A standard autoclave sterilization cycle typically lasts between 30 and 60 minutes. However, this is not a fixed time. The precise duration is dictated by the specific contents being sterilized, including their size, density, and whether they are solid instruments or liquids.

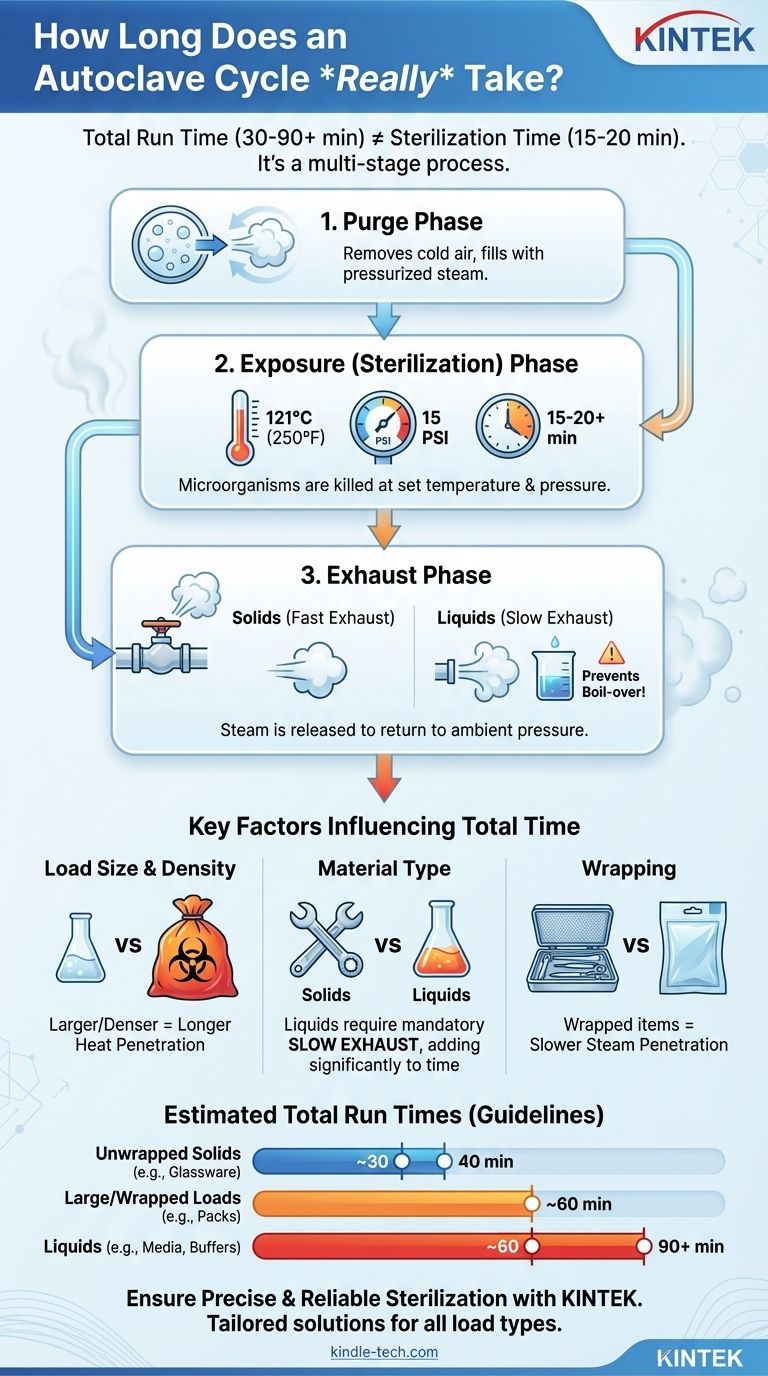

The total run time of an autoclave is much longer than the 15-20 minute sterilization exposure time you often hear about. A complete cycle includes critical air purge and steam exhaust phases, and its final duration is primarily determined by the size, density, and wrapping of the items inside.

The Anatomy of a Sterilization Cycle

To understand the total time, you must understand that an autoclave cycle is a multi-stage process. The "sterilization time" is just one part of the total run time.

Phase 1: The Purge Phase

Before sterilization can begin, all air must be removed from the chamber. Air pockets act as insulators and prevent steam from reaching all surfaces, which would lead to a sterilization failure.

In this phase, steam is injected into the chamber to displace the cooler, denser air, which is then forced out through a vent. This continues until the chamber is filled only with pressurized, saturated steam.

Phase 2: The Exposure (Sterilization) Phase

This is the phase where the actual killing of microorganisms occurs. The load is held at a specific temperature and pressure for a set duration.

The most common standard for sterilization is maintaining a temperature of 121°C (250°F) under approximately 15 PSI of pressure. The minimum exposure time at this temperature is typically 15-20 minutes, but it is often longer for larger loads.

Phase 3: The Exhaust Phase

Once the exposure time is complete, the steam must be released from the chamber so the pressure can return to ambient levels and the door can be opened.

