the pack or the largest container.

For this reason, it's crucial not to overpack the autoclave. Leaving space between items ensures efficient steam circulation and effective sterilization.

Understanding the Trade-offs and Risks

Attempting to speed up an autoclave cycle without understanding the principles involved can lead to failed sterilization or significant safety hazards.

The Danger of Rushing the Cooling Phase

Forcing a liquid cycle to cool faster is extremely dangerous. Opening the autoclave door while the liquids are still superheated (above their boiling point at normal atmospheric pressure) can cause them to boil explosively.

This can result in severe burns, damaged equipment, and completely unsterile media. Always allow the cycle to finish completely as programmed.

Ineffective Sterilization from Air Pockets

If the purge phase is incomplete, trapped air can prevent parts of the load from reaching the required temperature. The cycle will complete, but the items will not be sterile.

This is why proper loading is just as important as setting the correct time and temperature. Ensure steam has a clear path to all surfaces.

Planning Your Autoclave Run Effectively

Use the nature of your load to estimate your time commitment and ensure a safe, successful outcome.

- If your primary focus is sterilizing solid goods (glassware, instruments, wrapped tools): You can plan for a faster overall cycle, likely around 60 minutes, as a fast exhaust and cool-down are appropriate.

- If your primary focus is sterilizing liquids (media, water, buffers): You must plan for a much longer cycle, often 90 minutes or more, to accommodate the essential slow exhaust and cooling phase.

- If your goal is absolute certainty of sterility: Use biological indicators or autoclave tape to validate that your cycle parameters and loading practices are effective for your specific load.

Understanding the full cycle—not just the 20-minute exposure time—is the key to safe, efficient, and effective sterilization.

Summary Table:

| Cycle Phase | Typical Duration | Key Function |

|---|---|---|

| Heat-up & Purge | 10-20 minutes | Removes air, heats chamber to 121°C (250°F) |

| Sterilization (Exposure) | Minimum 20 minutes | Kills microorganisms with saturated steam |

| Exhaust & Cooling | 15-60+ minutes | Cools load safely; slow for liquids, fast for solids |

| Total Cycle Time | 60-90+ minutes | Highly dependent on load type (liquids take longer) |

Ensure Your Lab's Sterilization is Safe and Effective

Planning your autoclave runs correctly is critical for both safety and experimental success. KINTEK specializes in providing reliable lab equipment and consumables, including autoclaves designed for precise cycle control and user safety.

Let us help you achieve perfect sterilization every time. Our experts can assist you in selecting the right autoclave for your specific needs, whether you primarily work with liquids, solids, or a combination.

Contact KINTEK today to discuss your laboratory's sterilization requirements and discover how our solutions can enhance your lab's efficiency and safety.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What is the primary function of a laboratory autoclave in the pre-treatment of medical plastic waste for liquid fuel?