A standard autoclave sterilization cycle typically requires an exposure time of 15 to 20 minutes at 121°C (250°F) and 15 psi of pressure. However, this is only the sterilization phase itself. The total time from start to finish is often much longer, as it must also include the time required for the machine to heat up and for the specific items inside to cool down.

The machine's timer does not guarantee sterilization. The true duration depends on the temperature, pressure, and most importantly, the size, type, and density of the load, which dictates how long it takes for sterilizing steam to fully penetrate the material.

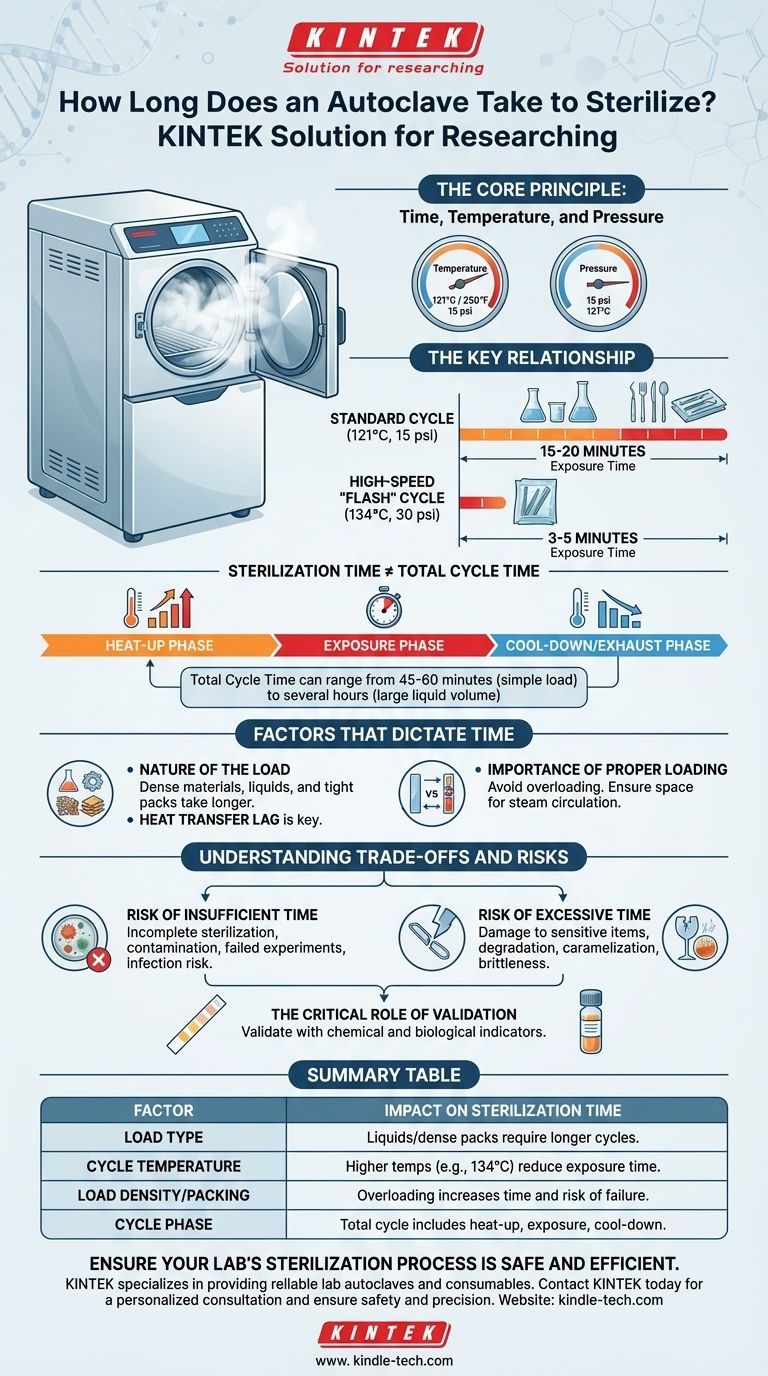

The Core Principle: Time, Temperature, and Pressure

An autoclave does not sterilize with dry heat; it uses high-pressure saturated steam. This combination is what allows it to effectively kill all microbial life, including resilient spores.

The Key Relationship

Temperature and pressure are directly linked to the required exposure time. Higher temperatures, achieved with higher pressure, can sterilize more quickly.

For example, a standard cycle runs at 121°C (15 psi), which typically requires 15-20 minutes of exposure. A high-speed "flash" cycle might run at 134°C (30 psi), reducing the necessary exposure time to as little as 3-5 minutes.

