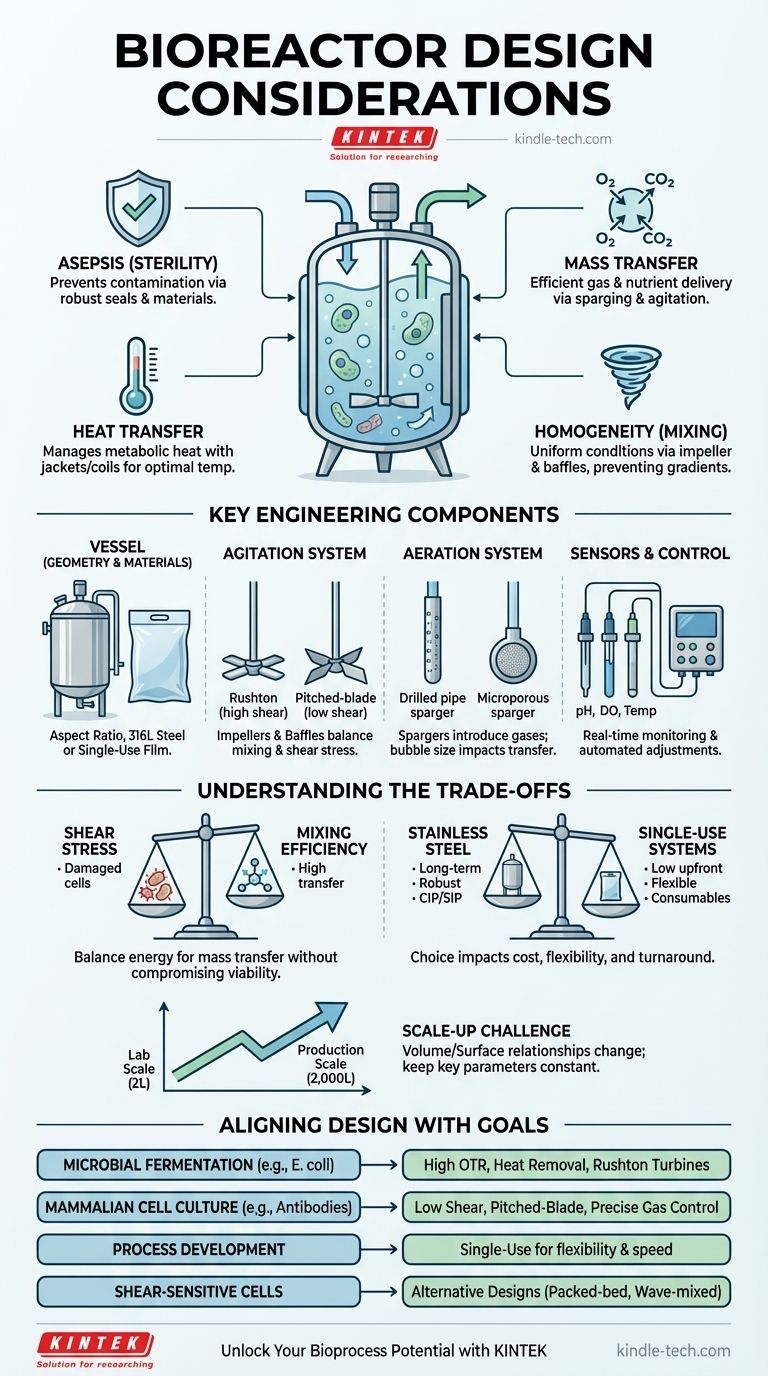

At its core, bioreactor design is the practice of creating a precisely controlled and sterile environment that caters to the specific metabolic needs of living cells or microorganisms. Success hinges on a small set of fundamental principles: maintaining sterility (asepsis), enabling efficient mass transfer of gases and nutrients, managing heat, ensuring homogeneity through mixing, and implementing robust process monitoring and control. Every design choice, from the vessel's shape to the type of impeller, is a deliberate decision made to serve these biological requirements.

A bioreactor is not merely a container; it is an integrated system where the engineering must be entirely subservient to the biology. The fundamental challenge is to balance competing factors—such as mixing efficiency versus cell damage—to create the optimal conditions for your specific bioprocess.

