On average, a complete autoclave cycle takes between 25 and 60 minutes. While the core sterilization phase is often set to a minimum of 15 minutes at 121°C, this is only one part of a much longer process. The total time is significantly influenced by the size and type of the load being sterilized, as it includes essential heating, pressurization, and cooling stages.

The most common point of confusion is mistaking the short "sterilization time" for the "total cycle time." The total duration is dictated by the load's characteristics, which determine how long it takes for the entire system to heat up, for steam to penetrate the material, and for the contents to cool safely.

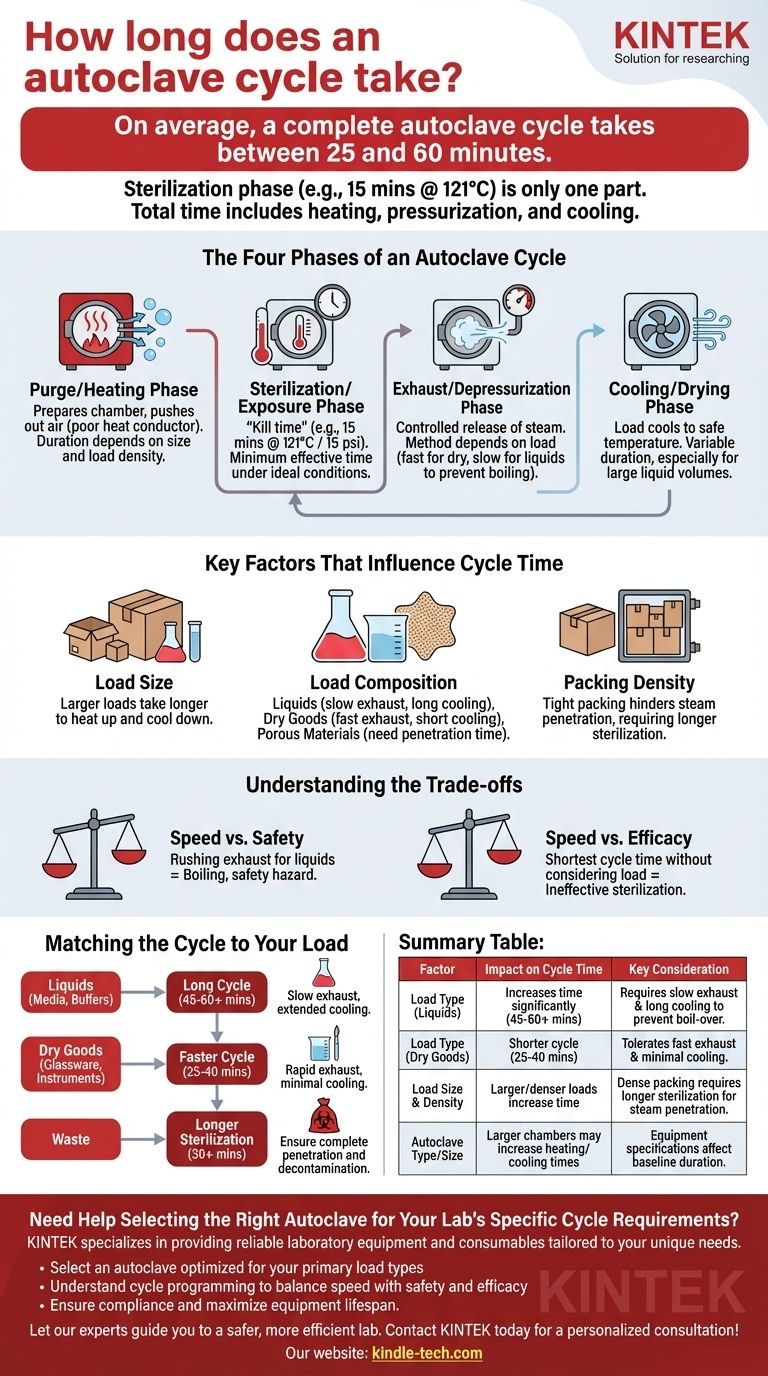

The Four Phases of an Autoclave Cycle

To understand why cycle times vary, it's essential to see the process not as a single event, but as four distinct phases. Each phase has a purpose and a variable duration.

Phase 1: Purge/Heating Phase

This initial stage prepares the chamber for sterilization. Pressurized steam is forced into the chamber, pushing out the cooler, ambient air.

This phase is critical because air is a poor conductor of heat and its presence can create cool spots, leading to sterilization failure. The duration depends heavily on the autoclave's size and the load's density.

Phase 2: Sterilization/Exposure Phase

This is the "kill time" where the actual sterilization occurs. The autoclave holds the contents at a specific temperature and pressure for a set period to destroy all microorganisms.

