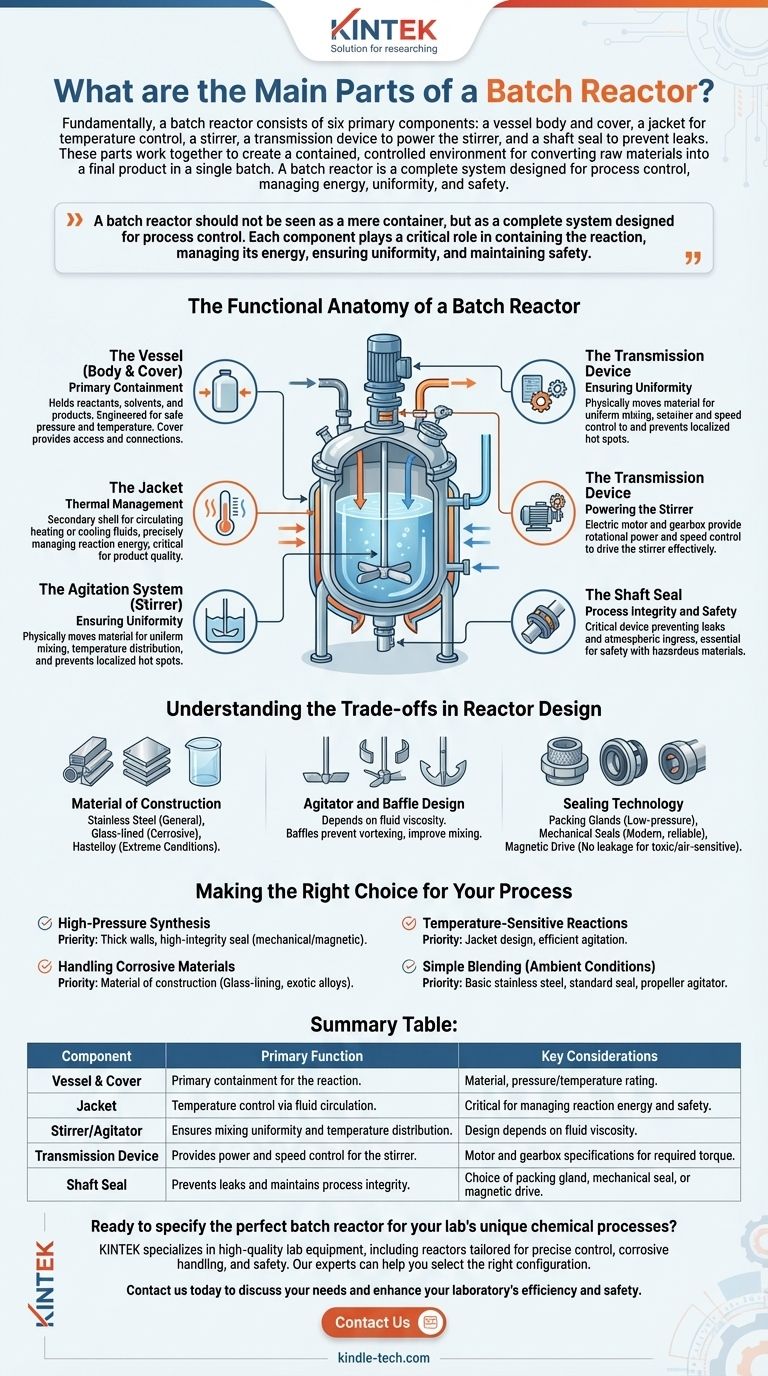

Fundamentally, a batch reactor consists of six primary components: a vessel body and cover, a jacket for temperature control, a stirrer, a transmission device to power the stirrer, and a shaft seal to prevent leaks. These parts work together to create a contained, controlled environment where raw materials can be converted into a final product in a single batch.

A batch reactor should not be seen as a mere container, but as a complete system designed for process control. Each component plays a critical role in containing the reaction, managing its energy, ensuring uniformity, and maintaining safety.

The Functional Anatomy of a Batch Reactor

A batch reactor's design is driven by the need to precisely manage a chemical process from start to finish. Each part serves a distinct and vital function.

The Vessel: Primary Containment

The kettle body and kettle cover form the main vessel. This is the primary containment structure that holds the reactants, solvents, and eventual products.

The vessel is engineered to safely withstand the expected pressure and temperature of the chemical reaction. The cover provides access for charging materials and includes nozzles for instrumentation, vents, and other connections.

The Jacket: Thermal Management

The jacket is a secondary shell that wraps around the main vessel body. This is the reactor's primary mechanism for temperature control.

