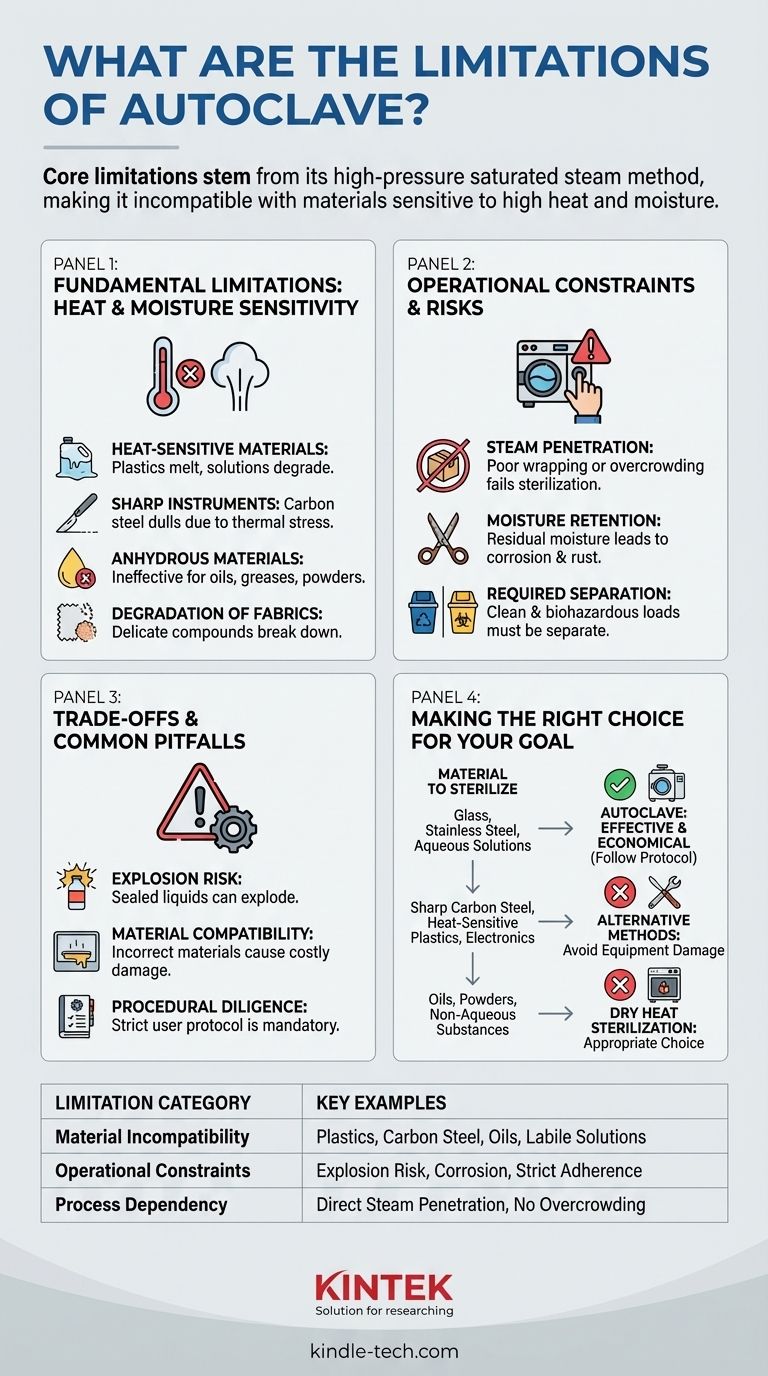

At its core, an autoclave's primary limitations stem from its very method of sterilization: high-pressure saturated steam. This process is incompatible with any material that is sensitive to high temperatures or moisture. Consequently, it cannot be used for certain plastics, sharp carbon steel instruments, oily substances, or heat-labile solutions.

The very power of an autoclave—its use of intense heat and penetrating steam—is also its greatest weakness. It is a highly effective method, but only for materials that can withstand its harsh conditions.

The Fundamental Limitation: Heat and Moisture Sensitivity

The effectiveness of an autoclave relies on steam reaching a temperature of at least 121°C (250°F). Any material that cannot tolerate this environment will be damaged or degraded, rendering the process unsuitable.

Damage to Heat-Sensitive Materials

Many common laboratory and medical materials cannot be autoclaved. Certain plastics will melt or warp, while complex solutions like vaccines, serums, and some high-protein compounds will degrade and lose their efficacy.

