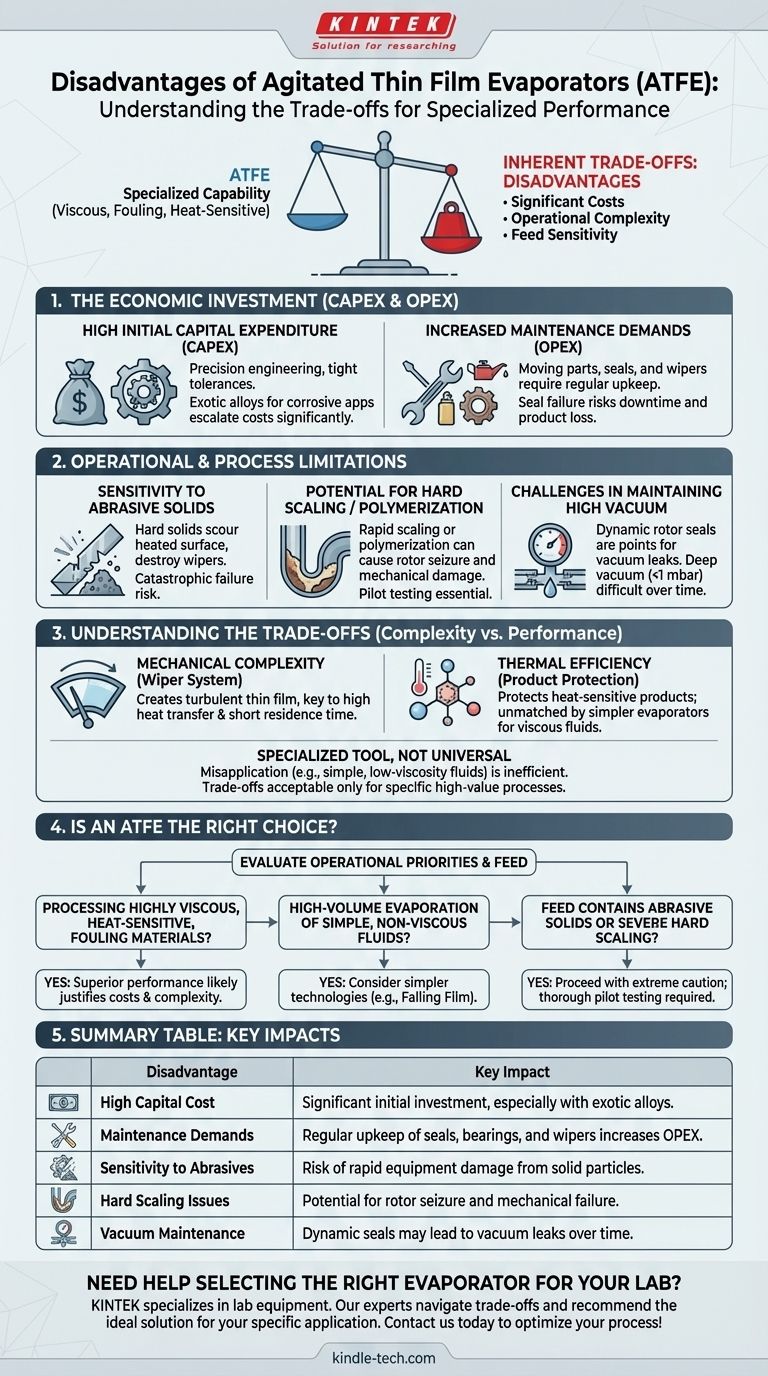

While highly effective for specific applications, an agitated thin film evaporator (ATFE) is not a universal solution. Its primary disadvantages are significant capital and maintenance costs, operational complexity due to its mechanical nature, and a critical sensitivity to certain feed characteristics, such as the presence of abrasive solids or materials that cause hard scaling.

The disadvantages of an ATFE are not design flaws but inherent trade-offs for its specialized capability. The high cost and mechanical complexity are the price for its unique ability to process highly viscous, fouling, and heat-sensitive products with exceptional efficiency.

The Economic Investment: Capital and Operational Costs

The most immediate barrier to adopting ATFE technology is often financial. Both the initial purchase and the long-term upkeep demand significant investment compared to simpler, static evaporator designs.

