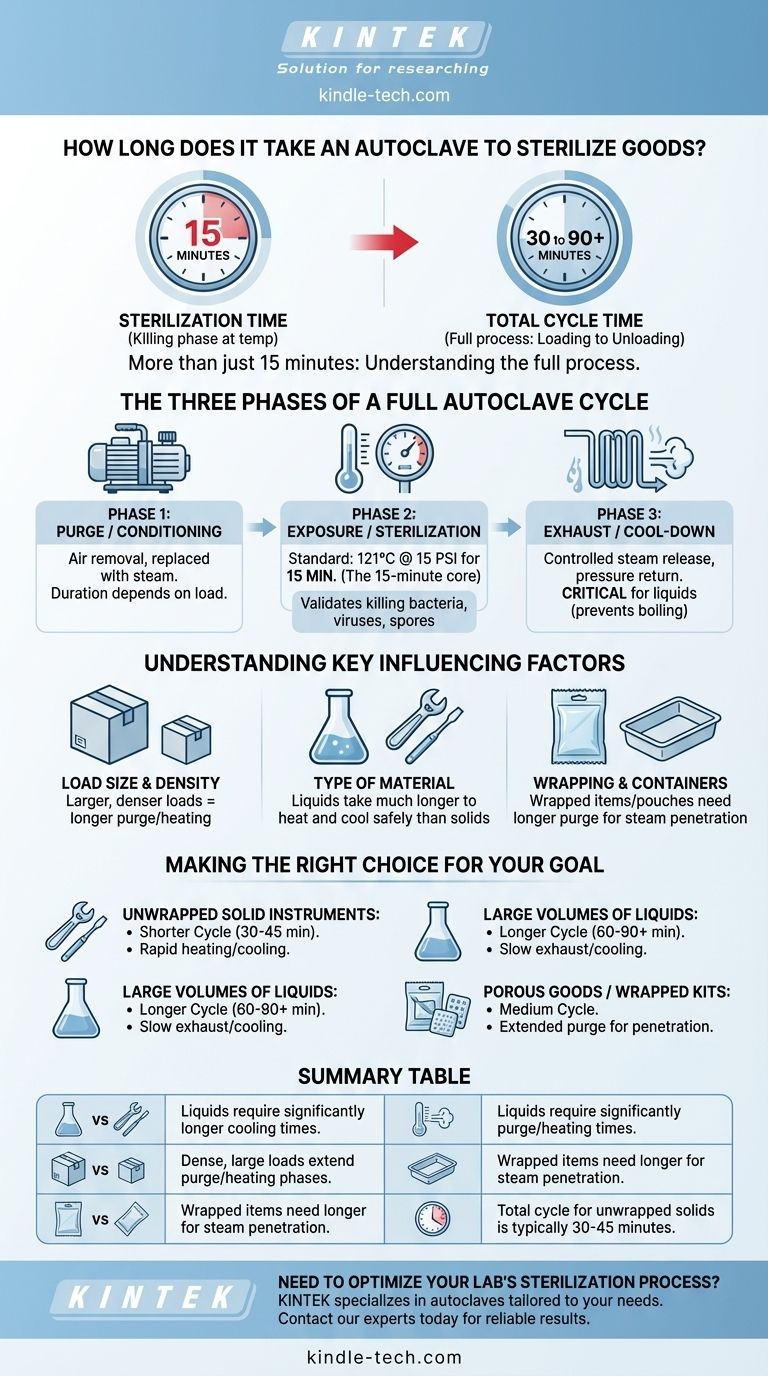

While the core sterilization phase is often cited as 15 minutes, this is only one part of a much longer process. The total time required for an autoclave to fully process a load from start to finish is significantly greater, typically ranging from 30 to 90 minutes or more depending on several critical factors.

The key distinction to understand is between sterilization time (the specific period where killing occurs at temperature) and total cycle time (the entire process from loading to unloading). Focusing only on the 15-minute sterilization window is a common oversimplification that ignores the crucial phases before and after it.

The Three Phases of a Full Autoclave Cycle

An autoclave cycle is not a single event but a sequence of three distinct phases. The duration of each phase contributes to the total run time.

