At its core, the autoclave is an exceptionally effective sterilization device, prized for its ability to kill all forms of microbial life, including resilient bacterial spores. It achieves this using high-pressure saturated steam, making it a fast, economical, and reliable method for a wide range of applications. However, its very mechanism—intense heat and moisture—is also its primary limitation.

While the autoclave offers an unparalleled combination of speed, cost-effectiveness, and microbial lethality, its reliance on high-temperature steam makes it fundamentally unsuitable for any material that can be damaged by heat or is impenetrable by moisture.

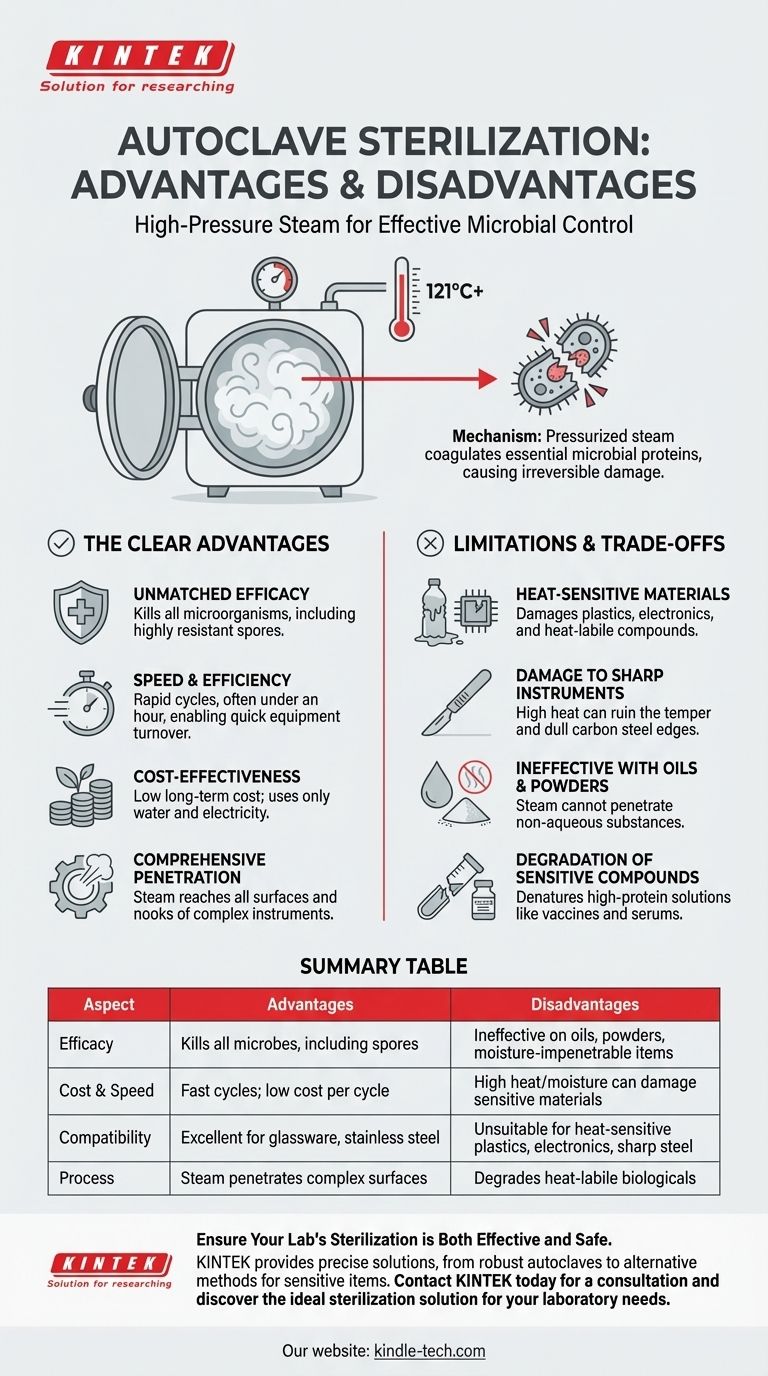

How an Autoclave Achieves Sterilization

To understand its advantages and disadvantages, you must first understand its mechanism. The autoclave does not sterilize with pressure alone; it uses pressure to manipulate the properties of water.

The Role of Pressurized Steam

Under normal atmospheric pressure, water boils at 100°C (212°F). By increasing the pressure inside its sealed chamber, an autoclave raises the boiling point of water. This allows it to create steam at temperatures of 121°C or higher.