Dulling of Sharp Instruments

While stainless steel is generally safe, high-grade carbon steel instruments like scalpels and scissors will become dull under the high heat. The integrity of their fine cutting edges is compromised by the thermal stress.

Unsuitability for Anhydrous Materials

Steam sterilization is ineffective for substances that do not mix with water. This includes oils, greases, and powders. The steam cannot penetrate these materials, leaving them non-sterile.

Degradation of Fabrics and Compounds

Many chemical compounds break down when exposed to high heat, altering their properties. Similarly, delicate fabrics and linens can be damaged or destroyed by the intense temperature and moisture.

Operational Constraints and Procedural Risks

Beyond material incompatibility, effective autoclaving is dependent on strict adherence to procedure. Operator error or improper loading can easily lead to sterilization failure.

The Critical Role of Steam Penetration

For sterilization to occur, steam must come in direct contact with every surface. Overcrowding the chamber, improperly wrapping items, or using waterproof barriers like aluminum foil will create air pockets and prevent steam penetration, leaving items non-sterile.

Moisture Retention and Corrosion

The steam-based process inherently leaves residual moisture. This can be problematic for items that need to remain dry and can lead to corrosion and rust on susceptible metals like carbon steel.

Required Separation of Loads

To prevent cross-contamination, a critical procedural limitation is the need to autoclave clean items and biohazardous waste in separate cycles. This adds a layer of operational complexity and time.

Understanding the Trade-offs and Common Pitfalls

Using an autoclave is not a simple "set and forget" process. Understanding its risks is essential for both safety and successful sterilization.

The Risk of Explosion

Never autoclave liquids in a tightly sealed container. The build-up of steam pressure inside the container can cause it to explode, posing a significant safety hazard and potentially damaging the autoclave.

Material Compatibility is Non-Negotiable

Using incorrect materials can have severe consequences. For example, placing items on a polyethylene tray is a common mistake; the plastic can melt and cause significant, costly damage to the autoclave chamber.

Procedural Diligence is Mandatory

Safe and effective operation depends entirely on the user. Following the manual, adding the correct amount of water, ensuring the safety clamp is sealed, and allowing for proper steam circulation are not optional suggestions—they are absolute requirements.

Making the Right Choice for Your Goal

Ultimately, the decision to use an autoclave depends entirely on the material you need to sterilize.

- If your primary focus is sterilizing glassware, surgical-grade stainless steel, or stable aqueous solutions: The autoclave is an exceptionally effective and economical choice, provided you follow proper loading and safety protocols.

- If your primary focus is sterilizing sharp carbon steel instruments, heat-sensitive plastics, or electronics: You must use alternative low-temperature sterilization methods to avoid damaging your equipment.

- If your primary focus is sterilizing oils, powders, or other non-aqueous substances: Steam autoclaving is ineffective, and a method like dry heat sterilization is the appropriate choice.

Choosing the correct sterilization method is the first and most critical step in ensuring safety and efficacy.

Summary Table:

| Limitation Category | Key Examples |

|---|---|

| Material Incompatibility | Heat-sensitive plastics, carbon steel instruments, oils, powders, heat-labile solutions. |

| Operational Constraints | Risk of explosion, moisture retention/corrosion, need for separate loads, strict procedural adherence. |

| Process Dependency | Requires direct steam penetration; overcrowding or improper wrapping leads to failure. |

Ensure Effective and Safe Sterilization in Your Lab

Choosing the right sterilization method is critical for protecting your valuable equipment and ensuring process integrity. The limitations of autoclaves highlight the importance of matching your materials to the correct technology.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the complexities of sterilization to find the perfect solution for your specific application—whether it's an autoclave for compatible materials or an alternative method for heat-sensitive items.

Contact us today to discuss your lab's sterilization challenges and ensure your processes are both safe and effective.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the necessity of using a steam autoclave for dental alloys? Ensure Pure Bacterial Adhesion Data

- How does an autoclave ensure the reliability of experimental results? Achieving a Sterile Baseline for Lab Research

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- Why is a 24-hour hydrothermal treatment in an autoclave necessary for BMO nanosheets? Unlock Superior Photocatalysis

- How should solid materials in bags be prepared for decontamination? Master Steam Penetration for Safe Sterilization