A heating or cooling fluid (like steam, water, or thermal oil) is circulated through the space between the jacket and the vessel wall. This allows for precise management of the reaction's energy, which is critical for controlling reaction rates and ensuring product quality, especially in energy-sensitive processes like pyrolysis.

The Agitation System: Ensuring Uniformity

The agitation system consists of the stirrer (or agitator) and the transmission device. Its purpose is to ensure the batch is thoroughly mixed.

The stirrer, which can have various designs like paddles, turbines, or anchors, physically moves the material inside the vessel. This promotes uniform temperature distribution and ensures reactants are in constant contact, preventing localized hot spots or concentration gradients.

The transmission device—typically an electric motor and gearbox—provides the rotational power and speed control needed to drive the stirrer effectively.

The Shaft Seal: Process Integrity and Safety

The shaft sealing device is a critical component located where the stirrer shaft enters the reactor vessel. Its sole purpose is to prevent the contents of the reactor from leaking out and to stop air from getting in.

This is non-negotiable for safety when dealing with flammable, toxic, or high-pressure materials. A robust seal ensures both environmental protection and the integrity of the chemical process itself.

Understanding the Trade-offs in Reactor Design

The selection of these components is not one-size-fits-all. The specific design is a series of engineering trade-offs based on the chemistry, operating conditions, and safety requirements of the process.

Material of Construction

The choice of material for the vessel and internal parts is paramount. Stainless steel is common for general use, but glass-lined steel is required for highly corrosive processes. For extreme temperature and pressure, specialized alloys like Hastelloy may be necessary.

Agitator and Baffle Design

The type of stirrer dramatically affects mixing efficiency. A high-viscosity fluid requires a different agitator (like an anchor) than a low-viscosity, water-like fluid (which might use a turbine). Internal baffles are also often added to the vessel wall to prevent vortexing and improve top-to-bottom mixing.

Sealing Technology

Simple packing glands may be sufficient for low-pressure, non-hazardous applications. However, most modern reactors use mechanical seals for better reliability. For processes where absolutely no leakage can be tolerated (e.g., highly toxic or air-sensitive chemistry), a magnetic drive is used to eliminate the shaft penetration entirely.

Making the Right Choice for Your Process

The ideal reactor configuration depends entirely on the primary goal of your chemical process.

- If your primary focus is high-pressure synthesis: Prioritize a vessel with thick walls and a high-integrity mechanical or magnetic seal.

- If your primary focus is temperature-sensitive reactions: The jacket design and the efficiency of the agitation system are the most critical factors for ensuring precise thermal control.

- If your primary focus is handling corrosive materials: The material of construction, specifically options like glass-lining or exotic alloys, is your most important decision.

- If your primary focus is simple blending at ambient conditions: A basic stainless steel vessel with a standard seal and a simple propeller agitator will likely suffice.

By understanding how these core components function and interact, you can specify a reactor that is not just a container, but an optimized tool for your specific chemical transformation.

Summary Table:

| Component | Primary Function | Key Considerations |

|---|---|---|

| Vessel & Cover | Primary containment for the reaction. | Material (e.g., stainless steel, glass-lined); pressure/temperature rating. |

| Jacket | Temperature control via heating/cooling fluid. | Critical for managing reaction energy and safety. |

| Stirrer/Agitator | Ensures mixing uniformity and temperature distribution. | Design (paddle, turbine, anchor) depends on fluid viscosity. |

| Transmission Device | Provides power and speed control for the stirrer. | Motor and gearbox specifications for required torque. |

| Shaft Seal | Prevents leaks and maintains process integrity. | Choice of packing gland, mechanical seal, or magnetic drive. |

Ready to specify the perfect batch reactor for your lab's unique chemical processes?

At KINTEK, we specialize in high-quality lab equipment, including reactors tailored for precise temperature control, handling corrosive materials, and ensuring operational safety. Our experts can help you select the right configuration—from vessel material to sealing technology—to optimize your synthesis, blending, or pyrolysis reactions.

Contact us today using the form below to discuss your specific needs and discover how KINTEK's solutions can enhance your laboratory's efficiency and safety.

Visual Guide

Related Products

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What environment does a PTFE-lined autoclave provide for TiO2-GQD synthesis? Achieve Superior Nanocomposite Results

- Why are stainless steel autoclaves key to PCL-TPE preparation? Mastering High-Vacuum Polycondensation

- How does a high-pressure hydrothermal autoclave facilitate the synthesis of BiVO4@PANI nanocomposites? Unlock Precision.

- What is the significance of the hydrothermal environment in HA preparation? Optimize Mesoporous Structure and Purity

- Which critical experimental conditions does a high-pressure autoclave provide? Optimize Mixed Sulfide Leaching