For an autoclave to be effective, four factors must be perfectly aligned: time, temperature, pressure, and direct steam contact. The successful sterilization of any item is not merely a function of the machine's settings; it is critically dependent on the proper preparation and loading of the materials to ensure that pressurized, high-temperature steam can reach every surface.

The core principle of autoclave sterilization is that its success is determined as much by user preparation as it is by the machine's cycle. Without proper cleaning, loading, and cycle selection, even the most advanced autoclave will fail to achieve sterility.

The Core Principles of Autoclave Sterilization

An autoclave is not simply a high-heat oven. It uses the physical properties of steam under pressure to destroy microorganisms far more efficiently than dry heat alone.

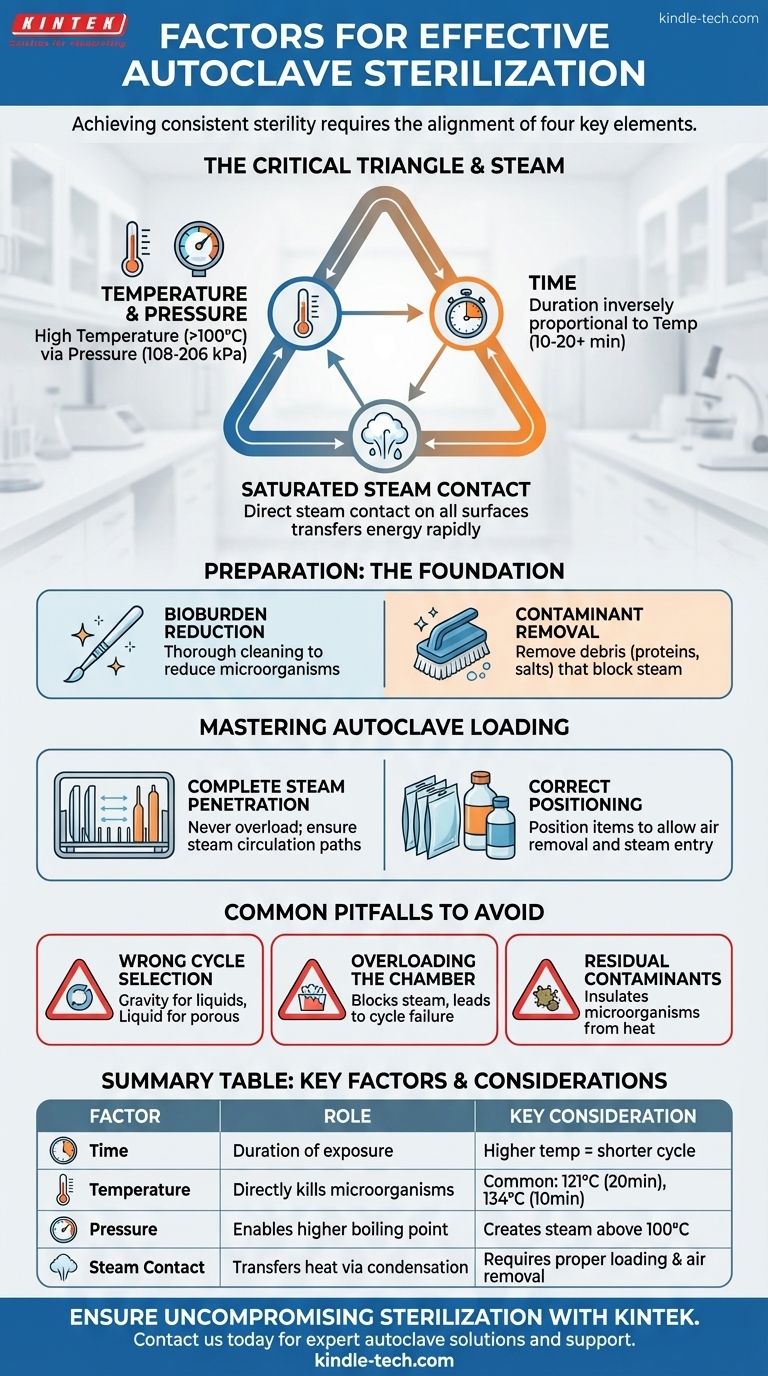

Time, Temperature, and Pressure: The Critical Triangle

The effectiveness of sterilization is a function of temperature and the duration of exposure. By increasing the pressure inside its chamber, an autoclave forces water to boil at temperatures far above 100°C (212°F).

This relationship is inversely proportional to time. Higher temperatures, achieved through higher pressure, can sterilize items more quickly.

For example, a common cycle runs at 121°C (250°F) under approximately 108 kPa (15.5 PSI) of pressure for 20 minutes. A faster cycle might run at 134°C (273°F) under 206 kPa (29.8 PSI) for as little as 10 minutes.

The Essential Role of Saturated Steam

The true sterilization agent in an autoclave is saturated steam. When this high-temperature steam makes direct contact with a cooler item, it immediately condenses into water, rapidly transferring a massive amount of thermal energy.

This energy transfer is what denatures the proteins and enzymes essential for a microorganism's survival, ensuring its destruction. If steam cannot make direct contact, this process fails.

