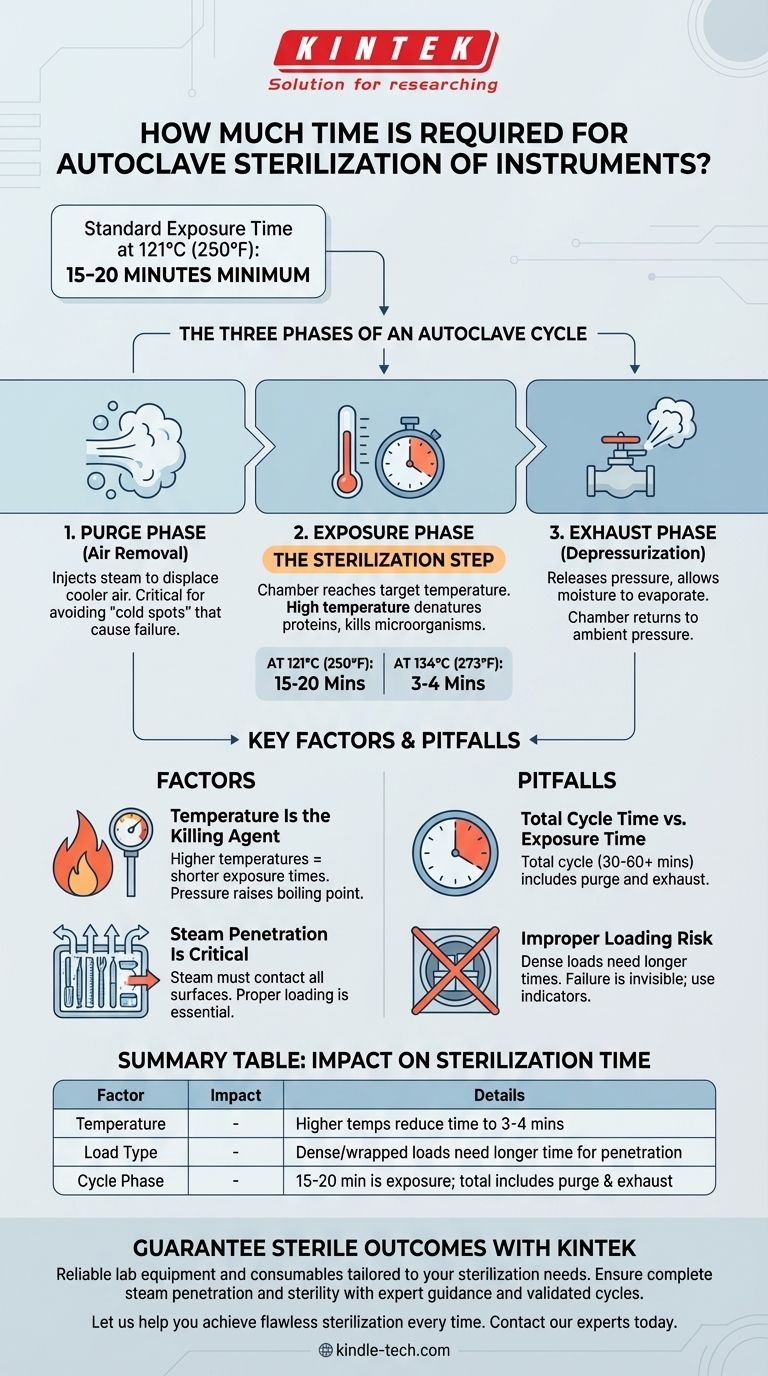

At a standard temperature of 121°C (250°F), the required exposure time for autoclave sterilization is a minimum of 15 to 20 minutes. However, this is only the sterilization phase itself. The total cycle time, from start to finish, is significantly longer because it must also include phases for purging air and exhausting steam.

The specific time required for sterilization is not a single number, but a variable that depends directly on temperature, steam penetration, and the type of load being processed. Understanding the entire autoclave cycle is more critical than memorizing one duration.

The Three Phases of an Autoclave Cycle

An autoclave does not simply "run" for a set time. The process is a structured sequence of three distinct phases, each with a critical purpose. The "sterilization time" refers to only one of these phases.

Phase 1: The Purge Phase (Air Removal)

Before sterilization can begin, all air must be removed from the chamber. If air pockets remain, they create "cold spots" that steam cannot reach, leading to sterilization failure.

This phase works by repeatedly injecting steam to displace the cooler, denser air, which is then vented out. The pressure and temperature in the chamber gradually increase as it fills with pure, saturated steam.

