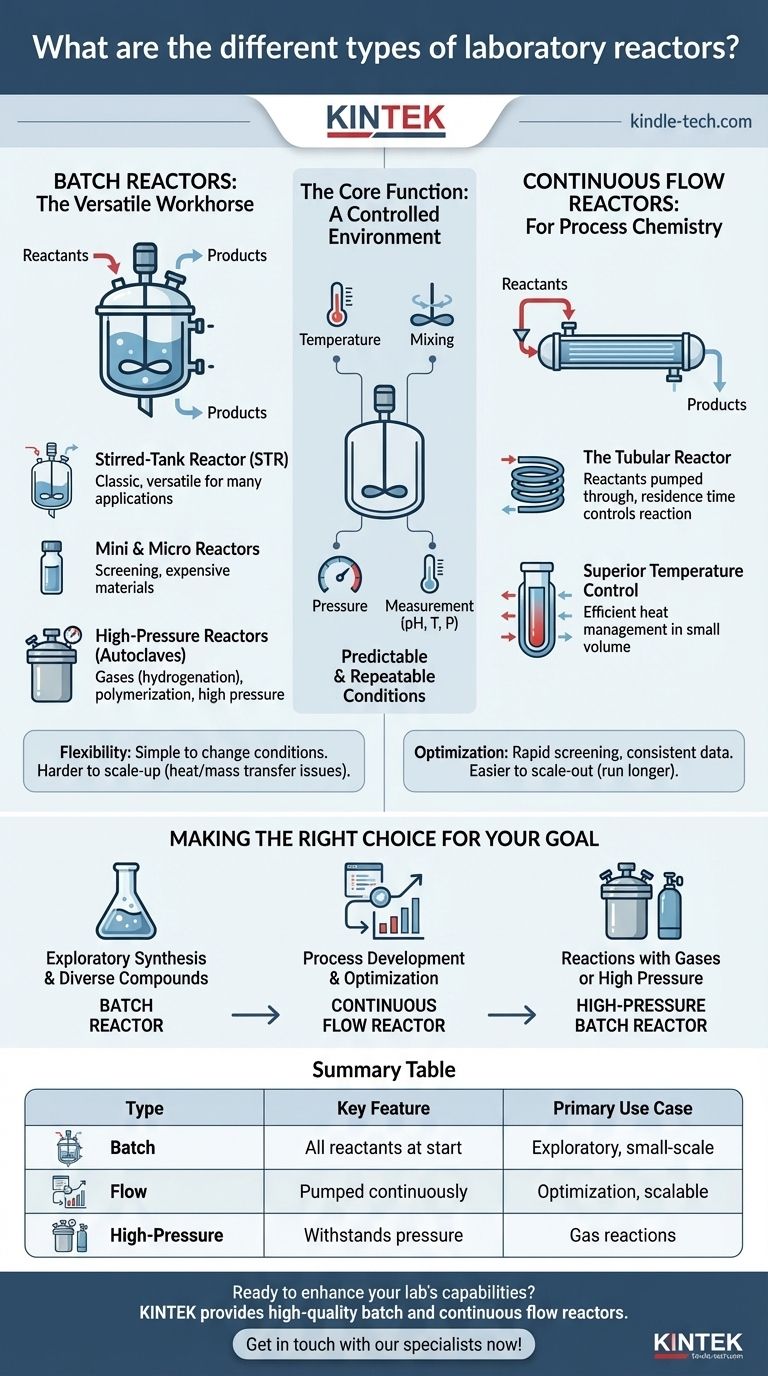

The primary types of laboratory reactors are batch reactors (like stirred-tank and high-pressure vessels) and continuous flow reactors (like tubular systems). Each is designed to provide a highly controlled environment for chemical reactions, but they operate on fundamentally different principles suited for different research and development goals.

The choice of a laboratory reactor is not about finding the "best" overall option. It's about matching the reactor's design—batch for versatility, continuous for process control—to the specific goals of your chemical synthesis or analysis.

The Core Function: A Controlled Environment

Before comparing types, it's crucial to understand what all lab reactors aim to achieve. Their fundamental purpose is to create a predictable and repeatable environment for a chemical reaction.

Controlling Reaction Variables

A reactor gives you precise command over the conditions that govern a reaction's outcome. This includes the temperature of the vessel, the degree of mixing or agitation, and the internal pressure.

Measuring Key Parameters

Modern reactors are equipped with probes and sensors to monitor the reaction in real time. This allows for the precise measurement of parameters like pH, temperature, and pressure, providing critical data for analysis and optimization.