Preparation: The Foundation of Effective Sterilization

What you do before you even open the autoclave door is one of the most significant factors in a successful cycle. The goal is to remove any barrier between the steam and the microorganisms.

The Problem of Bioburden

Bioburden refers to the total number of microorganisms on a surface prior to sterilization. Instruments must be thoroughly cleaned to reduce this load.

While an autoclave is designed to kill microorganisms, a high initial bioburden can challenge the process and requires longer, more robust cycles to ensure complete sterility.

Removing Residual Contaminants

Any residual debris, especially proteins and salts, can act as an insulating barrier, shielding microorganisms from the steam.

Even a microscopic layer of dried protein or salt can prevent the direct steam contact necessary for effective heat transfer, potentially allowing organisms to survive the cycle.

Mastering Autoclave Loading

How you arrange items inside the chamber directly impacts the flow of steam and the removal of air, which is the primary enemy of sterilization.

Ensuring Complete Steam Penetration

Never overload or clutter the autoclave chamber. Items packed too tightly will prevent steam from circulating freely, creating "cold spots" where the temperature never reaches the required level for sterilization.

Leave adequate space between all items to create pathways for steam to travel and for displaced air to escape.

Correct Positioning of Items

The orientation of objects is critical. Pouches should be placed on their edge in racks, and containers or bottles should be positioned to ensure steam can enter and displace the air within them.

Never lay pouches flat and stacked on top of one another, as this traps air and blocks steam penetration.

Separating Different Load Types

Avoid mixing different types of materials, such as clean glassware and biological waste, in the same cycle.

Different materials require different cycle parameters (e.g., liquid vs. solid cycles), and separating them prevents cross-contamination and ensures the correct cycle is used for each.

Common Pitfalls to Avoid

Mistakes in preparation or operation are the most common causes of sterilization failure. Understanding them is key to ensuring consistent results.

Choosing the Wrong Cycle

Selecting an inappropriate cycle is a frequent error. A "gravity" cycle designed for solids will cause liquids to boil over, while a "liquid" cycle is ineffective for dense, porous loads that require a vacuum stage to remove trapped air.

Using the wrong cycle can either damage the materials being sterilized or, more dangerously, result in a non-sterile load.

Overloading the Chamber

The most common pitfall is the belief that a fuller autoclave is a more efficient one. The opposite is true.

An overloaded chamber guarantees that steam will not reach all surfaces, leading to cycle failure. It is always better to run two properly loaded cycles than one overloaded one.

How to Apply This to Your Project

Your sterilization goal dictates your specific focus. Use these guidelines to ensure your autoclave procedure is effective for your needs.

- If your primary focus is sterilizing solid instruments (e.g., metal tools): Your priority is meticulous pre-cleaning to remove all bioburden and residual proteins.

- If your primary focus is sterilizing liquids (e.g., media): You must use a dedicated liquid cycle with a slow exhaust to prevent the container from boiling over or cracking.

- If your primary focus is sterilizing porous goods (e.g., surgical gowns): You must use a cycle with a pre-vacuum stage to ensure all air is removed and steam can fully penetrate the material.

- If your primary focus is decontaminating waste: Ensure you are using bags that allow for steam penetration and avoid overfilling them, which can trap air and shield waste from direct steam contact.

Ultimately, achieving consistent and reliable sterilization is a matter of respecting the process as a whole, from cleaning and preparation to final cycle selection.

Summary Table:

| Factor | Role in Sterilization | Key Consideration |

|---|---|---|

| Time | Duration of exposure to lethal conditions | Higher temperatures allow for shorter cycles |

| Temperature | Directly kills microorganisms | Common cycles: 121°C for 20 min or 134°C for 10 min |

| Pressure | Enables higher boiling point of water | Creates steam at temperatures above 100°C |

| Steam Contact | Transfers heat via condensation | Requires proper loading and air removal |

Ensure Your Lab's Sterilization is Uncompromising

Achieving consistent, reliable sterilization is critical for your lab's integrity and safety. KINTEK specializes in providing high-performance autoclaves and expert support to meet your specific laboratory needs—whether you're sterilizing instruments, media, porous goods, or waste.

Let our team help you select the right equipment and optimize your sterilization protocols. Contact KINTEK today to discuss how our lab equipment solutions can enhance your sterilization efficiency and ensure complete peace of mind.

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- How long are autoclaved instruments good for? The Truth About Sterility and Storage

- Why is autoclave temperature 121°C? The Science Behind Sterilization's Critical Point

- What is the capacity of an autoclave? Choose the Right Size for Your Sterilization Needs

- How does autoclave work inside? Mastering the Science of Steam Sterilization

- Is autoclave effective on all organisms? The Definitive Guide to Sterilization Limits

- Which autoclave is used in microbiology lab? Gravity Displacement vs. Pre-Vacuum Explained

- What is the application of retort machine in food industry? Ensuring Shelf-Stable Food Safety and Longevity

- What are the different types of autoclaves in microbiology? Gravity vs. Pre-Vacuum Explained