When it comes to terminal sterilization, the autoclave is the established gold standard across medical and research fields. Its primary advantages are its unmatched ability to kill even the most resistant microorganisms, its operational efficiency, and its cost-effectiveness, achieving sterilization using only high-pressure steam without the need for chemical agents.

The autoclave's core advantage is not just that it gets things hot, but that it uses moist heat under pressure. This combination allows it to rapidly penetrate materials and destroy all forms of microbial life, including resilient bacterial spores, making it the most reliable method for heat- and moisture-tolerant items.

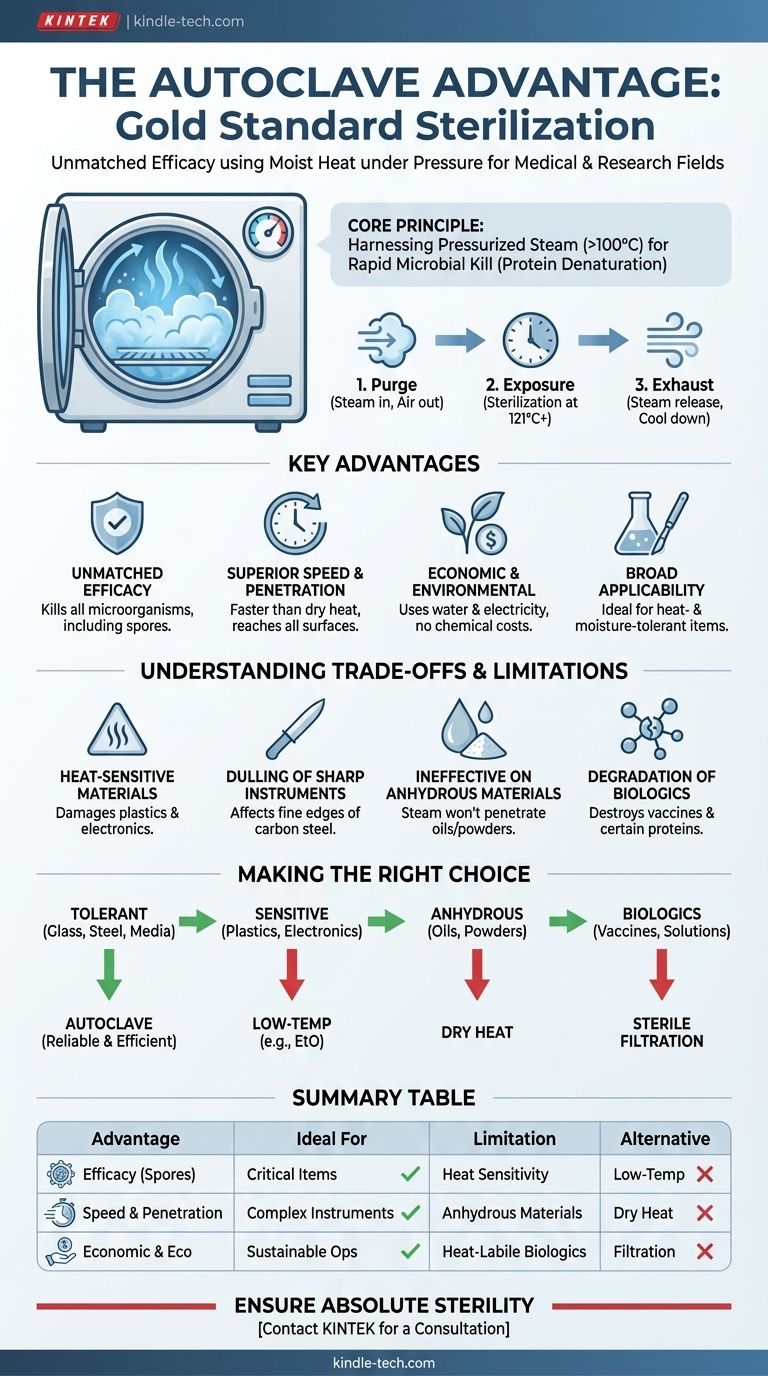

The Core Principle: How Autoclaves Achieve Sterility

To appreciate its advantages, you must first understand how an autoclave works. It isn't simply a hot oven; it's a precisely engineered system that manipulates physical principles to ensure total microbial destruction.

Harnessing Pressurized Steam

An autoclave works by increasing the pressure within its chamber. This increased pressure raises the boiling point of water far above 100°C (212°F).

This superheated, saturated steam is the active sterilizing agent. It carries significantly more thermal energy than dry air at the same temperature.

The Mechanism of Microbial Kill

The moisture in the steam is the critical component. It rapidly transfers heat to microorganisms, causing an irreversible coagulation and denaturation of essential proteins and enzymes.

This process is far more efficient than the slow oxidation that occurs during dry heat sterilization, leading to a much faster and more reliable kill. Even highly resistant bacterial endospores cannot survive these conditions.

The Three-Phase Sterilization Cycle

A typical autoclave cycle ensures that this process is executed correctly:

- Purge Phase: Steam is injected to displace the cooler, less effective air from the chamber.

- Exposure (Sterilization) Phase: The chamber is sealed, and pressure and temperature are maintained at the sterilization setpoint (e.g., 121°C for at least 15 minutes) for the prescribed time.

- Exhaust Phase: The steam is released, and the chamber pressure returns to ambient, allowing for the safe removal of sterilized items.

Key Advantages of Autoclave Sterilization

The operational benefits of the autoclave stem directly from its use of moist heat under pressure. These advantages make it the preferred choice for a vast range of applications.

Unmatched Efficacy

The autoclave provides a high level of sterility assurance. Its ability to kill the full spectrum of microorganisms, from common bacteria to tough spores, makes it exceptionally reliable.

Superior Speed and Penetration

Moist heat sterilization is significantly faster than dry heat. The steam effectively penetrates porous materials and reaches all surfaces of complex instruments, ensuring no part is left unsterilized.

Economic and Environmental Benefits

Autoclaves are highly economical to operate. Their primary consumables are water and electricity, eliminating the ongoing cost and disposal concerns of chemical sterilants.

Broad Applicability for Tolerant Materials

This method is ideal for a wide variety of common laboratory and medical items. This includes surgical and dental instruments, glassware, microbial growth media, and other aqueous solutions.

Understanding the Trade-offs: When Not to Use an Autoclave

Being a trusted expert means knowing a tool's limitations. An autoclave is powerful, but it is not a universal solution. Using it on the wrong materials can cause irreparable damage.

Damage to Heat-Sensitive Materials

Many plastics will melt or warp at the high temperatures inside an autoclave. Sensitive electronic equipment would be immediately destroyed.

Dulling of Sharp Instruments

While an autoclave is perfect for stainless steel instruments, the high heat can dull the fine edges of high-grade carbon steel scalpels and scissors.

Ineffectiveness with Oils and Powders

An autoclave relies on steam. Anhydrous materials like oils, greases, and powders cannot be sterilized this way because the steam cannot penetrate them effectively.

Degradation of Certain Biologics

Many complex biological compounds are destroyed by heat. Items like vaccines, serums, and certain proteins (such as urea) will degrade and must be sterilized by other methods, such as filtration.

Making the Right Choice for Your Goal

Selecting the correct sterilization method is critical for ensuring both safety and the integrity of your materials. Use the autoclave's strengths where they apply and choose an alternative when they do not.

- If your primary focus is sterilizing glassware, surgical steel, or microbial media: The autoclave is your most reliable, efficient, and cost-effective choice.

- If your primary focus is sterilizing heat-sensitive plastics or delicate electronics: You must explore low-temperature alternatives like ethylene oxide (EtO) or vaporized hydrogen peroxide.

- If your primary focus is sterilizing anhydrous materials like oils or powders: Dry heat sterilization is the appropriate method, as an autoclave will be completely ineffective.

- If your primary focus is sterilizing heat-labile solutions or biologics: Sterile filtration is the necessary method to remove microbes without damaging the product.

Understanding these principles allows you to use the autoclave not just as a tool, but as a precise instrument for ensuring absolute sterility.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Unmatched Efficacy | Kills all microorganisms, including bacterial spores. | High sterility assurance for critical items. |

| Superior Speed & Penetration | Moist heat penetrates materials faster than dry heat. | Complex instruments, porous loads, glassware. |

| Economic & Environmental | Uses only steam and electricity; no chemical costs. | Cost-effective, sustainable operations. |

| Broad Applicability | Reliable for heat- and moisture-tolerant materials. | Surgical instruments, media, aqueous solutions. |

| Limitation | Not Suitable For | Alternative Method |

| Heat Sensitivity | Melts plastics, damages electronics. | Low-temperature sterilization (e.g., EtO). |

| Anhydrous Materials | Ineffective on oils, greases, powders. | Dry heat sterilization. |

| Heat-Labile Biologics | Degrades vaccines, sensitive proteins. | Sterile filtration. |

Ensure Absolute Sterility in Your Laboratory

Ready to leverage the gold standard in sterilization for your lab's critical instruments and media? KINTEK specializes in providing reliable autoclaves and expert support to meet your laboratory's exact needs.

We understand that your work demands precision and reliability. By choosing KINTEK, you gain a partner dedicated to ensuring your sterilization processes are efficient, cost-effective, and compliant.

Contact us today to find the perfect autoclave solution for your laboratory. Let's discuss how we can enhance your lab's safety and efficiency together.

Contact KINTEK for a Consultation

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- Why is the prevention of air entrapment critical for the autoclave sterilization process? Ensure 100% Sterility Today

- What are the different types of autoclaves in hospitals? Choose the Right Sterilization for Your Needs

- What is the most common hazard of using an autoclave? Prevent Severe Thermal Burns and Accidents

- In what industries and applications are steam sterilizers or autoclaves used? Discover Key Uses Across 4 Major Sectors

- How does a high-pressure hydrothermal autoclave facilitate the synthesis of BiVO4@PANI nanocomposites? Unlock Precision.

- What is a rotary retort? Achieve Faster, Superior Sterilization for Viscous Foods

- Why do we do 121 degree sterilization? The Science Behind Guaranteed Sterility

- What are the considerations for autoclave? Ensure Sterilization Success and Safety