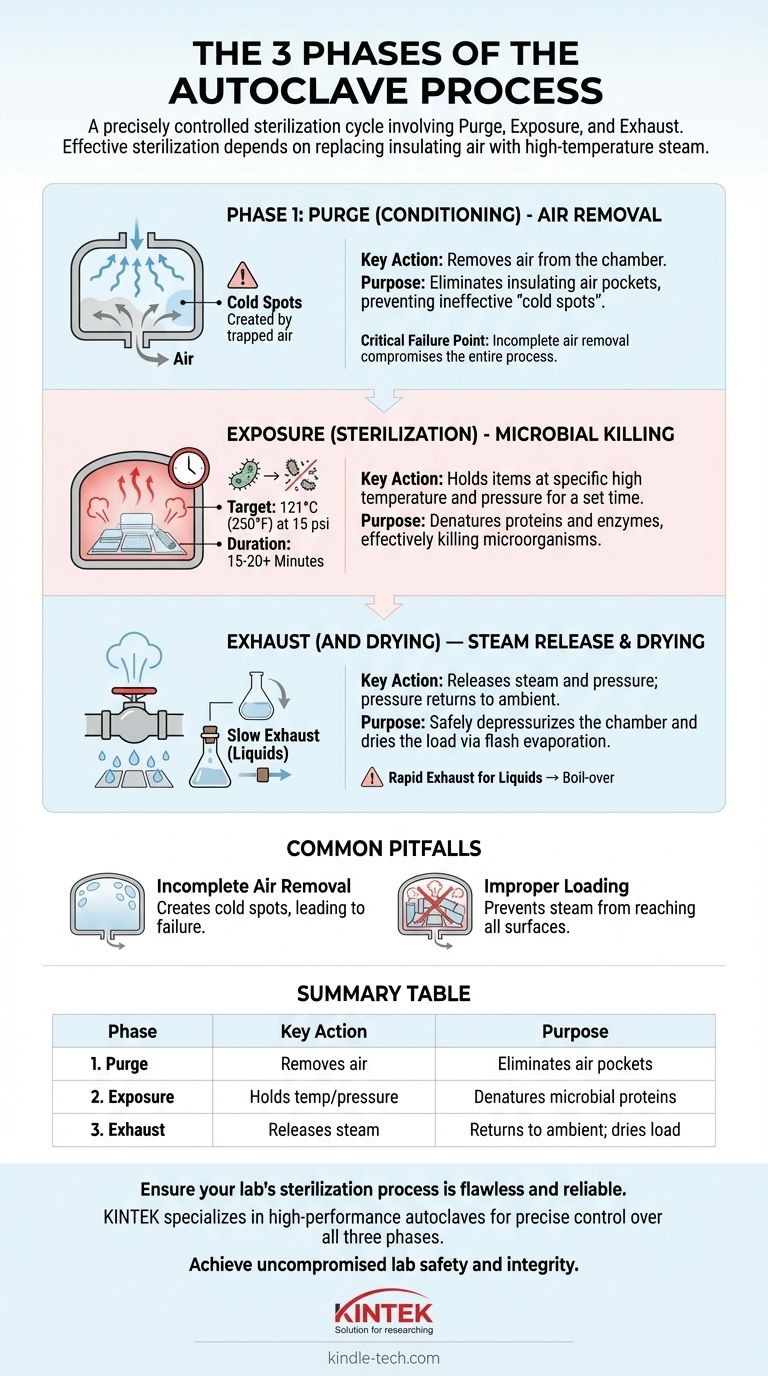

At its core, the autoclave process is a precisely controlled sterilization cycle that unfolds in three distinct phases. These phases are the Purge/Conditioning phase, where air is removed; the Exposure/Sterilization phase, where the items are held at a specific temperature and pressure for a set time; and the Exhaust phase, where steam is released and the items are dried.

Understanding these three phases is not just about memorizing steps. It's about recognizing that effective sterilization depends entirely on replacing all insulating air with penetrating, high-temperature steam. Any failure in the first phase will compromise the entire process.

The Core Principle: Why Steam is More Than Just Heat

Before examining the phases, it's critical to understand why autoclaves use pressurized steam. It's not just about getting things hot; it's about how that heat is delivered.

