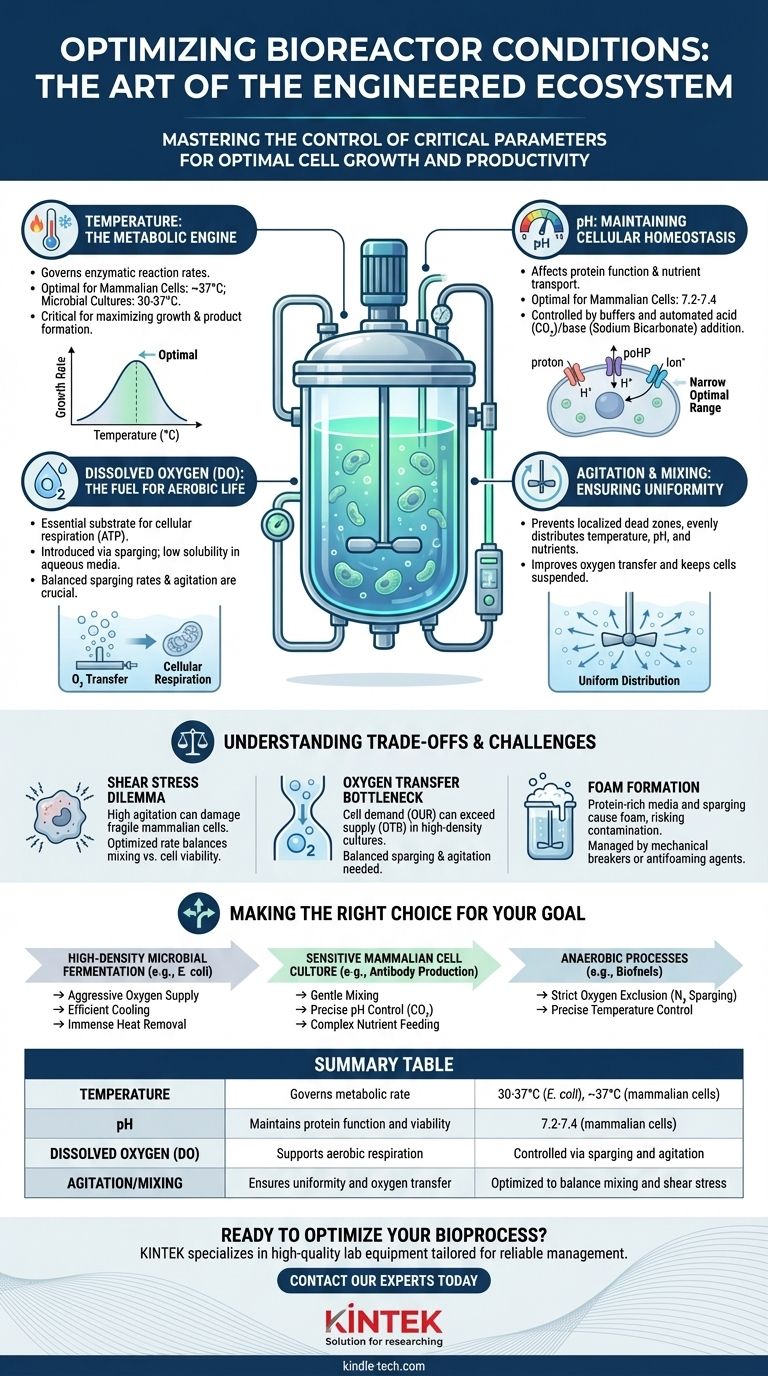

In short, a bioreactor meticulously controls a set of critical environmental conditions to ensure optimal cell growth and productivity. The most fundamental parameters maintained are temperature, pH, dissolved oxygen (DO), and agitation for mixing. These are supported by a controlled supply of nutrients and the removal of metabolic waste products.

A bioreactor is not just a container; it is an engineered ecosystem designed to replicate and optimize the ideal physiological environment for a specific population of cells or microorganisms. Mastering the control of these conditions is the difference between a failed batch and a high-yield bioprocess.

The Core Pillars of Bioreactor Control

To achieve a successful culture, a bioreactor must precisely manage several interconnected variables. Each one serves a distinct biological purpose, and a failure in one can cascade through the entire system.

Temperature: The Engine of Metabolism

Temperature directly governs the rate of all enzymatic reactions within the cells, making it one of the most critical parameters.

An optimal temperature maximizes the metabolic rate for growth and product formation. Even a slight deviation can slow down processes or, in extreme cases, cause irreversible damage and cell death. For example, mammalian cells (like CHO cells) thrive around 37°C, while many microbial cultures (like E. coli) prefer temperatures between 30-37°C.

pH: Maintaining Cellular Homeostasis

The pH of the culture medium affects the function of proteins, nutrient transport across the cell membrane, and overall cell viability.