Phase 2: The Exposure Phase (Sterilization)

This is the actual sterilization step. Once all air is purged, the exhaust valve closes, allowing the chamber to reach the target temperature and pressure.

The load is then held at this setpoint for the prescribed duration. It is the high temperature of the steam, not the pressure itself, that denatures proteins and kills all microorganisms.

Phase 3: The Exhaust Phase (Depressurization)

After the exposure time is complete, an exhaust valve opens to slowly release pressure from the chamber. This returns the chamber to ambient pressure and allows any moisture on the sterilized items to evaporate into steam.

Key Factors That Determine Sterilization Time

Simply setting the timer is not enough to guarantee success. Sterilization efficacy depends on a relationship between time, temperature, and the nature of the items being sterilized.

Temperature Is the Killing Agent

Pressure is only the means to an end. An autoclave uses pressure to raise the boiling point of water, creating the high-temperature steam necessary for sterilization.

Higher temperatures can achieve sterilization in much less time. For example, a cycle at 134°C (273°F) may only require an exposure time of 3-4 minutes, compared to the 15-20 minutes needed at 121°C (250°F).

The Critical Role of Steam Penetration

For sterilization to occur, steam must make direct contact with every surface of every instrument. If steam cannot penetrate to the center of a pack or inside a container, that area will not be sterilized.

This is why proper loading is essential. Overloading the chamber or using improperly wrapped packs can block steam pathways and compromise the entire process. Densely packed or complex instruments require longer exposure times to ensure full penetration.

Understanding the Trade-offs and Pitfalls

Misunderstanding the autoclave process can lead to critical failures. The most common error is confusing the exposure time with the total cycle time.

Total Cycle Time vs. Exposure Time

The 15-20 minute recommendation refers only to the exposure phase. A complete autoclave cycle, including the purge and exhaust phases, typically takes from 30 to 60 minutes, or even longer depending on the load and the specific autoclave model.

The Risk of Improper Loading

A dense, tightly packed load requires a longer cycle. The heat and steam must penetrate to the very center of the load, which takes time. Assuming a short cycle will work for a large load is a dangerous mistake.

The Invisibility of Failure

A failed cycle looks no different from a successful one. If air was not fully purged, instruments may emerge from the autoclave appearing sterile but containing live microorganisms. This is why relying on validated cycles and process indicators is non-negotiable.

Making the Right Choice for Your Goal

To ensure effective sterilization, you must align the cycle parameters with the specific load you are processing. Always defer to the guidelines provided by the instrument and autoclave manufacturers.

- If your primary focus is sterilizing simple, unwrapped, non-porous instruments: A standard cycle of 15-20 minutes at 121°C is a reliable benchmark.

- If your primary focus is sterilizing wrapped kits, textiles, or dense loads: You must use a longer exposure time or a higher temperature cycle to ensure full steam penetration.

- If your primary focus is absolute safety and compliance: Rely on validated cycles confirmed with biological indicators, as these provide definitive proof that sterilization conditions were met throughout the load.

Mastering the principles of time, temperature, and steam penetration is the only way to guarantee a truly sterile outcome.

Summary Table:

| Factor | Impact on Sterilization Time |

|---|---|

| Temperature | Higher temperatures (e.g., 134°C) reduce exposure time to 3-4 minutes. |

| Load Type | Dense, wrapped, or complex loads require longer times for full steam penetration. |

| Cycle Phase | The 15-20 min is only the exposure phase; total cycle includes purge and exhaust phases. |

Guarantee Sterile Outcomes with the Right Equipment from KINTEK

Ensuring your autoclave cycles are effective is critical for laboratory safety and compliance. KINTEK specializes in providing reliable lab equipment and consumables tailored to your sterilization needs. Our expertise helps you select the right autoclave and validate cycles for your specific instruments and loads, ensuring complete steam penetration and sterility.

Let us help you achieve flawless sterilization every time. Contact our experts today to discuss your laboratory's requirements and enhance your safety protocols.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What are the settings for autoclaving glassware? A Guide to Effective Sterilization

- What precautions should be taken during autoclave in laboratory? A Complete Safety Guide to Prevent Burns and Explosions

- What is the size of the autoclave? Choose the Right Capacity for Your Lab

- What instruments are used in autoclave sterilization? A Guide to Validating Sterility with Confidence

- What are the settings for autoclave sterilization? Ensure Reliable Sterility with Proper Parameters