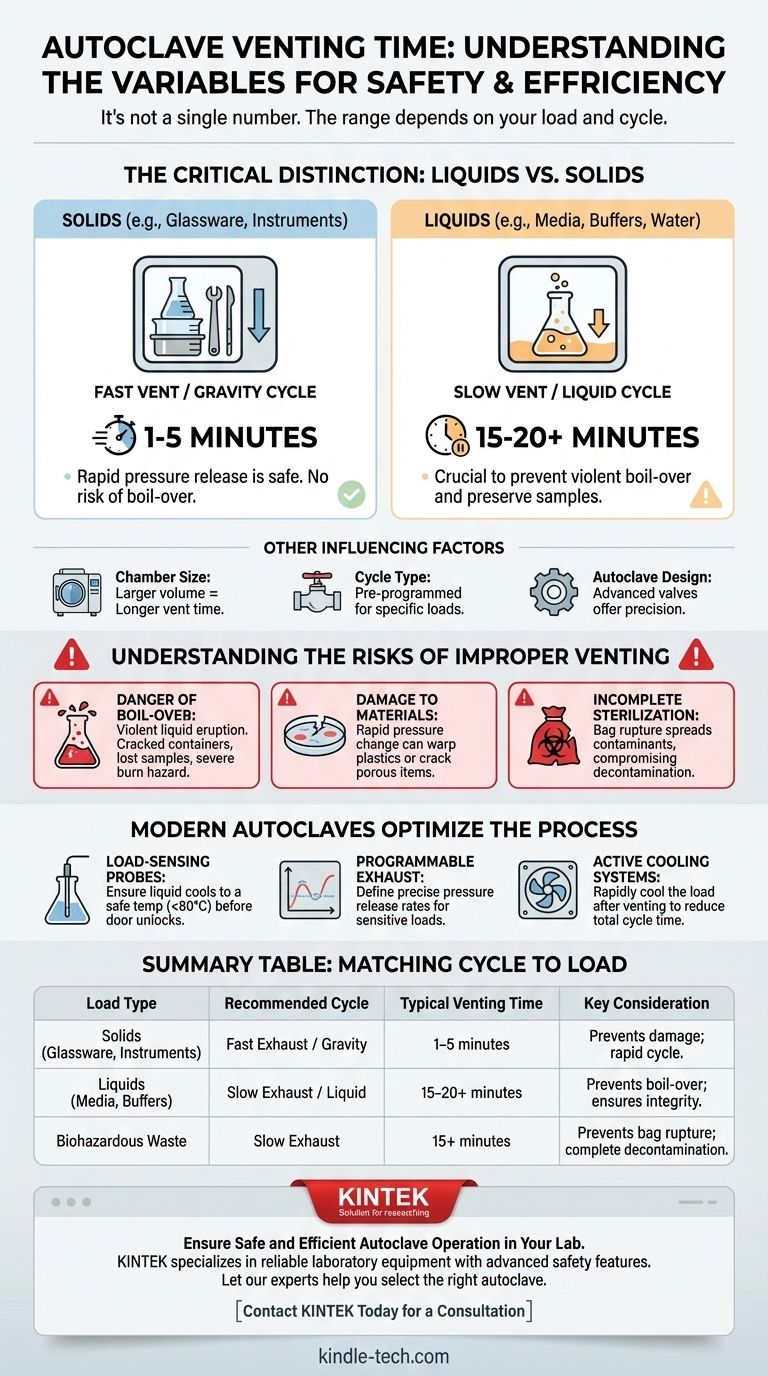

The time it takes to vent an autoclave is not a single number. It can range from as little as one to five minutes for dry goods to over 20 minutes for large liquid loads. The duration is almost entirely dependent on the type of material being sterilized and the specific autoclave cycle selected to ensure safety and prevent damage.

The most critical factor determining autoclave venting time is the nature of the load itself. A fast vent is suitable for solid, non-porous items, while a slow, controlled vent is absolutely essential for liquids to prevent violent boil-over, which can destroy samples and create a severe safety hazard.

Why Venting Time Varies So Dramatically

The venting, or exhaust, phase of an autoclave cycle is when the chamber is returned from high pressure to normal atmospheric pressure. The speed at which this happens is a controlled process, not an arbitrary one, and choosing the wrong speed has significant consequences.

The Critical Distinction: Liquids vs. Solids

The physical state of your load is the primary variable.

For solids like glassware, instruments, and utensils, pressure can be released very quickly. These items are not at risk of boiling, so a fast vent or "gravity" cycle is used to save time.

For liquids like media, buffers, or water, the situation is completely different. Under pressure, the liquid is heated well above its normal 100°C (212°F) boiling point without actually boiling. This is a superheated state.

If pressure is released too quickly, this stored energy causes the liquid to boil violently and erupt from its container. This is called boil-over. A slow vent is therefore mandatory for all liquid loads.

How Autoclave Design Influences Timing

The size of the autoclave chamber and the design of its exhaust valves also play a role.

A larger chamber contains a greater volume of steam and will naturally take longer to depressurize than a small benchtop unit, even on a "fast" setting. Modern autoclaves often have sophisticated valves that allow for precise, programmable control over the venting rate.