A standard setting for many general laboratory applications is 15 minutes at 121°C (250°F) and 15 psi. This is the number most people are familiar with, but it's the minimum effective time under ideal conditions.

Phase 3: Exhaust/Depressurization Phase

Once the sterilization time is complete, the steam must be released from the chamber. This is done in a controlled manner to bring the internal pressure back to ambient levels.

The method used here depends on the load. Dry, non-liquid loads can use a fast exhaust, while liquids require a very slow exhaust to prevent them from boiling over.

Phase 4: Cooling/Drying Phase

Finally, the load must cool down to a temperature that is safe to handle. This can be the longest and most variable part of the entire cycle, especially for large volumes of liquid. Some autoclaves have vacuum or fan systems to accelerate this phase for dry goods.

Key Factors That Influence Cycle Time

A 15-minute sterilization phase can easily become part of a 60-minute total cycle. The difference is determined by the load itself.

The Size of the Load

A larger and more substantial load will take significantly longer to heat up to the target temperature and, just as importantly, will take much longer to cool down.

The Composition of the Load

The material being sterilized is the single most important factor.

- Liquids: Require a slow exhaust and a very long cooling time. A large flask of media can add 30 minutes or more to the cooling phase alone.

- Dry Glassware/Instruments: These heat and cool relatively quickly and can tolerate a fast exhaust, resulting in the shortest cycle times.

- Porous Materials: Items like surgical gowns or animal bedding require more time for steam to fully penetrate and often need a post-sterilization drying phase.

The Density of the Packing

If items are packed too tightly, it creates a barrier to steam penetration. This can force the operator to increase the sterilization time to ensure the items in the center of the load reach the required temperature.

Understanding the Trade-offs

Optimizing for speed can introduce significant risks if not managed correctly.

Speed vs. Safety

Rushing the exhaust phase for liquids is a common mistake. The sudden drop in pressure will cause superheated liquids to boil violently, which can lead to shattered glassware, loss of media, and a significant safety hazard.

Speed vs. Efficacy

Simply choosing the shortest possible cycle time without considering the load's size and density is a recipe for failure. If the items in the center of the load never reach the target temperature for the required duration, the entire cycle is ineffective.

Matching the Cycle to Your Load

Your primary goal dictates the necessary approach to the autoclave cycle.

- If your primary focus is sterilizing liquids (e.g., media, buffers): Plan for a long cycle (45-60+ minutes) that prioritizes a slow exhaust and an extended cooling period to prevent boil-over.

- If your primary focus is sterilizing dry goods (e.g., glassware, instruments): You can use a much faster cycle (25-40 minutes) with a rapid exhaust and minimal cooling time.

- If your primary focus is sterilizing waste: Use a longer sterilization phase (30+ minutes) to ensure complete penetration and decontamination, especially with dense biohazard bags.

Ultimately, understanding the factors that influence the total cycle time is the key to ensuring both effective sterilization and safe operation.

Summary Table:

| Factor | Impact on Cycle Time | Key Consideration |

|---|---|---|

| Load Type (Liquids) | Increases time significantly (45-60+ mins) | Requires slow exhaust & long cooling to prevent boil-over |

| Load Type (Dry Goods) | Shorter cycle (25-40 mins) | Tolerates fast exhaust & minimal cooling |

| Load Size & Density | Larger/denser loads increase time | Dense packing requires longer sterilization for steam penetration |

| Autoclave Type/Size | Larger chambers may increase heating/cooling times | Equipment specifications affect baseline duration |

Need Help Selecting the Right Autoclave for Your Lab's Specific Cycle Requirements?

Choosing the correct autoclave and cycle settings is critical for effective sterilization, operational safety, and workflow efficiency. KINTEK specializes in providing reliable laboratory equipment and consumables tailored to your unique needs.

We can help you:

- Select an autoclave optimized for your primary load types (liquids, glassware, waste).

- Understand cycle programming to balance speed with safety and efficacy.

- Ensure compliance and maximize the lifespan of your equipment.

Let our experts guide you to a safer, more efficient lab. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- What are the factors for an autoclave to be effective? Master Time, Temperature, Pressure, and Steam Contact

- Is an autoclave a medical device? Understanding Regulatory Classification and Intended Use

- What are the limitations of an autoclave? Understanding Material Compatibility and Safety Constraints

- What industries use autoclaves? From Healthcare to Manufacturing

- Why is it important to use the autoclave to sterilize laboratory tools? Ensure Complete Sterility for Reliable Results

- What function does a PTFE-lined autoclave serve for ZnS nanopowder? Achieve Pure, High-Performance Synthesis

- What is the time required for autoclaving at 121 C? A Guide to Sterilization Cycles

- What experimental environment do high-temperature and high-pressure autoclaves provide for biofuel research?