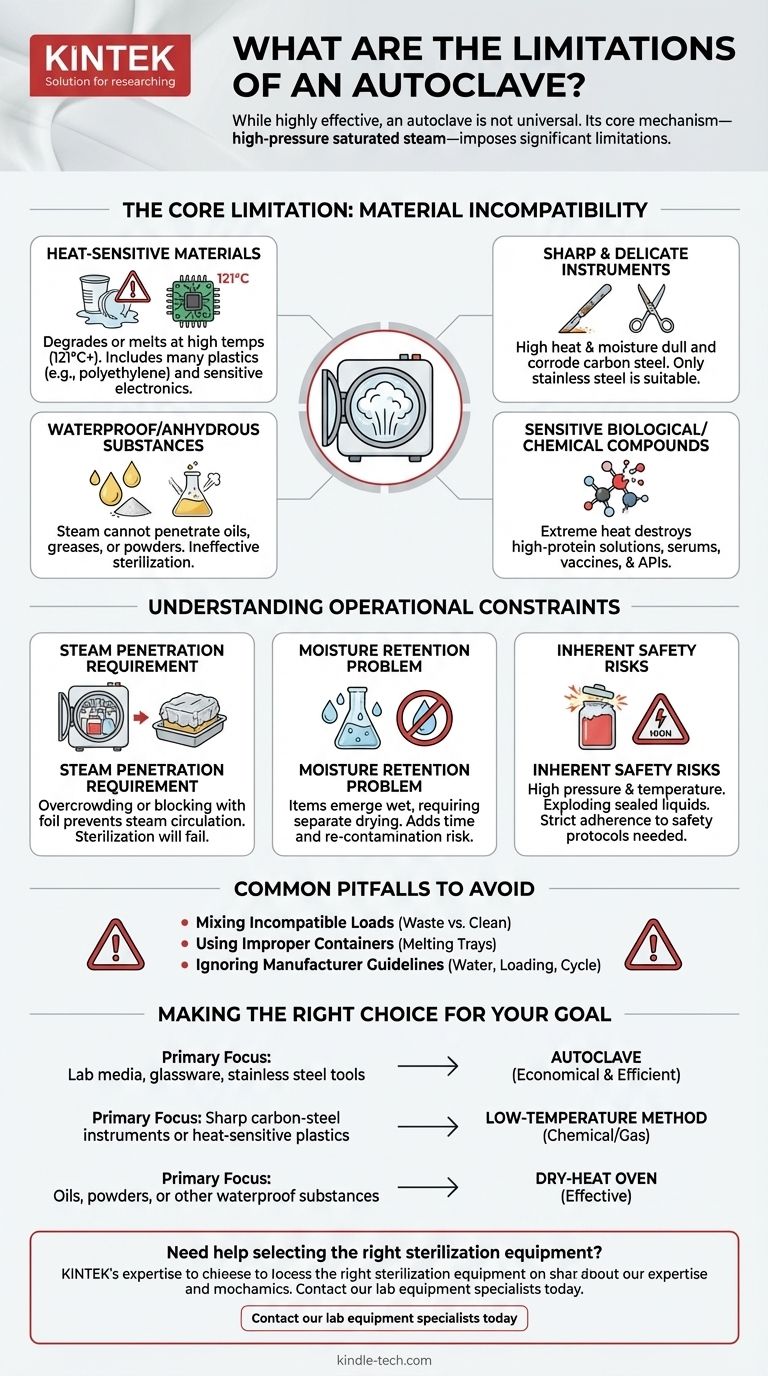

While highly effective for many applications, an autoclave is not a universal sterilizer. Its core mechanism—using high-pressure saturated steam—imposes significant limitations related to material compatibility. It cannot be used on items that are sensitive to heat and moisture, such as certain plastics, sharp carbon steel instruments, and waterproof substances like oils or powders.

The central limitation of an autoclave is its reliance on heat and steam. This makes it fundamentally incompatible with any material that can be damaged by high temperatures or moisture, requiring users to carefully match the sterilization method to the material being processed.

The Core Limitation: Material Incompatibility

An autoclave's effectiveness is confined to items that can withstand its intense environment. Several categories of materials are unsuitable for steam sterilization and can be damaged or left unsterilized.

Heat-Sensitive Materials

Many common materials degrade or melt under the typical autoclaving temperatures of 121°C (250°F) or higher.

This includes many types of plasticware, which can warp or melt, and sensitive electronics. Polyethylene, for instance, can melt and cause significant damage to the autoclave itself.

Sharp and Delicate Instruments

The combination of high heat and moisture is destructive to certain metals. Carbon steel, often used for high-grade scalpels and scissors, will become dull and corrode.

For this reason, only instruments specifically rated for autoclaving, typically made of stainless steel, should be processed this way.

Waterproof or Anhydrous Substances

Steam sterilization works by direct steam contact condensing on an item. This process is ineffective for substances that do not mix with water.

This makes autoclaves unsuitable for sterilizing oils, greases, or powders. Steam cannot penetrate these materials, leaving them non-sterile.

Sensitive Biological and Chemical Compounds

Many complex molecules are destroyed by extreme heat.