The Foundation: Serving the Biological Process

Every design consideration stems from the need to create a stable and productive environment for the culture. The engineering components are simply the tools used to achieve these biological objectives.

Maintaining a Pure Culture (Asepsis)

Contamination is the single greatest threat to a successful bioprocess. An effective bioreactor design must be fundamentally sterile.

This is achieved through materials that can withstand sterilization (e.g., autoclaving or Steam-In-Place) and a design free of crevices where contaminants can hide. All connections, probes, and sampling ports must feature robust seals to prevent microbial ingress during the long duration of a culture.

Providing Oxygen and Nutrients (Mass Transfer)

Cells require a constant supply of oxygen and nutrients, and a constant removal of waste products like CO2. The design's ability to facilitate this exchange is a primary determinant of performance.

For aerobic cultures, the Oxygen Transfer Rate (OTR) of the reactor must meet or exceed the Oxygen Uptake Rate (OUR) of the cells. This is governed by the sparging system (which introduces gas bubbles) and the agitation system (which breaks up bubbles to increase surface area for gas exchange).

Controlling Temperature (Heat Transfer)

All biological processes generate heat. If this metabolic heat is not removed efficiently, the temperature will rise beyond the optimal range, stressing or killing the cells.

Bioreactors manage this with external jackets or internal cooling coils through which a cooling fluid is circulated. The efficiency of heat transfer depends on the surface area available for exchange and the overall design of the cooling system.

Achieving Homogeneity (Mixing)

The culture medium must be perfectly mixed to ensure every cell has equal access to nutrients and is not exposed to localized buildups of toxic byproducts. A lack of homogeneity creates performance-killing gradients in pH, dissolved oxygen, and substrate concentration.

Proper mixing is achieved through a combination of an optimized agitation system (impeller and motor) and internal vessel features like baffles, which prevent the formation of a central vortex and promote top-to-bottom fluid movement.

Key Engineering Components and Their Impact

With the biological goals established, we can examine the specific hardware components designed to meet them.

The Vessel Itself: Geometry and Materials

The shape and material of the reactor vessel have significant implications. The aspect ratio (height-to-diameter) influences mixing patterns and aeration efficiency, with taller, narrower vessels often used for microbial fermentation.

The material is typically 316L stainless steel for its durability and cleanability or, increasingly, single-use plastic films. The choice between them represents a major strategic decision in facility design and operational philosophy.

The Agitation System: Impellers and Baffles

The impeller is the heart of the mixing system. Its design dictates the balance between fluid movement and the physical force, or shear, exerted on the cells.

- Rushton turbines create high shear and are excellent for dispersing gas bubbles in robust microbial cultures.

- Pitched-blade or marine-style impellers generate gentle, axial flow ideal for fragile mammalian or insect cell cultures.

The Aeration System: Spargers and Gas Control

The sparger introduces gases into the reactor. A simple drilled-pipe or ring sparger releases larger bubbles suitable for many applications.

A microporous or sintered sparger creates much finer bubbles, dramatically increasing the surface area for oxygen transfer, but can be prone to clogging and can generate foam.

The "Nervous System": Sensors and Control

You cannot control what you cannot measure. A modern bioreactor is equipped with a suite of sensors to monitor critical process parameters in real-time.

Standard probes include those for pH, dissolved oxygen (DO), and temperature. This data is fed to a control unit that automatically adjusts inputs—such as adding a base to correct pH or increasing gas flow to raise DO—to keep the process within its optimal window.

Understanding the Trade-offs

Bioreactor design is an exercise in balancing competing requirements. Understanding these trade-offs is what separates a novice from an expert.

Shear Stress vs. Mixing Efficiency

This is the classic dilemma. Increasing impeller speed improves mixing and oxygen transfer, which is necessary for high-density cultures. However, this also increases shear stress, which can damage or kill fragile mammalian cells. The design must provide just enough energy for mass transfer without compromising cell viability.

Stainless Steel vs. Single-Use Systems

Stainless steel reactors are a long-term capital investment. They are robust and can be used for decades, but require significant infrastructure for cleaning (Clean-In-Place) and sterilization (Steam-In-Place), along with lengthy validation and turnaround times.

Single-Use Bioreactors (SUBs) have a much lower upfront cost and offer operational flexibility with near-zero turnaround time, as the entire product-contact component is disposed of after use. However, they carry recurring consumable costs and concerns about compounds leaching from the plastic into the medium.

The Challenge of Scale-Up

A process that works perfectly in a 2L benchtop reactor may fail completely in a 2,000L production vessel. This is because the relationships between volume, surface area, and mixing dynamics do not scale linearly.

Successful scale-up requires keeping a key parameter constant, such as impeller tip speed (to manage shear) or power per unit volume (to maintain mixing), forcing other design elements to change.

Aligning Design with Your Bioprocess Goal

The right design is the one that best serves your specific application. Use these guidelines to inform your thinking.

- If your primary focus is high-density microbial fermentation (e.g., E. coli): Prioritize a robust design with extremely high oxygen transfer and heat removal capacity, likely using Rushton turbines and a powerful cooling jacket.

- If your primary focus is large-scale mammalian cell culture (e.g., antibodies): Choose a system designed for low shear, using pitched-blade or other specialized impellers, and sophisticated gas control strategies for precise pH and DO management.

- If your primary focus is process development and flexibility: A single-use platform is often superior, as it allows you to quickly run different processes and cell lines without the risk of cross-contamination or the downtime of cleaning cycles.

- If your primary focus is cultivating shear-sensitive or anchorage-dependent cells: Consider alternative designs like packed-bed, hollow-fiber, or wave-mixed bioreactors that provide high surface area without mechanical agitation.

Ultimately, a well-designed bioreactor is an elegant solution to a complex biological challenge, engineered to unlock the full potential of your process.

Summary Table:

| Design Consideration | Key Factor | Impact on Process |

|---|---|---|

| Sterility (Asepsis) | Materials, seals, sterilization methods | Prevents contamination, ensures culture purity |

| Mass Transfer | Sparger type, impeller design, OTR | Delivers oxygen/nutrients, removes waste |

| Mixing & Homogeneity | Impeller type, baffles, agitation speed | Prevents gradients, ensures uniform conditions |

| Heat Transfer | Cooling jackets/coils | Maintains optimal temperature for cell growth |

| Scale-Up | Impeller tip speed, power/volume | Ensures process consistency from lab to production |

| Vessel Type | Stainless steel vs. single-use | Balances cost, flexibility, and operational needs |

Unlock the Full Potential of Your Bioprocess with KINTEK

Designing the right bioreactor system is critical to the success of your cell culture, fermentation, or bioprocessing workflow. The balance between sterility, efficient mass transfer, and gentle mixing is complex, and the wrong equipment can lead to costly failures and reduced yields.

KINTEK specializes in providing high-quality lab equipment and consumables tailored to the precise needs of modern laboratories. Whether you are scaling up a microbial fermentation process or cultivating sensitive mammalian cells for therapeutic production, we have the expertise and products to support you.

- Expert Guidance: Our team can help you navigate the trade-offs between stainless steel and single-use systems, or select the ideal impeller and sparger design for your specific cell line.

- Reliable Performance: Trust our equipment for robust temperature control, precise gas management, and consistent, reproducible results.

- Process Flexibility: From benchtop R&D to pilot-scale production, find the right bioreactor solution to accelerate your development timeline.

Don't let equipment limitations hinder your innovation. Contact our experts today to discuss how KINTEK's bioreactor solutions can enhance your lab's efficiency, reliability, and yield.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High Performance Laboratory Freeze Dryer for Research and Development

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is the role of high-pressure reactors in hydrothermal synthesis of CeO2? Optimize Nanocatalyst Morphology

- How do you choose an agitator in a reactor? Match Impeller Type to Your Process Goal

- How do magnetic stirring systems influence the reaction kinetics of lithium minerals? Maximize Your Leaching Yields

- Why is a corrosion-resistant reactor essential for alumina recovery from red mud? Optimize Your Acid Leaching Process

- How does a high-pressure reactor facilitate the solvothermal synthesis? Master Supercritical Material Engineering

- Why does the design of supercritical fluid electrochemical autoclaves use a nickel-base shell and a titanium liner?

- What are the advantages of stirred tank reactors? Achieve Unmatched Process Control and Uniformity

- How do the preheater and test chamber in a steam corrosion test system work together? Master High-Temp Simulation