It is this high-temperature steam, not the pressure itself, that serves as the sterilizing agent.

The Mechanism of Microbial Destruction

Moist heat is far more effective at transferring thermal energy than dry heat. When this high-temperature steam condenses on the surfaces of the items inside, it rapidly transfers heat.

This intense heat causes the coagulation of essential microbial proteins, a process similar to cooking an egg. This damage is irreversible, destroying the microbe's cellular functions and leading to its death.

The Clear Advantages of Autoclave Sterilization

For compatible materials, the autoclave is often the preferred method due to several key benefits.

Unmatched Efficacy

The use of moist heat under pressure is one of the most dependable methods for destroying all microorganisms, including the highly resistant endospores produced by certain bacteria.

Speed and Efficiency

Compared to other methods like dry heat or chemical sterilization, autoclave cycles are remarkably short, often completing in under an hour depending on the load. This allows for rapid turnover of equipment.

Cost-Effectiveness

Autoclaves operate using only water and electricity. They do not require expensive chemical agents or disposables, making the cost per cycle very low over the long term.

Comprehensive Penetration

When items are loaded correctly, steam can penetrate all surfaces, nooks, and crannies of complex instruments, ensuring a thorough sterilization that chemical wipes might miss.

Understanding the Limitations and Trade-offs

The autoclave's power is also its biggest constraint. Its effectiveness is entirely dependent on heat and moisture, which makes it damaging or useless for certain categories of materials.

Incompatibility with Heat-Sensitive Materials

Many common materials cannot withstand the high temperatures of an autoclave. Plastics may melt or warp, and sensitive electronic components will be destroyed.

Damage to Sharp Instruments

While stainless steel surgical tools handle autoclaving well, high-grade carbon steel instruments, such as certain scalpels and scissors, can be affected. The high heat can ruin the temper of the metal, causing the sharp edges to become dull.

Ineffectiveness with Oils and Powders

Autoclaving is a water-based process. It cannot be used to sterilize oily substances, waxes, or dry powders, as the steam cannot penetrate these materials to deliver lethal heat.

Degradation of Sensitive Compounds

Many biological and chemical compounds are degraded by heat. High-protein solutions like vaccines, serums, and some microbial growth factors will be denatured and rendered useless by the autoclave's heat. These require non-thermal methods like sterile filtration.

Making the Right Choice for Your Application

Selecting a sterilization method is a critical decision based on material compatibility. Using an autoclave incorrectly can either destroy valuable equipment or, more dangerously, fail to sterilize it.

- If your primary focus is sterilizing reusable glassware, stainless steel instruments, or standard microbial media: The autoclave is your most efficient, reliable, and cost-effective method.

- If you are working with heat-sensitive polymers, delicate electronics, or sharp carbon-steel blades: You must use an alternative low-temperature method like Ethylene Oxide (EtO) gas or vaporized hydrogen peroxide.

- If you need to sterilize non-aqueous materials like oils, powders, or heat-labile solutions: Heat-free sterile filtration is the appropriate and necessary choice.

Understanding these fundamental principles allows you to select the correct sterilization method with confidence, ensuring both safety and material integrity.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Efficacy | Kills all microorganisms, including spores | Ineffective on oils, powders, and moisture-impenetrable items |

| Cost & Speed | Fast cycles; low cost per cycle (uses only water & electricity) | High heat and moisture can damage sensitive materials |

| Material Compatibility | Excellent for glassware, stainless steel, and surgical tools | Unsuitable for heat-sensitive plastics, electronics, and sharp carbon steel |

| Process | Steam penetrates complex instrument surfaces thoroughly | Degrades heat-labile biologicals (e.g., vaccines, serums) |

Ensure Your Lab's Sterilization is Both Effective and Safe

Choosing the right sterilization method is critical for protecting your equipment and ensuring safety. KINTEK specializes in providing the precise lab equipment you need, from robust autoclaves for heat-tolerant materials to alternative solutions for sensitive items.

Let us help you select the perfect equipment for your specific application. Our experts are ready to provide personalized advice to enhance your lab's efficiency and integrity.

Contact KINTEK today for a consultation and discover the ideal sterilization solution for your laboratory needs.

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What role does a laboratory autoclave play in the separation of lignin? High-Purity Extraction for Biomass Research

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy