Determining the correct autoclave time for solids is a critical question where a simple answer can be dangerously misleading. While a common starting point for a standard load of solid lab waste is a 60-minute cycle at 121°C, this is not a universal rule. The actual time required depends entirely on the size, density, and packaging of the items being sterilized, as the primary challenge is ensuring heat penetrates to the very core of the load.

The question isn't just "how long," but "how long does it take for the center of my specific solid item to reach 121°C and hold for at least 15-20 minutes?" Total cycle time is dominated by this heat penetration phase, which varies dramatically from one load to another.

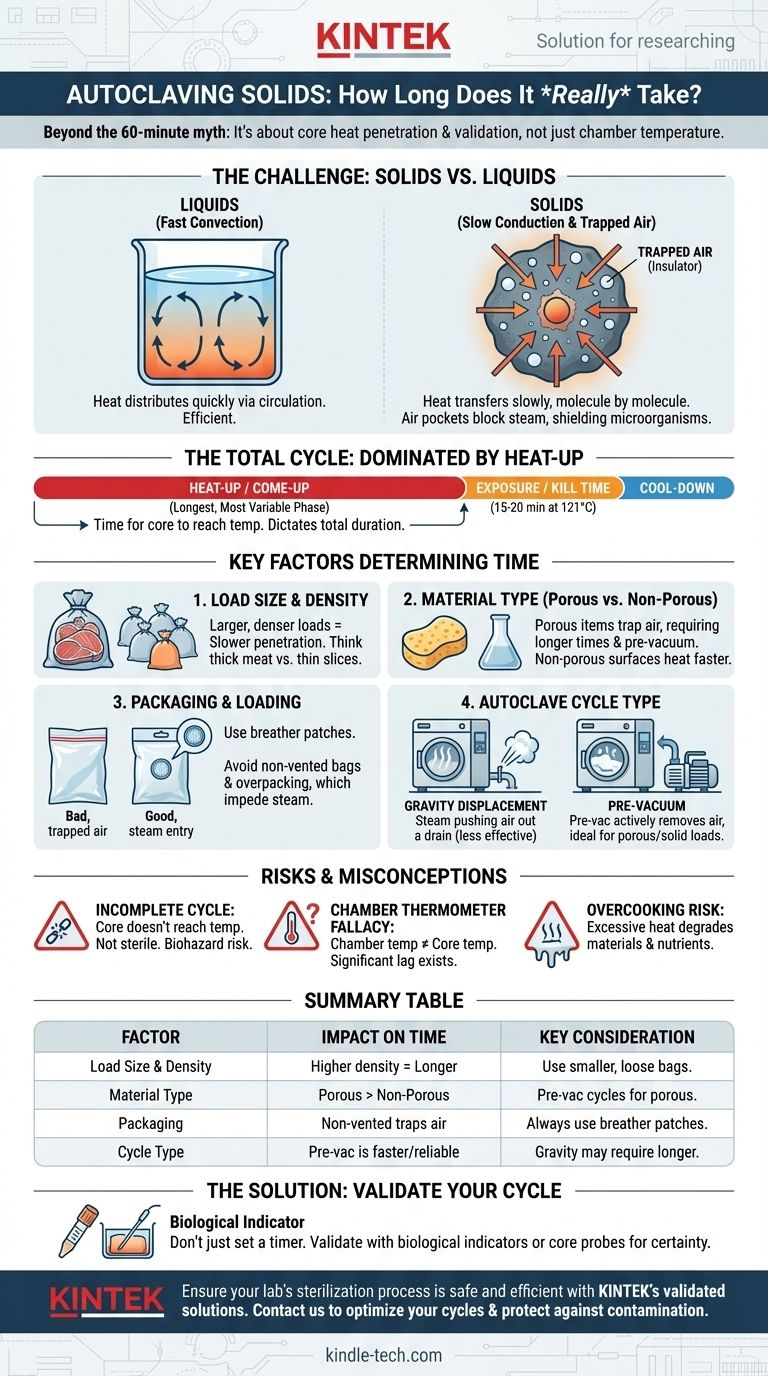

Why Solids Present a Unique Sterilization Challenge

Understanding the physics of heat transfer is key to understanding why solids require such careful consideration compared to liquids.

The Hurdle of Heat Conduction

In a liquid, heat is transferred efficiently through convection. The heated liquid circulates, rapidly distributing thermal energy throughout the container.

Solids, however, are heated by conduction. Heat must slowly transfer from the outer surface of the object, molecule by molecule, toward the center. This is a much slower and less efficient process.

The Insulating Effect of Trapped Air

Air is a poor conductor of heat and the primary enemy of steam sterilization. If air is trapped within a porous material (like bedding) or inside a poorly sealed bag, it creates insulating pockets.

These air pockets prevent sterilizing steam from making direct contact with the surfaces, effectively shielding any microorganisms within from the lethal temperature.

Defining the Total Cycle Time

An autoclave cycle consists of three main phases:

- Heat-up / Come-up Time: The time it takes for the load's core to reach the sterilization temperature (e.g., 121°C). This is the longest and most variable phase for solids.

