To use an autoclave safely and effectively, you must treat it as a controlled system of high-pressure steam. The most important rules are to always ensure you are properly trained for your specific model and to verify that all materials you place inside are autoclave-safe. Critically, you must never autoclave sealed liquid containers and never attempt to open the door until the cycle is complete and the chamber pressure has returned to a safe level.

The autoclave works on a simple principle: moist heat (steam) under high pressure is exceptionally effective at sterilization. Your success and safety depend entirely on ensuring this steam can penetrate every surface and that you respect the immense pressure within the chamber by never bypassing safety protocols.

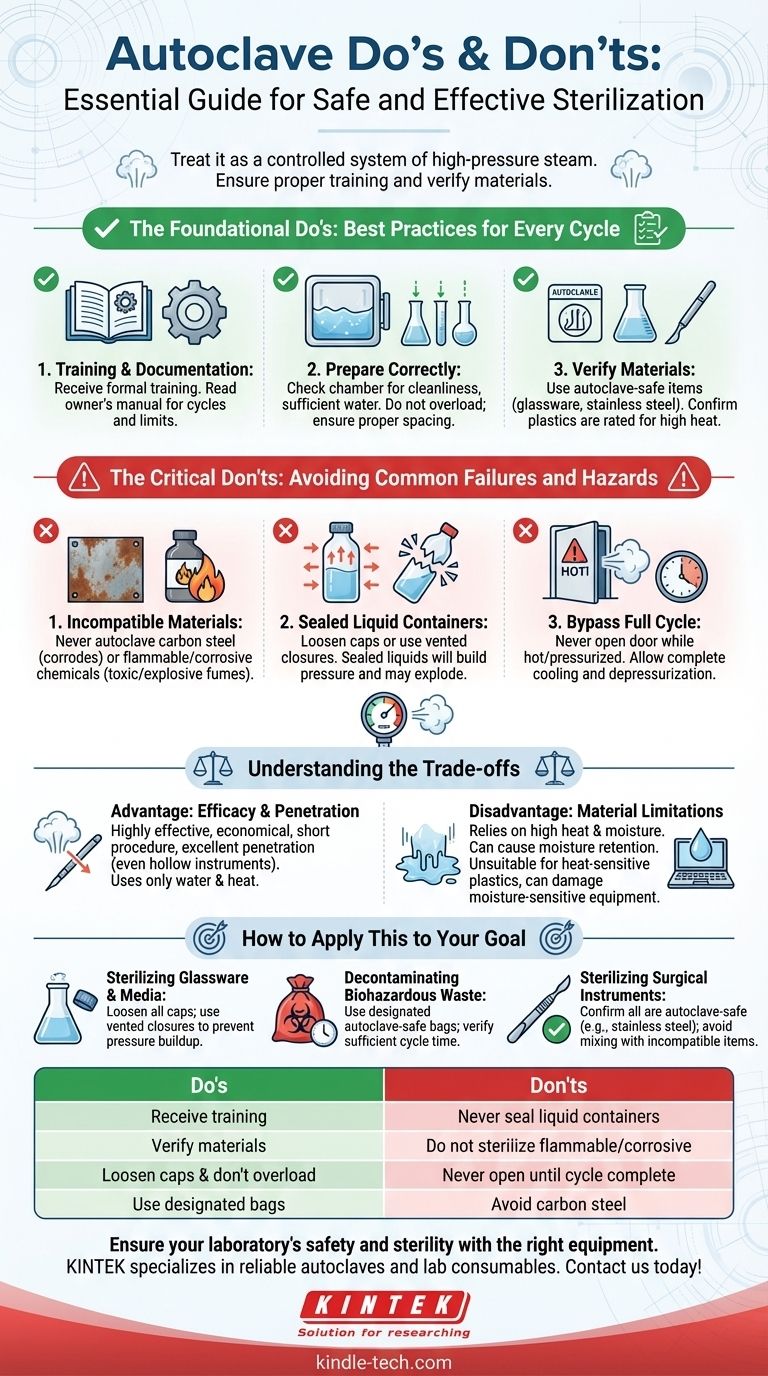

The Foundational "Do's": Best Practices for Every Cycle

Proper autoclave use is a matter of preparation and process. Following these steps ensures both effective sterilization and safe operation for every cycle you run.