Cells have a very narrow optimal pH range. For mammalian cells, this is typically between 7.2 and 7.4. Bioreactors maintain this by using a buffer system in the media and by automatically adding acid (often gaseous CO₂) or a base (like sodium bicarbonate) to correct any deviations caused by cellular metabolism.

Dissolved Oxygen (DO): The Fuel for Aerobic Life

For aerobic organisms, oxygen is a critical substrate for cellular respiration, the primary process for generating energy (ATP).

The concentration of dissolved oxygen (DO) is a key limiting factor because oxygen has low solubility in aqueous media. Bioreactors introduce oxygen through a process called sparging, where filtered air or pure oxygen is bubbled through the culture. The level of DO must be high enough to support metabolism but not so high that it becomes toxic through the creation of reactive oxygen species.

Agitation and Mixing: Ensuring Uniformity

A bioreactor is not a static environment. Constant mixing, driven by an impeller, is essential for several reasons.

Agitation ensures that temperature, pH, and nutrients are evenly distributed throughout the vessel, preventing localized dead zones. It also helps break up sparged gas bubbles to improve oxygen transfer into the liquid and keeps the cells suspended uniformly rather than settling at the bottom.

Understanding the Trade-offs and Challenges

Maintaining these ideal conditions is a constant balancing act, with several inherent engineering challenges.

The Shear Stress Dilemma

While agitation is necessary for mixing, high impeller speeds can create powerful hydrodynamic forces known as shear stress.

Microbial cells are generally robust, but fragile mammalian cells can be easily damaged or killed by excessive shear. Therefore, the agitation rate must be carefully optimized to provide adequate mixing without compromising cell viability.

The Oxygen Transfer Bottleneck

As cell density increases, the culture's demand for oxygen (the Oxygen Uptake Rate, or OUR) can exceed the bioreactor's ability to supply it (the Oxygen Transfer Rate, or OTR).

This is a common bottleneck in high-density cultures. Engineers must balance sparging rates and agitation to maximize oxygen transfer without creating excessive foam or shear stress.

Foam Formation

Sparging gas into a protein-rich culture medium is a perfect recipe for foam.

Excessive foam can block exhaust filters, leading to pressure buildup and potential contamination. Bioreactors manage this through mechanical foam breakers or the automated addition of chemical antifoaming agents.

Making the Right Choice for Your Goal

The specific setpoints and control strategies for a bioreactor depend entirely on the cells being cultured and the desired outcome.

- If your primary focus is high-density microbial fermentation (e.g., E. coli): Your priority will be aggressive oxygen supply and an efficient cooling system to remove the immense heat generated by rapid metabolism.

- If your primary focus is sensitive mammalian cell culture (e.g., for antibody production): You will prioritize gentle mixing to minimize shear stress, precise pH control using CO₂, and potentially complex nutrient feeding strategies.

- If your primary focus is an anaerobic process (e.g., certain biofuel productions): The key is the strict exclusion of oxygen by sparging with an inert gas like nitrogen, alongside precise temperature control.

Ultimately, mastering the interplay of these conditions is the foundational skill for successfully translating a biological process from the lab bench to industrial-scale production.

Summary Table:

| Condition | Purpose | Typical Range/Example |

|---|---|---|

| Temperature | Governs metabolic rate | 30-37°C (E. coli), ~37°C (mammalian cells) |

| pH | Maintains protein function and viability | 7.2-7.4 (mammalian cells) |

| Dissolved Oxygen (DO) | Supports aerobic respiration | Controlled via sparging and agitation |

| Agitation/Mixing | Ensures uniformity and oxygen transfer | Optimized to balance mixing and shear stress |

Ready to optimize your bioprocess with precision-controlled bioreactor conditions? KINTEK specializes in high-quality lab equipment and consumables tailored for reliable temperature, pH, and dissolved oxygen management—whether you're scaling microbial fermentation or cultivating sensitive mammalian cells. Contact our experts today to discuss how our solutions can enhance your lab's productivity and yield.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What functions do electrolytic cells perform in PEC water splitting? Optimize Your Photoelectrochemical Research

- What are the advantages of using a PTFE deposition tank for EPD? Achieve Unmatched Coating Precision on Stainless Steel

- What precautions should be taken regarding temperature when using an all-PTFE electrolytic cell? Ensure Safe & Accurate Experiments

- What is the precaution regarding temperature when using an all-PTFE electrolytic cell? Essential Thermal Safety Tips

- What are the primary functions of a high-performance electrolytic cell in the eCO2R process? Optimize Your Lab Results