- Exposure / Kill Time: The actual sterilization period where the entire load is held at the target temperature (typically 15-20 minutes).

- Cool-down Time: The period where the chamber is depressurized and the load cools.

For solids, the total time is almost entirely dictated by the long and unpredictable "come-up time."

Key Factors That Determine Sterilization Time

You cannot use a one-size-fits-all approach. You must evaluate the following factors for every load.

Load Size and Density

A larger and denser load presents a greater challenge for heat penetration. A single, large bag of biohazard waste will take significantly longer to sterilize than several smaller, loosely packed bags containing the same total volume.

Think of it like cooking: a very thick piece of meat takes much longer to cook through to the center than several thin pieces.

Material Type (Porous vs. Non-Porous)

Non-porous items like glassware and metal instruments sterilize relatively quickly, as steam only needs to heat the surface. The main factor here is ensuring steam can reach all surfaces.

Porous items like animal bedding, surgical drapes, or even dense plastic waste are much more difficult. They tend to trap large amounts of air, requiring specific cycles (like pre-vacuum) and longer times to ensure steam penetration.

Packaging and Loading

How items are packaged is critical. Using a standard, non-vented plastic bag will trap air and almost guarantee a failed cycle.

Always use bags specifically designed for autoclaving, which have a "breather patch" that allows air to escape and steam to enter. Furthermore, avoid stacking items or packing the chamber too tightly, as this impedes steam circulation.

Autoclave Cycle Type

Gravity Displacement cycles rely on steam being pumped into the chamber to push the cooler, denser air out through a drain. This can be less effective for complex or porous solid loads where air gets trapped.

Pre-Vacuum (Pre-vac) cycles use a vacuum pump to actively remove air from the chamber before introducing steam. This is far more effective for solids, waste bags, and porous materials, leading to more reliable sterilization and often shorter cycle times.

Understanding the Trade-offs and Risks

Simply setting a long cycle time "to be safe" is not always the best or safest strategy.

The Danger of an Incomplete Cycle

This is the most significant risk. If the cycle is too short, the core of the load never reaches sterilization temperature. The autoclave run will appear successful, but the items will not be sterile, leading to potential contamination, failed experiments, or exposure to biohazards.

The Fallacy of the Chamber Thermometer

A common and critical mistake is to assume the load is at temperature just because the autoclave's chamber thermometer reads 121°C. For any significant solid load, there is a substantial temperature lag between the chamber and the center of the items.

The Risk of "Overcooking"

While under-processing is a sterility risk, over-processing can also be a problem. Excessive heat and time can degrade certain plastics, causing them to melt or become brittle. It can also break down nutrients in any sterilized growth media that might be included in the load.

How to Determine the Right Cycle for Your Solids

Validating your specific load is the only way to guarantee sterility and optimize your process.

- If your primary focus is non-porous hard goods (e.g., glassware, metal tools): A 30-minute exposure time at 121°C is a common starting point, but ensure items are arranged to allow free steam circulation.

- If your primary focus is porous loads or waste (e.g., biohazard bags, animal bedding): Start with a 60-90 minute cycle at 121°C, and strongly consider using an autoclave with a pre-vacuum cycle for reliable air removal.

- If your primary focus is absolute certainty for critical materials: You must validate your cycle using a biological indicator or a remote thermocouple probe placed in the geometric center of the most challenging item in your load.

Successful autoclaving is a process of validation, not just a matter of setting a timer.

Summary Table:

| Factor | Impact on Sterilization Time | Key Consideration |

|---|---|---|

| Load Size & Density | Higher density = Longer time | Use smaller, loosely packed bags for efficiency |

| Material Type | Porous items (e.g., bedding) take longer than non-porous (e.g., glass) | Pre-vacuum cycles recommended for porous loads |

| Packaging | Non-vented bags trap air, increasing risk | Always use autoclave bags with breather patches |

| Cycle Type | Pre-vacuum cycles are faster and more reliable for solids | Gravity displacement may require longer times |

Ensure your lab's sterilization process is safe and efficient. KINTEK specializes in providing reliable lab equipment and consumables, including autoclaves and validated sterilization solutions tailored to your specific solid waste and material needs.

Contact us today to optimize your autoclaving cycles and protect your lab from contamination risks. Get in touch with our experts to discuss your requirements!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What factors may result in sterilization failure when using an autoclave? Prevent Failed Cycles with Expert Tips

- What types of instruments Cannot be autoclaved? Protect Your Lab Equipment from Damage

- How long does it take to vent an autoclave? A Guide to Safe and Efficient Sterilization Cycles

- Why are stainless steel autoclaves essential for LDH synthesis? Optimize 2D Nanomaterial Crystallinity

- What are the settings for autoclave sterilization? Ensure Reliable Sterility with Proper Parameters

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- What conditions do stainless steel autoclaves provide for reactor simulation? Expert Material Testing Solutions

- What damage is caused by autoclave? Protect Your Lab Equipment from Heat and Steam Damage