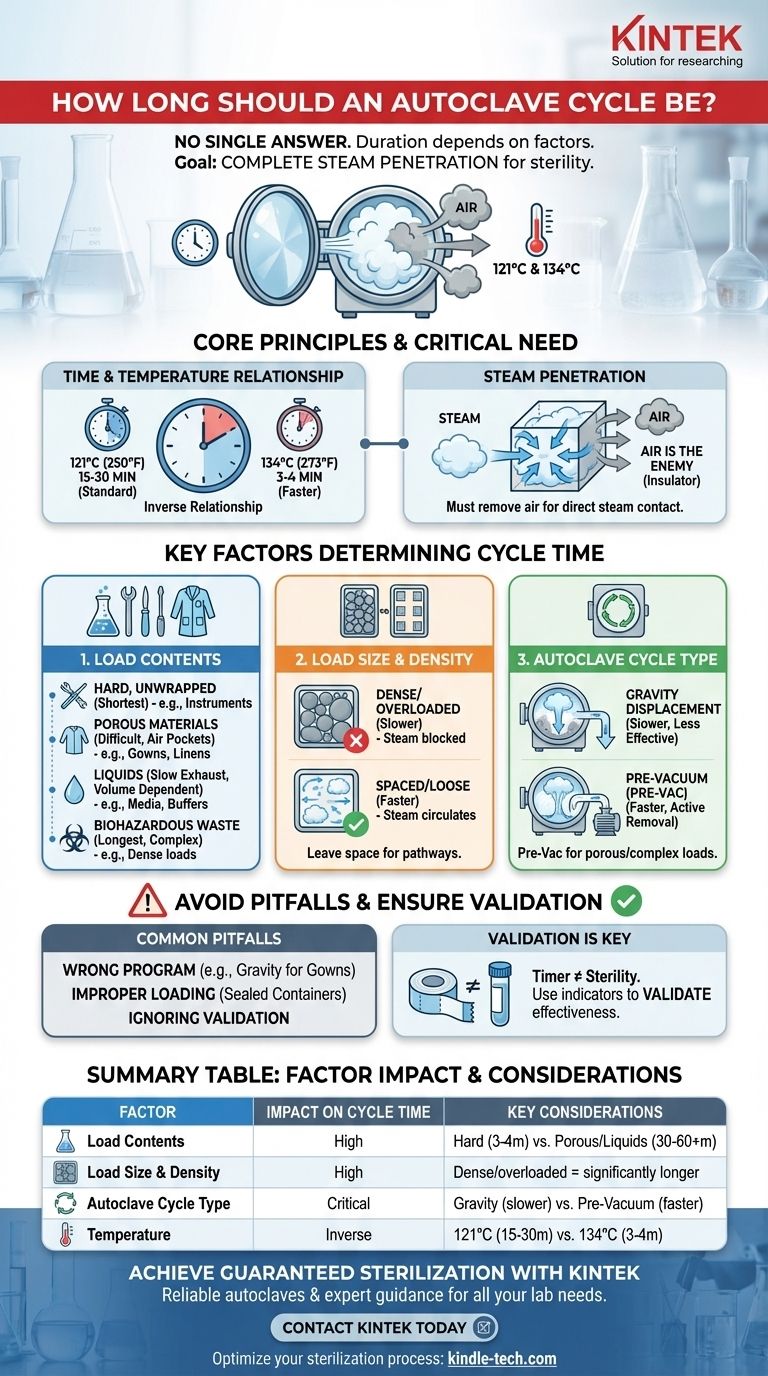

There is no single answer to how long an autoclave cycle should be. The correct duration is determined by a combination of factors, including what you are sterilizing, how it is packaged, and the type of autoclave you are using. A typical sterilization phase can range from as little as 3-4 minutes for simple instruments at high temperatures to over 60 minutes for complex or liquid loads.

The core principle is not about a specific duration, but about achieving complete steam penetration to all surfaces of the load for a sufficient amount of time at a specific temperature. Your goal is to ensure sterility, and the cycle time is merely the tool you adjust to achieve it.

The Core Principles of Sterilization

The entire purpose of an autoclave is to use high-pressure steam to kill all microorganisms, including resilient bacterial spores. This process depends on a precise relationship between time, temperature, and direct steam contact.

The Role of Time and Temperature

Sterilization is not instantaneous. Microorganisms are killed at a predictable rate at a given temperature.

A common industry standard is 121°C (250°F), which typically requires a sterilization exposure time of at least 15-30 minutes.

Alternatively, some cycles run at a higher temperature of 134°C (273°F), which can achieve sterility in as little as 3-4 minutes. This demonstrates the inverse relationship: higher temperatures require less time.

The Critical Need for Steam Penetration

Time and temperature are meaningless if steam cannot reach the item. Air is the enemy of sterilization because it acts as an insulator and prevents steam from making direct contact with surfaces.

The most significant factor influencing cycle time is the difficulty of removing air and allowing steam to penetrate the load.

Key Factors That Determine Cycle Time

To select the correct cycle, you must evaluate the nature of your load. Different materials require dramatically different approaches to ensure air is removed and steam makes contact.

Factor 1: The Contents of the Load

The physical properties of what you are sterilizing are the primary consideration.