High-protein solutions, serums, vaccines, and certain Active Pharmaceutical Ingredients (APIs) will degrade or denature, rendering them useless. These materials often require sterile filtration without heat.

Understanding the Operational Constraints

Beyond material incompatibility, the process itself introduces limitations that require careful management to ensure effective and safe sterilization.

The Requirement for Steam Penetration

Sterilization will fail if steam cannot reach every surface. This operational constraint is a frequent source of error.

Overcrowding the chamber prevents steam from circulating freely. Similarly, wrapping items in materials like aluminum foil blocks steam contact and must be avoided. Items must be loaded to allow for complete steam penetration.

The Problem of Moisture Retention

A primary drawback of the process is moisture retention. Items emerge from the autoclave wet and often require a separate drying cycle or air-drying period.

This not only adds time to the overall process but can also introduce a risk of re-contamination if items are handled or stored improperly while still damp.

Inherent Safety Risks

Operating a device that generates high pressure and temperature demands strict adherence to safety protocols.

Attempting to autoclave liquids in a sealed container can lead to an explosion. Users must ensure the chamber is properly sealed before operation and never opened while it is still hot and pressurized.

Common Pitfalls to Avoid

Mistakes in preparation or material selection are the most common reasons for autoclave failure. These errors not only risk incomplete sterilization but can also damage the equipment and pose a safety hazard.

Mixing Incompatible Loads

Never autoclave waste and clean items in the same cycle. Different materials and levels of contamination require different parameters for effective sterilization.

Using Improper Containers

Placing items in trays or containers that are not autoclave-safe is a critical error. As mentioned, polyethylene trays can melt and fuse to the inside of the chamber, resulting in costly repairs.

Ignoring Manufacturer Guidelines

Every autoclave model has specific instructions for water levels, loading configurations, and cycle settings. Deviating from the user manual can lead to failed cycles or equipment damage.

Making the Right Choice for Your Goal

Selecting the correct sterilization method is critical for ensuring the safety of your process and the integrity of your materials. The limitations of an autoclave define when it is the right tool and when you must seek an alternative.

- If your primary focus is sterilizing lab media, glassware, and stainless steel tools: The autoclave remains the most economical and efficient choice for these heat- and moisture-stable items.

- If your primary focus is sterilizing sharp carbon-steel instruments or heat-sensitive plastics: You must use a low-temperature method, such as chemical or gas sterilization, to prevent damage.

- If your primary focus is sterilizing oils, powders, or other waterproof substances: A dry-heat oven is the appropriate tool, as steam-based autoclaving will be completely ineffective.

Understanding these fundamental boundaries empowers you to use this powerful tool safely and effectively.

Summary Table:

| Limitation Category | Key Examples | Key Impact |

|---|---|---|

| Material Incompatibility | Heat-sensitive plastics, carbon steel instruments, oils/powders | Damage to items, ineffective sterilization |

| Operational Constraints | Overcrowding, improper wrapping, moisture retention | Failed sterilization cycles, safety hazards |

| Process Requirements | Specific loading, cycle settings, drying time | Increased process time, potential for user error |

Need help selecting the right sterilization equipment for your lab's specific materials?

At KINTEK, we understand that choosing between an autoclave, dry-heat oven, or other sterilization method is critical to your workflow's success and the integrity of your samples. Our experts can help you navigate the limitations of different equipment to find the perfect solution for sterilizing your heat-sensitive plastics, sharp instruments, or moisture-stable glassware.

Contact our lab equipment specialists today to ensure your sterilization processes are safe, effective, and tailored to your unique needs!

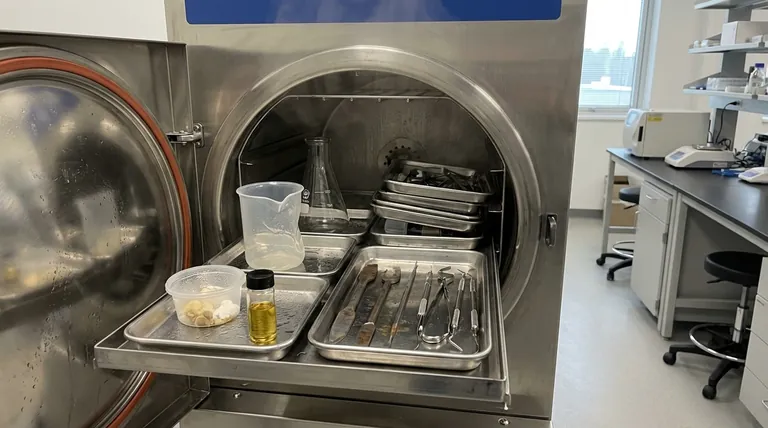

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- How does an autoclave ensure the reliability of experimental results? Achieving a Sterile Baseline for Lab Research

- What is the primary purpose of an autoclave in the preparation of media for the biological leaching of uranium?

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the necessity of using a steam autoclave for dental alloys? Ensure Pure Bacterial Adhesion Data

- Why is a 24-hour hydrothermal treatment in an autoclave necessary for BMO nanosheets? Unlock Superior Photocatalysis