Phase 1: The Purge (or Conditioning) Phase

Before sterilization can begin, all air must be removed from the chamber and the load itself. Air acts as an insulator and prevents steam from making direct contact with the surfaces of the items, which would lead to a failed cycle.

This phase involves replacing the trapped air with saturated steam. The time required depends heavily on the type and density of the load being sterilized.

Phase 2: The Exposure (or Sterilization) Phase

This is the phase people most commonly refer to. Once the chamber reaches the target temperature and pressure, the clock for the exposure phase begins.

The standard for many applications is maintaining a temperature of 121°C (250°F) at 15 PSI for a minimum of 15 minutes. This is the scientifically validated time required to kill bacteria, viruses, and heat-resistant spores under these conditions.

Phase 3: The Exhaust (or Cool-down) Phase

After the exposure phase is complete, the steam is released from the chamber, and the pressure is slowly returned to ambient levels. This phase is critical for safety and can be one of the longest parts of the cycle.

Liquids, in particular, must be cooled down slowly to prevent them from boiling over. This slow and controlled pressure release can add significant time to the total cycle.

Understanding the Key Influencing Factors

The idea of a single, fixed cycle time is a myth. The actual duration is a variable determined by the nature of what you are sterilizing.

Load Size and Density

A large, densely packed load takes much longer to heat than a small, sparse one. The "purge" phase will be extended to ensure steam penetrates every part of the load, and the "exposure" timer only begins once the entire load reaches the target temperature.

Type of Material

Different materials have different thermal properties. Sterilizing a large flask of liquid media will take far longer than sterilizing a tray of unwrapped metal instruments due to the time required to heat and, more importantly, safely cool the liquid.

Wrapping and Containers

Items placed in sterilization pouches or wrapped in drapes require longer purge times to ensure steam can displace the air within the packaging. The type of container (e.g., sealed vs. vented) also dramatically impacts the cycle parameters.

Making the Right Choice for Your Goal

To properly estimate your cycle time, you must consider the load, not just the machine's settings.

- If your primary focus is sterilizing unwrapped, solid instruments: Your total cycle time will be on the shorter end, likely in the 30-45 minute range, as heating and cooling are rapid.

- If your primary focus is sterilizing large volumes of liquids (e.g., media): Plan for a much longer cycle, often 60-90 minutes or more, as the majority of the time will be dedicated to the slow exhaust and cooling phase.

- If your primary focus is sterilizing porous goods or wrapped kits: Expect a longer purge phase to ensure complete steam penetration, placing your total cycle time between that of solid instruments and liquids.

Ultimately, effective sterilization is defined by process validation and safety, not by speed.

Summary Table:

| Factor | Impact on Cycle Time |

|---|---|

| Load Type (Liquids vs. Solids) | Liquids require much longer cooling times, adding significant minutes. |

| Load Size & Density | Dense, large loads extend the purge and heating phases. |

| Packaging (Wrapped vs. Unwrapped) | Wrapped items need longer for steam penetration. |

| Standard Cycle (Unwrapped Solids) | Total cycle time is typically 30-45 minutes. |

Need to Optimize Your Lab's Sterilization Process?

Choosing the right autoclave is critical for efficiency and safety. KINTEK specializes in lab equipment and consumables, providing autoclaves tailored to your specific needs—whether for liquids, wrapped kits, or solid instruments.

Contact our experts today to discuss your application and ensure your lab achieves fast, reliable, and validated sterilization results.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why is autoclave done for 15 minutes? The Science Behind Sterilization Cycles

- What are the guidelines for loading an autoclave? Ensure Sterilization Success & Safety

- For what purpose are high-pressure autoclaves used in the synthesis of additives for composite polymer electrolytes?

- Why are hydrothermal synthesis autoclaves used for mesoporous HA catalysts? Engineering Superior Catalytic Efficiency

- What is the function of Refreshed Autoclaves in nuclear corrosion simulation? Ensure Data Integrity & Real-World Fidelity

- What is the safety wall in an autoclave? The Jacketed Chamber Explained for Secure Sterilization

- Why are autoclaves utilized for the hydrothermal synthesis of core-shell PCMs? Achieving Superior Shell Integrity

- What is the use of autoclave in research? Ensure Sterile Conditions for Valid Scientific Results