Programmed Cycle Types

Your autoclave will have pre-set cycles designed for different loads, which automatically control the vent speed.

- Fast Exhaust / Gravity Cycle: Designed for solids. The exhaust valve opens fully to vent steam and pressure as quickly as possible.

- Slow Exhaust / Liquid Cycle: Designed for liquids. The exhaust valve opens intermittently or very slightly to release pressure gradually, preventing boil-over.

Understanding the Risks of Improper Venting

Choosing the wrong cycle is one of the most common and dangerous mistakes in autoclave operation. The consequences range from inconvenient to hazardous.

The Danger of Boil-Over

Venting a liquid load on a fast cycle is extremely dangerous. The resulting boil-over can crack glass containers, clog the autoclave's drain filter, and cause a significant loss of your media or sample.

Most importantly, it creates a severe burn and scalding hazard for anyone who opens the door, as superheated liquid and steam can be ejected from the chamber.

Damage to Materials

Even for some solid goods, a vent that is too rapid can cause damage. The sudden change in temperature and pressure can cause some plastics to warp or crack. Porous materials may also require a slower vent to allow trapped steam to escape safely.

Incomplete Sterilization or Sealing

For items like bagged waste, a vent that is too fast can cause the bag to rupture. This can spread contaminants inside the chamber and compromise the decontamination process.

How Modern Autoclaves Optimize the Process

Modern autoclaves incorporate features that provide greater control and safety during the venting and cool-down phases, moving beyond simple fast or slow options.

Load-Sensing Temperature Probes

Advanced autoclaves use a secondary temperature probe placed directly inside a reference container within the liquid load. The autoclave's controller uses this real-world data to ensure the liquids have cooled to a safe temperature (typically below 80°C) before allowing the door to be unlocked. This is a critical safety feature.

Programmable Exhaust Rates

Many units allow operators to define a precise rate of pressure release, often called a "linear" or "controlled" exhaust. This provides fine-tuned control for particularly sensitive or large-volume liquid loads, ensuring the slowest, safest depressurization possible.

Active Cooling Systems

To reduce total cycle time without compromising safety, some autoclaves use cooling fans or water jackets around the chamber. These systems activate after the initial slow venting to rapidly cool the load down, allowing you to retrieve your materials sooner.

Matching the Vent Cycle to Your Load

Your choice must always be dictated by the contents of the autoclave chamber. There is no room for compromise when it comes to safety.

- If your primary focus is sterilizing glassware, instruments, or other dry hard goods: Use a "Fast Exhaust" or "Gravity" cycle. Venting will be rapid, often taking only a few minutes.

- If your primary focus is sterilizing liquids (media, buffers, water): You must use a "Slow Exhaust" or "Liquid" cycle. Expect this phase to take 15 minutes or longer, and never attempt to bypass safety interlocks.

- If your primary focus is decontaminating biohazardous waste: A slow exhaust is the safest option to prevent bags from bursting and to manage any liquids present in the waste.

Selecting the correct vent profile is the most critical decision for ensuring both the safety of the operator and the integrity of the sterilized load.

Summary Table:

| Load Type | Recommended Cycle | Typical Venting Time | Key Consideration |

|---|---|---|---|

| Solids (Glassware, Instruments) | Fast Exhaust / Gravity | 1 - 5 minutes | Prevents damage to materials; rapid cycle. |

| Liquids (Media, Buffers) | Slow Exhaust / Liquid | 15 - 20+ minutes | Prevents dangerous boil-over; ensures sample integrity. |

| Biohazardous Waste | Slow Exhaust | 15+ minutes | Prevents bag rupture and ensures complete decontamination. |

Ensure Safe and Efficient Autoclave Operation in Your Lab

Choosing the correct venting cycle is critical for operator safety and sample integrity. The consequences of an incorrect setting range from damaged materials to serious safety hazards.

KINTEK specializes in laboratory equipment and consumables, providing reliable autoclaves with advanced safety features like load-sensing probes and programmable exhaust rates. Our equipment is designed to handle the precise needs of your laboratory, ensuring efficient sterilization for everything from delicate liquid media to standard glassware.

Let our experts help you select the right autoclave for your specific applications. We can guide you to a solution that maximizes safety and throughput in your workflow.

Contact KINTEL today for a consultation and ensure your lab's sterilization processes are both safe and effective.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- How long does it take for the autoclave to complete its cycle? From 30 Minutes to Over an Hour

- What are the limitations and disadvantages of autoclaves? Ensure Sterilization Success by Avoiding Common Pitfalls

- What are the risks of using an autoclave? Avoid Severe Burns and Sterilization Failures

- What are the maintenance requirements for an autoclave? Ensure Sterilization Safety and Longevity

- What is the function of a stainless steel high-pressure autoclave with a PTFE liner? Enhance CoO Synthesis Purity

- What is an autoclave laboratory equipment? The Ultimate Guide to Steam Sterilization

- What is the temperature of a low autoclave? The Critical Minimum for Sterilization

- What does an autoclave do in a microbiology laboratory? Ensuring Sterility and Safety for Your Research