Always Start with Training and Documentation

Every operator must receive formal training on the specific autoclave model they will be using. Before your first use, read and understand the manufacturer's owner's manual.

This documentation contains critical information about your machine's specific sterilization cycles, temperature settings, and pressure limits.

Prepare the Chamber and Your Load Correctly

Before loading, check the chamber to ensure no materials have been left over from a previous run. The interior should be clean, and you must verify there is a sufficient amount of water to generate steam for the entire cycle.

When placing items inside, do not overload the chamber. Proper spacing is essential to allow steam to circulate and penetrate all surfaces for effective sterilization.

Verify Materials are Autoclave-Safe

An autoclave is the correct tool for sterilizing items like laboratory glassware, media, solutions, stainless steel instruments, and other heat-resistant accessories.

Always confirm that any plastics are rated for autoclaving, as materials not designed to withstand the high heat and pressure will melt, causing damage and failed sterilization.

The Critical "Don'ts": Avoiding Common Failures and Hazards

Violating autoclave protocols can lead to failed sterilization, damage to equipment, or severe personal injury. These "don'ts" are non-negotiable rules.

Never Autoclave Incompatible Materials

Certain items must be kept out of an autoclave. This includes materials that can be damaged by moisture, such as carbon steel, which is prone to corrosion.

Do not sterilize flammable, volatile, or corrosive chemicals. The high heat can cause these substances to produce toxic or explosive fumes.

Do Not Seal Liquid Containers

When autoclaving liquids like media or buffers, you must loosen the caps or use vented closures.

Heating a liquid in a sealed container will cause a massive pressure buildup, creating a significant risk of the container shattering or exploding upon opening.

Never Bypass the Full Cycle

The sterilization process includes the heating, sterilizing, and cool-down phases. You must allow the machine to complete its full cycle, including cooling and depressurization.

Attempting to open the door while the chamber is still hot and pressurized is the single most dangerous mistake an operator can make, risking severe burns from the explosive release of high-pressure steam.

Understanding the Trade-offs

Like any technology, autoclaving has distinct advantages and limitations that determine when it is the appropriate choice for sterilization.

The Advantage: Efficacy and Penetration

Moist heat sterilization is highly effective and economical. It has a relatively short procedure time compared to other methods and provides excellent penetration on all surfaces, including those of hollow or irregularly shaped instruments.

Furthermore, it relies only on water and heat, avoiding the need for additional chemicals or disposables.

The Disadvantage: Material Limitations

The primary drawback is its reliance on high heat and moisture. This process can cause moisture retention on sterilized items, which may be undesirable for certain applications.

More importantly, it restricts the types of materials that can be processed. It is unsuitable for heat-sensitive plastics and can cause damage to moisture-sensitive equipment.

How to Apply This to Your Goal

Your specific objective dictates your key areas of focus when operating an autoclave.

- If your primary focus is sterilizing laboratory glassware and media: Ensure you loosen all caps and use vented closures to prevent pressure buildup and potential explosions.

- If your primary focus is decontaminating biohazardous waste: Use designated autoclave-safe bags and verify the cycle time is sufficient for complete steam penetration and sterilization of the entire load.

- If your primary focus is sterilizing surgical instruments: Confirm that all instruments are made of autoclave-safe materials like stainless steel and avoid mixing them with incompatible items like carbon steel.

Following these principles transforms the autoclave from a potential hazard into an indispensable tool for guaranteed sterility.

Summary Table:

| Do's | Don'ts |

|---|---|

| Receive formal training for your specific model | Never autoclave sealed liquid containers |

| Verify all materials are autoclave-safe | Do not sterilize flammable or corrosive chemicals |

| Loosen caps on liquids and do not overload the chamber | Never open the door until the cycle is complete and depressurized |

| Use designated autoclave-safe bags for biohazardous waste | Avoid materials like carbon steel that can corrode |

Ensure your laboratory's safety and sterility with the right equipment. KINTEK specializes in providing reliable autoclaves and lab consumables designed for effective sterilization. Our experts can help you select the perfect autoclave for your specific needs, whether you're processing glassware, media, or biohazardous waste. Contact us today to learn more about our products and how we can support your laboratory's success!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the necessity of using a steam autoclave for dental alloys? Ensure Pure Bacterial Adhesion Data