High Initial Capital Expenditure (CAPEX)

An ATFE is a precision-engineered piece of equipment. The internal rotor, wipers, and the meticulously machined evaporator body require tight tolerances, driving up manufacturing costs.

When exotic alloys are required for corrosive applications, these costs escalate substantially more than they would for a simpler vessel like a falling film evaporator.

Increased Maintenance Demands

Unlike static evaporators, an ATFE has moving parts that are subject to wear and tear. The rotor bearings and, most critically, the mechanical seals are regular maintenance items.

Seal failure can lead to loss of vacuum and product contamination, resulting in costly operational downtime. Wipers also need periodic inspection and replacement, adding to the long-term operational expenditure (OPEX).

Operational and Process Limitations

Beyond the cost, an ATFE presents specific operational challenges and is unsuitable for certain process conditions. Understanding these limitations is critical to avoid costly misapplication of the technology.

Sensitivity to Abrasive Solids

The core of an ATFE's design is the small, precise clearance between the wiper blades and the heated wall. Introducing a feed stream with hard, abrasive solids can quickly lead to catastrophic failure.

These solids can get trapped in the clearance, scouring the heated surface and destroying the wipers. This damage is expensive to repair and severely compromises the evaporator's performance.

Potential for Hard Scaling or Polymerization

While excellent for many fouling materials, an ATFE can struggle with substances that form extremely hard scale or polymerize rapidly on the heated surface.

If the scale builds to a point where it cannot be removed by the wipers, it can cause the rotor to seize, leading to major mechanical damage. Pilot testing is essential to verify compatibility.

Challenges in Maintaining High Vacuum

The rotating shaft of the rotor must pass through a seal in the evaporator body. This dynamic seal is a common point for vacuum leaks, especially as it wears over time.

Achieving and maintaining a very deep vacuum (below 1 mbar) can be more challenging in an ATFE compared to a static system that relies only on stationary gaskets.

Understanding the Trade-offs

The disadvantages of an ATFE must be weighed against its unique processing capabilities. The decision to use one is always a matter of balancing complexity against performance needs.

Mechanical Complexity vs. Thermal Efficiency

The very component that creates complexity—the rotating wiper system—is what enables the ATFE's key advantages.

The wipers create a turbulent, thin film that achieves very high heat transfer coefficients and minimizes residence time. This protects heat-sensitive products from thermal degradation, a feat that simpler evaporators cannot match for viscous fluids.

Specialized Tool, Not a Universal Solution

Using an ATFE for a simple, low-viscosity, non-heat-sensitive application (like concentrating sugar water) would be a mistake. A much cheaper and simpler falling film or forced circulation evaporator would be more appropriate.

The ATFE's disadvantages are only truly "disadvantages" when the technology is misaligned with the processing goal. For the right application, they are necessary and acceptable trade-offs.

Is an ATFE the Right Choice for Your Process?

To make a definitive decision, evaluate the technology in the context of your specific operational priorities and feed characteristics.

- If your primary focus is processing highly viscous, heat-sensitive, or fouling materials: The superior performance and product protection offered by an ATFE will likely justify its costs and complexity.

- If your primary focus is high-volume evaporation of simple, non-viscous fluids: A less complex and less expensive technology like a multi-effect or falling film evaporator is a more economical and practical choice.

- If your feed stream contains abrasive solids or has severe, hard-scaling tendencies: You must proceed with extreme caution and conduct thorough pilot testing to avoid rapid and severe equipment damage.

Understanding these disadvantages is the first step toward selecting the most effective and economical technology for your specific goal.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Capital Cost | Significant initial investment, especially with exotic alloys |

| Maintenance Demands | Regular upkeep of seals, bearings, and wipers increases OPEX |

| Sensitivity to Abrasives | Risk of rapid equipment damage from solid particles |

| Hard Scaling Issues | Potential for rotor seizure and mechanical failure |

| Vacuum Maintenance | Dynamic seals may lead to vacuum leaks over time |

Need help selecting the right evaporator for your lab? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the trade-offs of agitated thin film evaporators and recommend the ideal solution for your specific application—whether you're processing viscous, heat-sensitive materials or require a more economical alternative. Contact us today to optimize your evaporation process and maximize efficiency!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Tungsten Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is vacuum thermal evaporation? A Guide to High-Purity Thin Film Deposition

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications