The primary disadvantages of blown film extrusion are its difficulty in achieving precise thickness control, its overall process complexity, and its slower production rates compared to alternative methods like cast film extrusion. These limitations stem from the inherent nature of using air pressure to inflate a molten polymer tube, which introduces numerous variables that can be challenging to manage.

While excellent for creating seamless tubing with balanced mechanical properties, the blown film process trades precision and speed for this unique capability. The core challenges are rooted in the physics of air-cooling and expanding a molten polymer bubble uniformly.

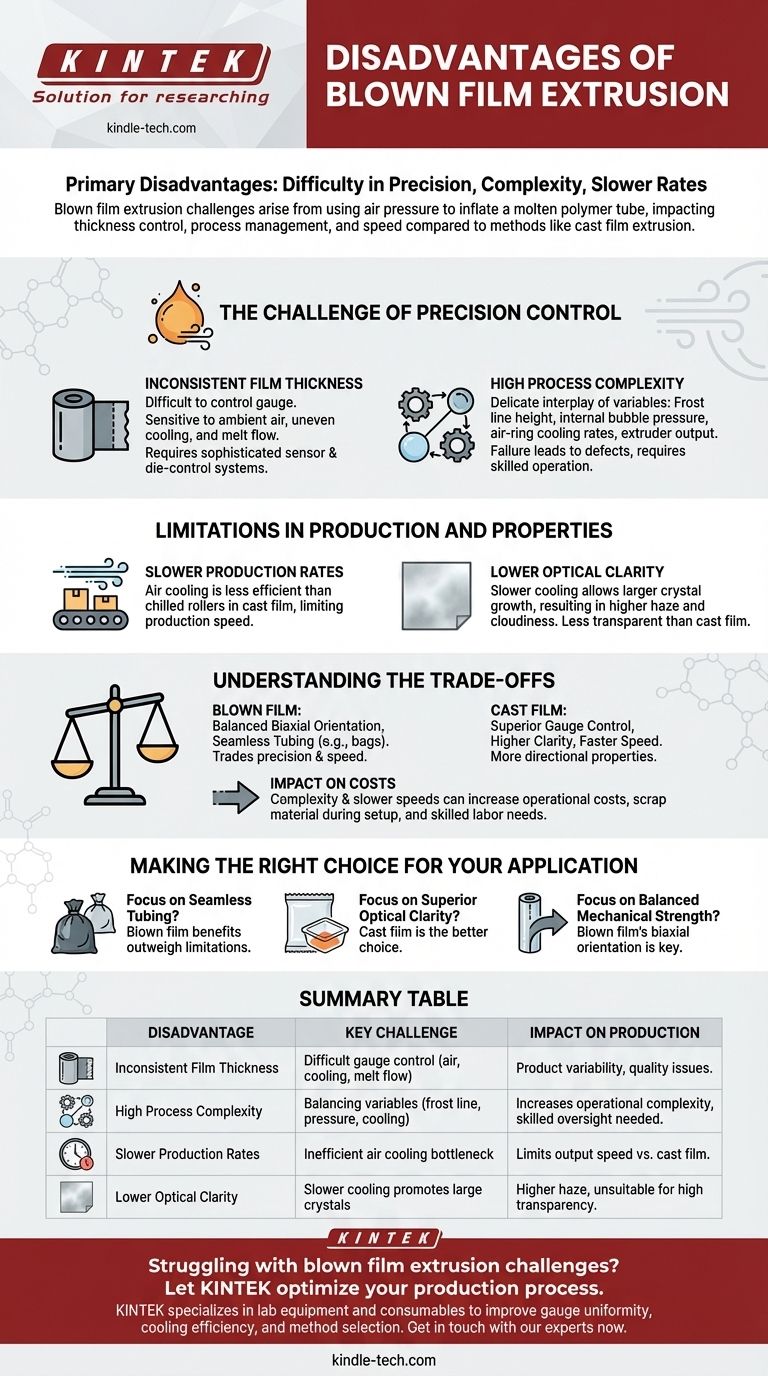

The Challenge of Precision Control

The most significant operational drawbacks of blown film extrusion relate to maintaining tight tolerances and process stability. Small variations can have a cascading effect on the final product quality.

Inconsistent Film Thickness

Controlling the gauge (thickness) of the film is notoriously difficult. The expansion of the molten bubble is sensitive to ambient air currents, inconsistent polymer melt flow, and uneven cooling, leading to thicker or thinner spots in the film.

Achieving uniform thickness requires sophisticated sensor and die-control systems, adding cost and complexity to the production line.

High Process Complexity

The blown film process involves managing a delicate interplay of multiple variables. Factors like frost line height, internal bubble pressure, air-ring cooling rates, and extruder output must be perfectly balanced.

A failure to control any one of these elements can lead to bubble instability, wrinkles, or other defects, requiring skilled operators to manage effectively.

Limitations in Production and Properties

Beyond process control, blown film has inherent limitations regarding its output speed and the optical qualities of the resulting film. These factors are critical when comparing it to other manufacturing methods.

Slower Production Rates

The manufacturing rates for blown film are significantly lower than for cast film. This is primarily due to the cooling process.

Air cooling is far less efficient than the chilled rollers used in cast film extrusion. This cooling bottleneck limits how fast the line can run while still producing stable, high-quality film.

Lower Optical Clarity

Blown film generally has lower clarity and higher haze levels compared to cast film. The slower air-cooling process allows more time for polymer crystals to form and grow larger.

These larger crystal structures scatter more light, making the film appear cloudier, which is undesirable for applications requiring high transparency.

Understanding the Trade-offs

Choosing a film manufacturing process requires an objective look at the compromises involved. The disadvantages of blown film are the direct trade-offs for its unique advantages.

Blown Film vs. Cast Film

The central trade-off is often between blown film and cast film. Blown film provides balanced, biaxial orientation (strength in both machine and transverse directions) and creates seamless tubes ideal for bags.

In contrast, cast film offers superior gauge control, higher clarity, and much faster production speeds, but with properties that are more directional.

Impact on Costs

The complexity and slower speeds can lead to higher operational costs. Initial setup can generate more scrap material while dialing in the process parameters, and the need for more skilled oversight can increase labor costs.

Making the Right Choice for Your Application

Ultimately, the "disadvantages" of blown film are only disadvantages if they conflict with your product's primary requirements.

- If your primary focus is cost-effective production of seamless tubing (e.g., trash bags or construction sheeting): The benefits of the process far outweigh its limitations in precision control.

- If your primary focus is superior optical clarity and uniform thickness (e.g., high-end food packaging or laminating films): The inherent drawbacks of blown film make cast film the more logical and efficient choice.

- If your primary focus is balanced mechanical strength for applications like shrink wrap: Blown film's biaxial orientation is a key advantage, and managing its process complexity is a necessary investment.

Selecting the correct manufacturing method begins with a clear understanding of your final product's most critical requirements.

Summary Table:

| Disadvantage | Key Challenge | Impact on Production |

|---|---|---|

| Inconsistent Film Thickness | Difficult to control gauge due to air currents, uneven cooling, and melt flow variations. | Leads to product variability and potential quality issues. |

| High Process Complexity | Requires balancing multiple variables like frost line height, bubble pressure, and cooling rates. | Increases operational complexity and requires skilled oversight. |

| Slower Production Rates | Air cooling is less efficient than cast film's chilled rollers, creating a bottleneck. | Limits output speed compared to cast film extrusion. |

| Lower Optical Clarity | Slower cooling promotes larger crystal formation, resulting in higher haze and cloudiness. | Unsuitable for applications requiring high transparency. |

Struggling with blown film extrusion challenges? Let KINTEK optimize your production process.

As specialists in lab equipment and consumables, KINTEK understands the precise demands of polymer processing. Whether you're troubleshooting gauge uniformity, improving cooling efficiency, or selecting the right method for your application, our expertise and high-quality solutions can help you overcome the limitations of blown film extrusion.

Contact us today to discuss how we can enhance your film manufacturing efficiency and product quality.

Get in touch with our experts now

Visual Guide

Related Products

People Also Ask

- What is a 3 hi rolling mill? A Guide to Efficient Bidirectional Metal Shaping

- What is injection molding in simple words? A Simple Guide to Mass-Producing Parts

- What is the difference between extrusion and co-extrusion? Engineer Multi-Material Parts

- What is a laboratory mixer used for? Choose the Right Tool for Liquids or Solids

- What are the ingredients used in rubber compounding? A Guide to the Essential Formula

- What are the three types of rolling mills? A Guide to Boosting Your Metal Production Efficiency

- What size are injection molding machines? Match Tonnage to Your Part for Quality & Efficiency

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?