Batch Reactors: The Versatile Workhorse

Batch reactors are the most common type found in research labs. The core principle is simple: all reactants are added to a vessel at the start, the reaction proceeds, and the products are removed at the end.

The Stirred-Tank Reactor (STR)

This is the classic lab reactor. It consists of a vessel, a stirring mechanism (like an overhead stirrer with an impeller), and ports for adding reagents, taking samples, and inserting probes. Its versatility makes it ideal for a wide range of applications.

Mini and Micro Reactors

These are simply scaled-down versions of the STR. They are used for reaction screening, working with very expensive or potent materials, or when only a small quantity of product is needed.

High-Pressure Reactors (Autoclaves)

An autoclave is a specialized type of batch reactor built from robust materials (like steel or Hastelloy) to withstand high internal pressures. They are essential for reactions involving gases like hydrogen (hydrogenation) or for certain types of polymerization.

Continuous Flow Reactors: For Process Chemistry

In a continuous flow system, reactants are constantly pumped into and through the reactor, where they mix and react. The product stream flows out continuously for collection.

The Tubular Reactor

This is a common type of flow reactor where reactants are pumped through a tube. The tube itself is the reactor volume, and its length and diameter determine the residence time (how long the reactants spend reacting).

Superior Temperature Control

Flow reactors excel at thermal management. Because the reaction occurs in a small-volume tube, heat can be added or removed very efficiently. This is often done with an external heating element or by encasing the tube in a jacket filled with a circulating heating or cooling fluid.

Understanding the Trade-offs: Batch vs. Flow

Choosing between a batch and a continuous flow reactor involves clear trade-offs tied directly to your research goals.

Flexibility vs. Optimization

Batch reactors are highly flexible. It's simple to change reagents, solvents, and conditions from one experiment to the next, making them perfect for discovery chemistry and early-stage research.

Flow reactors are built for optimization. While the initial setup can be more complex, they allow for rapid screening of conditions like temperature and residence time, providing rich data sets for process development.

Scalability and Consistency

Scaling up a batch reaction can be challenging because heat and mass transfer do not scale linearly. A reaction that is safe in a 1L flask might become dangerously uncontrollable in a 100L vessel.

Continuous flow reactors are much easier to scale. To produce more material, you simply run the system for a longer period. This "scale-out" approach provides a more consistent product and a direct model for industrial production.

Making the Right Choice for Your Goal

Your specific objective dictates which reactor architecture is the most appropriate and effective tool for the job.

- If your primary focus is exploratory synthesis or creating small amounts of diverse compounds: A stirred-tank batch reactor provides the greatest operational flexibility.

- If your primary focus is process development, reaction optimization, or kinetic studies: A continuous flow reactor offers superior control, consistency, and data quality.

- If your primary focus is running reactions with gases or under high-pressure conditions: A specialized high-pressure batch reactor (autoclave) is the essential and safe choice.

Ultimately, understanding these fundamental designs empowers you to select the reactor that will generate the most precise, repeatable, and scalable results for your work.

Summary Table:

| Reactor Type | Key Feature | Primary Use Case |

|---|---|---|

| Batch Reactor | All reactants added at start; versatile | Exploratory synthesis, small-scale production |

| Continuous Flow Reactor | Reactants pumped through continuously | Process optimization, kinetic studies, scalable production |

| High-Pressure Reactor (Autoclave) | Withstands high internal pressure | Reactions with gases (e.g., hydrogenation), high-pressure synthesis |

Ready to enhance your lab's capabilities?

The right laboratory reactor is key to achieving precise, repeatable, and scalable results. KINTEK specializes in providing high-quality lab equipment, including a comprehensive range of batch and continuous flow reactors, to meet your specific research and development needs.

Our experts can help you select the ideal reactor for your chemical synthesis or process optimization goals. Contact us today to discuss your application and discover how our solutions can drive your success.

Get in touch with our specialists now!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the safety considerations of high-pressure vessels in nanopowder synthesis? Mastering Force and Containment

- What is the primary purpose of a stirred reactor? Mastering Chemical Reactions with Precision

- Why must stainless steel reactors be utilized for CFRP alkali fusion? Ensuring Safety in Harsh Chemical Environments

- What is the function of a high-pressure stainless steel reactor in PWR corrosion tests? Expert Simulation Guide

- What are the requirements for PVC pyrolysis reactor corrosion resistance? Expert Material Guide

- What is the use of a pyrolysis reactor? Transform Waste into Valuable Biofuels and Chemicals

- Why is it necessary to equip HTL reactors with corrosion-resistant alloy liners? Protect Your Data and Equipment

- Why must SCWG reactors maintain a specific heating rate? Protect Your High-Pressure Vessels from Thermal Stress