The Role of Pressure and Temperature

Under normal atmospheric pressure, water boils at 100°C (212°F). By increasing the pressure inside a sealed vessel, an autoclave allows water to exist as saturated steam at much higher temperatures, typically 121°C (250°F) at 15 psi. This superheated steam is what kills microorganisms.

Saturated Steam vs. Trapped Air

The true enemy of sterilization is trapped air. Air is a very poor conductor of heat. If pockets of air remain inside the chamber or within the items being sterilized, they create "cold spots". These spots will not reach the required sterilization temperature, allowing microbes to survive even if the autoclave's sensors report a successful cycle.

A Phase-by-Phase Breakdown of the Sterilization Cycle

The entire three-phase cycle is designed to solve the problem of trapped air and ensure every surface reaches the target temperature for the required duration.

Phase 1: Purge (or Conditioning)

The first and most critical phase is dedicated to removing all air from the chamber. In a common "gravity displacement" autoclave, steam is pumped into the chamber. Because steam is less dense than cool air, it fills the chamber from the top down, forcing the heavier air out through a drain at the bottom.

This phase continues until the chamber is filled only with saturated steam, ensuring there are no insulating air pockets left.

Phase 2: Exposure (or Sterilization)

Once the air is purged, the exhaust valve closes, sealing the chamber. Steam continues to be admitted until the interior reaches the target temperature and pressure (e.g., 121°C and 15 psi).

The clock for the sterilization "time" starts now. The load is held at this setpoint for a specified duration—often 15-20 minutes or longer—which is sufficient time for the penetrating heat to denature the proteins and enzymes within any microorganisms, effectively killing them.

Phase 3: Exhaust (and Drying)

After the exposure time is complete, the exhaust valve opens and the steam is slowly released from the chamber. The pressure gradually returns to ambient levels.

As the pressure drops, the superheated water remaining on the surfaces of the items will flash-evaporate, which helps to dry the load. This phase must be performed slowly, especially for liquids, to prevent violent boiling and "boil-over".

Understanding Common Pitfalls

A failure in any phase can lead to an incomplete sterilization cycle. Understanding these failure points is key to proper use.

Incomplete Air Removal

This is the single most common cause of sterilization failure. If the purge cycle is too short or the autoclave is improperly loaded, air pockets will remain and create cold spots, rendering the process ineffective.

Improper Loading

Over-packing the chamber or wrapping items in materials that are not permeable to steam (like aluminum foil) prevents steam from reaching all surfaces. There must be adequate space for steam to circulate freely.

Rapid Exhaust for Liquids

When sterilizing liquids like laboratory media, a fast exhaust cycle will cause a sudden pressure drop, making the superheated liquid boil violently. This can cause stoppers to pop, media to boil out of the containers, and potential loss of the sample.

Applying This Knowledge to Your Process

Your specific use case determines which phase and precautions are most critical.

- If your primary focus is sterilizing solid instruments: Ensure items are wrapped and loaded in a way that allows for complete air removal and steam penetration during the Purge phase.

- If your primary focus is sterilizing liquids or media: Pay close attention to using a slow, controlled Exhaust phase to prevent boil-over and sample loss.

- If your primary focus is ensuring process integrity: Use chemical and biological indicators placed in the most challenging parts of your load to verify that the Exposure phase achieved its killing temperature everywhere.

By understanding the purpose behind each phase, you move from simply operating a machine to guaranteeing a reliable and safe sterilization outcome.

Summary Table:

| Phase | Key Action | Purpose |

|---|---|---|

| 1. Purge (Conditioning) | Removes air from the chamber | Eliminates insulating air pockets to prevent 'cold spots' |

| 2. Exposure (Sterilization) | Holds items at high temperature/pressure | Denatures microbial proteins for a set time (e.g., 121°C for 15-20 mins) |

| 3. Exhaust (and Drying) | Releases steam and pressure | Safely returns chamber to ambient pressure and dries the load |

Ensure your lab's sterilization process is flawless and reliable.

Understanding the autoclave cycle is the first step; having the right equipment is what guarantees success. KINTEK specializes in high-performance autoclaves and lab equipment designed for precise control over all three phases—Purge, Exposure, and Exhaust—ensuring complete sterilization for your instruments, media, and samples.

Let us help you achieve uncompromised lab safety and integrity. Contact our experts today to find the perfect autoclave solution for your specific laboratory needs.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment