In essence, stainless steel reactors are the industry standard for their unmatched combination of chemical resistance, mechanical durability, and hygienic properties. This makes them a highly reliable and versatile choice for a vast range of chemical, pharmaceutical, and manufacturing processes, particularly those involving demanding physical conditions or stringent purity requirements.

The primary advantage of a stainless steel reactor is not a single feature, but its balanced profile. It provides excellent durability and chemical resistance for most applications, is easy to clean and maintain, and can be customized, making it a robust and dependable default choice for process engineering.

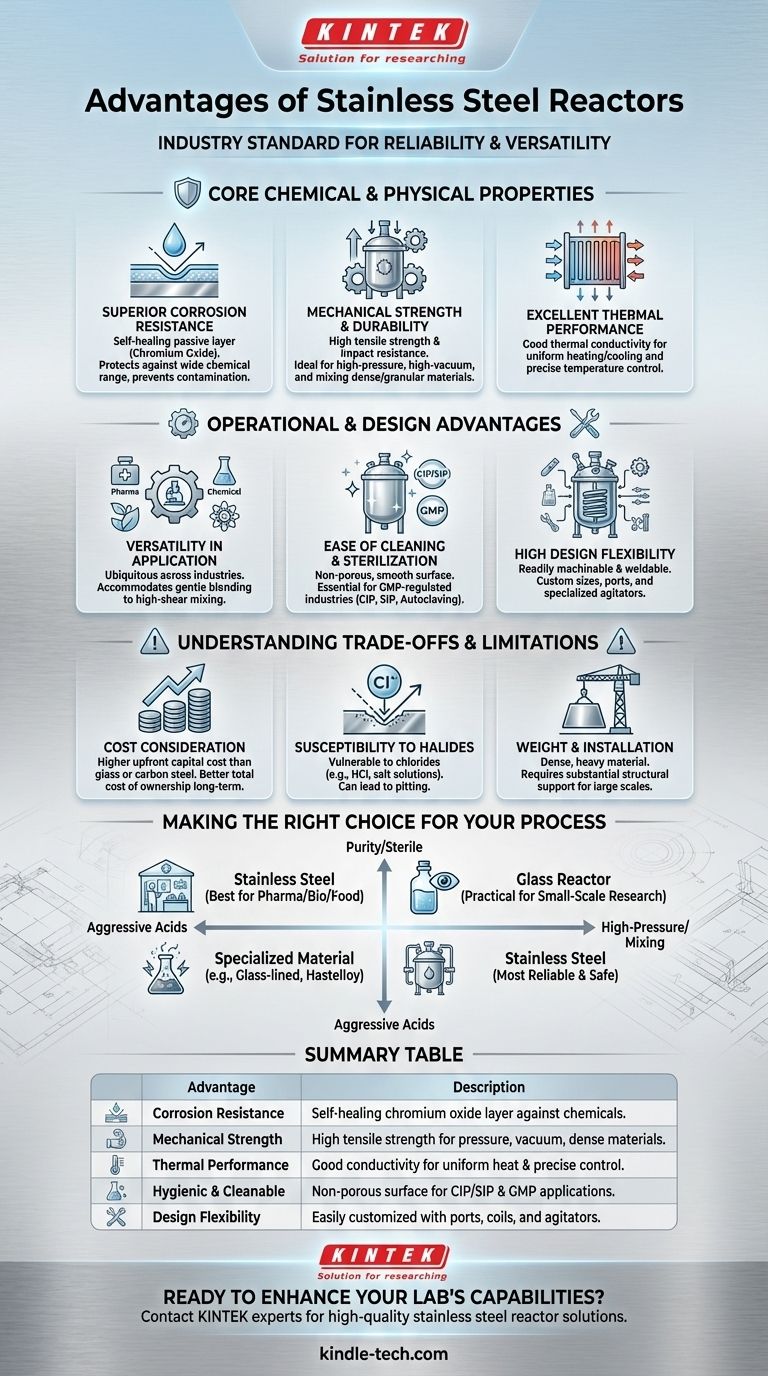

Core Chemical and Physical Properties

The advantages of stainless steel stem from the fundamental properties of the material itself. It is an iron-based alloy containing a minimum of 10.5% chromium, which is the key to its performance.

Superior Corrosion Resistance

The chromium in stainless steel reacts with oxygen in the air to form a thin, stable, and non-reactive layer of chromium oxide on the surface. This passive layer is self-healing; if scratched or damaged, it instantly reforms, providing continuous protection against a wide range of chemicals and preventing product contamination.

Mechanical Strength and Durability

Stainless steel exhibits high tensile strength and impact resistance. This makes it ideal for high-pressure or high-vacuum operations and for mixing dense or granular materials, which can exert significant physical stress on the reactor vessel and agitator. It withstands mechanical shock far better than alternatives like glass.

Excellent Thermal Performance

The material possesses good thermal conductivity, allowing for efficient and uniform heat transfer. This is critical for controlling reaction temperatures, whether you are using a jacket for heating with steam or cooling with a chilled fluid. This ensures precise process control and consistent product quality.

Operational and Design Advantages

Beyond its core properties, stainless steel provides significant benefits in the design, operation, and maintenance of a reactor system.

Versatility in Application

From pharmaceuticals and food processing to fine chemicals and polymers, stainless steel reactors are ubiquitous. Their inert nature and durability allow them to be used for countless processes, accommodating everything from gentle blending to high-shear mixing with various stirring methods.

Ease of Cleaning and Sterilization

The surface of stainless steel is non-porous, smooth, and crevice-free when properly fabricated. This makes it exceptionally easy to clean, sanitize, and sterilize using methods like clean-in-place (CIP), sterilize-in-place (SIP), or autoclaving, which is a non-negotiable requirement in GMP-regulated industries.

High Design Flexibility

Stainless steel is readily machinable and weldable. This allows for the fabrication of reactors in almost any size and configuration, with customized ports for instrumentation, complex internal coils, or specialized agitator systems designed for unique process demands.

Understanding the Trade-offs and Limitations

While highly advantageous, stainless steel is not the optimal choice for every scenario. Understanding its limitations is key to making an informed decision.

The Consideration of Cost

The upfront capital cost of a stainless steel reactor is significantly higher than that of a glass or carbon steel reactor. While its longevity and low maintenance often provide a better total cost of ownership, the initial investment can be a barrier.

Susceptibility to Certain Chemicals

Stainless steel is not completely immune to all forms of corrosion. It is particularly vulnerable to attack by halide ions, especially chlorides (found in hydrochloric acid and salt solutions). Prolonged exposure can lead to localized pitting and crevice corrosion, compromising the vessel's integrity.

Weight and Installation Demands

Stainless steel is a dense, heavy material. Large-scale reactors require substantial structural support and specialized equipment for installation. For small, lab-scale setups, a heavier steel reactor may be less practical than a lighter glass alternative.

Making the Right Choice for Your Process

Selecting the right reactor material requires aligning its properties with the specific demands of your chemical process, budget, and operational scale.

- If your primary focus is product purity and sterile operation: Stainless steel is the superior choice for pharmaceutical, biotech, or food-grade applications due to its cleanability and inertness.

- If your primary focus is cost-sensitive, small-scale research with visual monitoring: A glass reactor is often more practical, allowing you to observe the reaction directly at a lower upfront cost.

- If your primary focus is handling highly aggressive acids (like concentrated HCl): You must consider a more specialized and expensive material, such as a glass-lined steel reactor or a high-nickel alloy like Hastelloy.

- If your primary focus is high-pressure synthesis or robust mechanical mixing: The strength and durability of stainless steel make it the most reliable and safest option.

Ultimately, choosing a reactor is an engineering decision that balances performance, safety, and cost to achieve your specific process goal.

Summary Table:

| Advantage | Description |

|---|---|

| Corrosion Resistance | Self-healing chromium oxide layer protects against a wide range of chemicals. |

| Mechanical Strength | High tensile strength for high-pressure, high-vacuum, and dense material mixing. |

| Thermal Performance | Good thermal conductivity for uniform heating and precise temperature control. |

| Hygienic & Cleanable | Non-porous, smooth surface ideal for CIP/SIP and sterile GMP applications. |

| Design Flexibility | Easily customized with ports, coils, and agitators for unique process needs. |

Ready to enhance your lab's capabilities with a reliable stainless steel reactor?

At KINTEK, we specialize in high-quality lab equipment, including robust stainless steel reactors designed for the demanding needs of pharmaceutical, chemical, and manufacturing processes. Our reactors deliver the durability, purity, and performance your work requires.

Contact our experts today to discuss your specific application and find the perfect reactor solution for your laboratory.

Visual Guide

Related Products

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis

- What is the function of high-pressure reactors and autoclaves in HTL? Unlocking Efficient Bio-Fuel from Wet Microalgae

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data