The speed of this phase is critical. For solid goods like instruments and glassware, a fast exhaust is used. For liquids, a very slow exhaust is mandatory to prevent the liquids from boiling over violently inside their containers.

Why Cycle Time Varies: Key Influencing Factors

The "30 to 60 minute" answer is a general guideline. The actual time your specific load requires will vary based on several critical factors.

Load Size and Density

A small, loosely packed load of instruments will heat up quickly and allow for rapid steam penetration. In contrast, a large, dense biohazard bag or a tightly packed tray of equipment will require a much longer cycle for heat to reach the center of the load.

Type of Material (Liquids vs. Solids)

This is one of the most significant factors. Sterilizing liquids takes much longer than sterilizing solid instruments, not because of the exposure time, but because of the slow exhaust phase. A cycle for a flask of media can easily take over an hour to prevent boil-over, while a cycle for empty glassware might be done in 30 minutes.

Wrapping and Containment

Items that are wrapped in sterilization pouches or cloth require more time. The steam must first penetrate the outer wrapping before it can reach and sterilize the surfaces of the instrument inside, adding to the overall cycle time.

Understanding the Trade-offs

Choosing a cycle duration is a balance between ensuring sterility and preserving the integrity of the materials.

The Risk of Rushing a Cycle

Shortening a cycle to save time is extremely risky. Incomplete air purging can leave cold spots, and insufficient exposure time may fail to kill resistant bacterial spores. The result is a non-sterile load, which completely defeats the purpose of autoclaving.

The Downside of Overprocessing

While ensuring sterility is paramount, excessively long cycles are also undesirable. Prolonged exposure to high heat and steam can degrade certain plastics, dull sharp instruments, and break down chemical components in laboratory media. It also wastes energy and valuable time.

The Liquid Cycle Dilemma

The need for a slow, careful exhaust phase for liquids represents a fundamental trade-off. Rushing this phase can cause glass vessels to crack from thermal shock or stoppers to fly off as the superheated liquid boils over, creating a safety hazard and a mess. The price for safety and integrity is a significantly longer total cycle time.

Making the Right Choice for Your Load

Use the following guidelines to estimate your autoclave run times. Always defer to your institution's specific protocols and the manufacturer's recommendations.

- If your primary focus is hard, unwrapped goods (glassware, metal tools): A cycle with a 20-minute exposure time and fast exhaust may be complete in 30-40 minutes.

- If your primary focus is liquids (media, buffers): Plan for a significantly longer cycle. Even with a 20-minute exposure time, the slow exhaust will extend the total run time to 60-90 minutes or more.

- If your primary focus is large or wrapped loads (waste bags, surgical packs): You must increase the exposure time to 30 minutes or longer to ensure full steam penetration, pushing the total cycle time toward 60 minutes.

Ultimately, effective sterilization depends on understanding that the autoclave's timer is a tool to be set based on the principles of heat, steam, and the specific challenge of your load.

Summary Table:

| Factor | Impact on Cycle Time |

|---|---|

| Load Type (Liquids vs. Solids) | Liquids require a slow exhaust, adding 30+ minutes. Solids can use a fast exhaust. |

| Load Size & Density | Large, dense loads (e.g., biohazard bags) need longer exposure times for steam penetration. |

| Wrapping/Packaging | Wrapped items require extra time for steam to penetrate the packaging material. |

| Standard Cycle (Solids) | ~30-60 minutes total (includes purge, 15-20 min exposure, and exhaust). |

| Liquid Cycle | ~60-90+ minutes total (due to mandatory slow exhaust phase). |

Ensure Precise and Reliable Sterilization in Your Lab

Choosing the right autoclave and cycle is critical for both safety and efficiency. Improper cycles can lead to non-sterile loads or damaged equipment.

KINTEK provides the solutions you need. We specialize in high-performance autoclaves and expert support for laboratories. Our equipment ensures consistent, reliable sterilization cycles tailored to your specific materials—whether you're processing delicate liquids, wrapped instruments, or large-volume waste.

Let us help you achieve perfect results every time.

Contact KINTEK today to discuss your lab's sterilization requirements and find the ideal autoclave solution.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- Is autoclaving used to sterilize liquids? The Definitive Guide to Safe and Effective Sterilization

- What is the standard time for sterilization? Optimize Your Process for Safety and Efficiency

- What function does a high-pressure laboratory autoclave serve in walnut shell pretreatment? Enhance Biomass Reactivity.

- What is the primary role of high-pressure high-temperature autoclaves in SCWR research? Key Roles in Material Validation

- What is the temperature above 100 for autoclaving? Achieve Sterilization at 121°C

- What are the limitations of an autoclave? Understanding Material Compatibility and Safety Constraints

- How do you clean an autoclave in a lab? Ensure Sterilization Efficacy & Extend Equipment Life

- Which autoclave is used in microbiology lab? Gravity Displacement vs. Pre-Vacuum Explained