Exposure Time vs. Total Cycle Time

The "sterilization time" refers only to the exposure phase—the period when the contents of the autoclave are held at the target temperature.

The total process time includes the heat-up phase, the exposure phase, and the cool-down/exhaust phase. A complete cycle for a simple load can take 45-60 minutes, while a cycle for a large volume of liquid might take several hours.

Factors That Dictate Sterilization Time

The number on the autoclave's display is a starting point. The actual time required for effective sterilization depends entirely on the contents.

The Nature of the Load

The single most important factor is the load itself. Steam must make direct contact with every surface to be sterilized.

Dense materials, large liquid volumes, or tightly wrapped instrument packs take much longer to heat. The cycle's exposure timer does not begin until the center of the load reaches the target temperature, a delay known as heat transfer lag.

The Importance of Proper Loading

Overloading the autoclave or packing items too tightly prevents steam from circulating freely. This creates cool spots within the chamber where sterilization will fail, no matter how long the cycle runs.

Always leave space between items to ensure steam can penetrate the entire load effectively.

Understanding the Trade-offs and Risks

Choosing the wrong cycle time is not a neutral act; it has direct consequences for safety and material integrity.

The Risk of Insufficient Time

This is the most critical risk. If the exposure time is too short or steam penetration is incomplete, the load will not be sterile. This can lead to contamination, failed experiments, or in a clinical setting, dangerous infections.

The Risk of Excessive Time

Longer is not always better. Over-sterilizing can damage sensitive items. For example, laboratory growth media can degrade, sugars can caramelize, and certain plastics or rubber components can become brittle or melt if exposed to excessive heat for too long.

The Critical Role of Validation

Standard times are guidelines. For any critical application, you must validate your specific load and cycle. This is often done using chemical indicator strips or, for the highest level of assurance, biological indicators containing heat-resistant spores to prove the cycle was lethal.

Making the Right Choice for Your Goal

To ensure effective sterilization, you must match your autoclave cycle to the specific load you are processing.

- If your primary focus is standard glassware or unwrapped metal instruments: A 15-20 minute cycle at 121°C is a reliable and universally accepted baseline.

- If your primary focus is sterilizing liquids like media or buffers: You must increase the total cycle time to account for the slow heating of the liquid, with the time depending directly on the volume.

- If your primary focus is porous materials or wrapped surgical kits: You must use a cycle that includes a vacuum phase (if available) to ensure steam fully penetrates the pack.

- If your primary focus is absolute sterility for critical applications: You must validate your specific load configuration with chemical and biological indicators to prove the cycle is effective.

By understanding these core principles, you move from simply running a machine to truly mastering the sterilization process.

Summary Table:

| Factor | Impact on Sterilization Time |

|---|---|

| Load Type | Liquids and dense packs require significantly longer cycles than simple glassware. |

| Cycle Temperature | Higher temperatures (e.g., 134°C) reduce exposure time to 3-5 minutes. |

| Load Density/Packing | Overloading or tight packing prevents steam penetration, increasing time and risk of failure. |

| Cycle Phase | Total cycle time includes heat-up, exposure (15-20 min at 121°C), and cool-down phases. |

Ensure your lab's sterilization process is both safe and efficient.

Choosing the right autoclave and cycle is critical for protecting your experiments, samples, and personnel. KINTEK specializes in providing reliable lab autoclaves and consumables tailored to your specific needs, whether you're processing delicate media, surgical instruments, or standard glassware.

Our experts can help you select and validate the perfect equipment to achieve guaranteed sterility without compromising your materials.

Contact KINTEK today for a personalized consultation and ensure your lab's foundation is built on safety and precision.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why use PPL-Lined Autoclaves for Vanadium Dioxide Nanorods? Achieve Pure Crystallization at 280°C

- What precautions should be taken during autoclave in microbiology? Essential Safety Steps for Sterilization Success

- Why is a Teflon-lined high-pressure autoclave required for Mo-Ti-N catalyst synthesis? Ensure Purity and Precision

- What is the most efficient method of sterilization? Match the Right Method to Your Materials

- What are the three advantages of the steam autoclave? Unmatched Speed, Cost-Effectiveness & Safety

- How should solid materials in bags be prepared for decontamination? Master Steam Penetration for Safe Sterilization

- Is autoclave the same as sterilization? Unlocking the Key Differences for Lab Safety

- What role does a high-pressure hydrothermal autoclave play in 3D-GO synthesis? Optimize Your Graphene Composites