- Hard, Unwrapped Goods: Simple glass or metal instruments have surfaces that are easy for steam to reach. These require the shortest cycles.

- Porous Materials: Items like surgical gowns, linens, or even multiple bags of pipette tips create many air pockets. These are very difficult to sterilize and require special cycles to actively remove air.

- Liquids: Media, buffers, or water require special "liquid cycles." These use a slower exhaust phase to prevent the liquid from boiling over violently as the chamber pressure drops. The volume of the liquid directly impacts time; a 2-liter flask takes much longer to heat than a 100 mL bottle.

- Biohazardous Waste: Waste loads are often complex and dense. They typically require longer cycle times (e.g., 45-60 minutes) to ensure complete heat penetration and sterilization, often dictated by institutional safety protocols.

Factor 2: Load Size and Density

How you load the autoclave is as important as what you load.

A large, densely packed load will take significantly longer for steam to penetrate than a small, loosely arranged one. Overloading an autoclave is a common cause of cycle failure.

Always leave space between items to create pathways for steam to circulate freely.

Factor 3: The Type of Autoclave Cycle

Autoclaves use different methods to remove air from the chamber, which directly impacts the total cycle time.

- Gravity Displacement Cycles: In this basic cycle, steam is introduced at the top of the chamber and, being less dense than air, "floats" on top, slowly displacing the air downwards and out through a drain. This process is slow and less effective for porous or complex loads.

- Pre-Vacuum (Pre-Vac) Cycles: These more advanced autoclaves use a vacuum pump to actively remove air from the chamber before introducing steam. This allows for near-instantaneous steam penetration, dramatically reducing cycle times and making it the required method for porous loads.

Understanding the Trade-offs and Common Pitfalls

Choosing the wrong cycle can lead to two outcomes: either the load is not sterile, or it is damaged. Understanding the risks is crucial for success.

Pitfall 1: Selecting the Wrong Program

The most common error is using a standard gravity cycle for porous items or a fast "hard goods" cycle for liquids.

Using a gravity cycle for gowns will likely leave air pockets, resulting in non-sterile items. Using a fast exhaust cycle for a bottle of media will cause it to boil over, creating a mess and resulting in a loss of volume.

Pitfall 2: Improper Loading

Overpacking the chamber or using sealed containers prevents steam from ever reaching the items. This is not a risk—it is a guarantee of sterilization failure.

Never place items in sealed containers unless they are specifically designed for steam sterilization and allow for venting.

Pitfall 3: Ignoring Cycle Validation

The timer on the autoclave only indicates that the machine has completed its programmed steps. It does not guarantee sterility.

Use chemical indicators (tape that changes color) in every load and biological indicators (vials of resistant spores) on a regular basis to validate that your chosen cycle settings are actually effective for your specific load.

Making the Right Choice for Your Goal

Always consult your institution's guidelines and the autoclave's manual. When in doubt, choose a more conservative (longer) cycle.

- If your primary focus is sterilizing unwrapped glassware or hard tools: You can likely use a standard gravity cycle of 15-30 minutes at 121°C.

- If your primary focus is sterilizing liquids like media or buffers: You must use a dedicated liquid cycle with slow exhaust, and the time will depend entirely on the volume of the largest container.

- If your primary focus is sterilizing wrapped instrument kits or porous loads like gowns: You must use a pre-vacuum cycle to ensure complete air removal and steam penetration.

- If your primary focus is decontaminating biohazardous waste: Default to a long gravity cycle (e.g., 60 minutes at 121°C) to ensure full penetration of dense, complex material.

Ultimately, the correct cycle time is the one you have proven to be effective for your specific application through careful validation.

Summary Table:

| Factor | Impact on Cycle Time | Key Considerations |

|---|---|---|

| Load Contents | High | Hard goods (3-4 min) vs. Porous/Liquids (30-60+ min) |

| Load Size & Density | High | Dense, overloaded chambers require significantly longer times |

| Autoclave Cycle Type | Critical | Gravity Displacement (slower) vs. Pre-Vacuum (faster) |

| Temperature | Inverse Relationship | 121°C (15-30 min) vs. 134°C (3-4 min) |

Achieve Guaranteed Sterilization with the Right Equipment

Selecting the correct autoclave cycle is critical for lab safety and efficiency. KINTEK specializes in providing reliable laboratory autoclaves and expert guidance to meet your specific sterilization needs, whether for hard goods, liquids, porous materials, or biohazardous waste.

Let our experts help you optimize your sterilization process. Contact KINTEK today to find the perfect autoclave solution for your lab.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- Do autoclaves use a lot of electricity? Managing Energy Costs in Your Sterilization Process

- What are the most important parameters for autoclave validation? Master Time, Temperature, and Pressure

- How does autoclave work step by step? A Guide to Reliable Sterilization

- What are examples of autoclave in microbiology? Essential Sterilization for Lab Safety & Accuracy

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the role of a high-pressure static autoclave in PWR coolant corrosion experiments? Essential Nuclear Testing

- What is the temperature effective for sterilization using autoclave? Achieve Sterile Conditions for Your Lab

- What instruments are used in autoclave sterilization? A Guide to Validating Sterility with Confidence