The standard minimum temperature for effective autoclave steam sterilization is 121°C (250°F). This temperature must be achieved using saturated steam at a corresponding pressure of approximately 15 psi (pounds per square inch) above atmospheric pressure. However, temperature and pressure are only two parts of the equation; this state must be maintained for a minimum duration to ensure all microorganisms are destroyed.

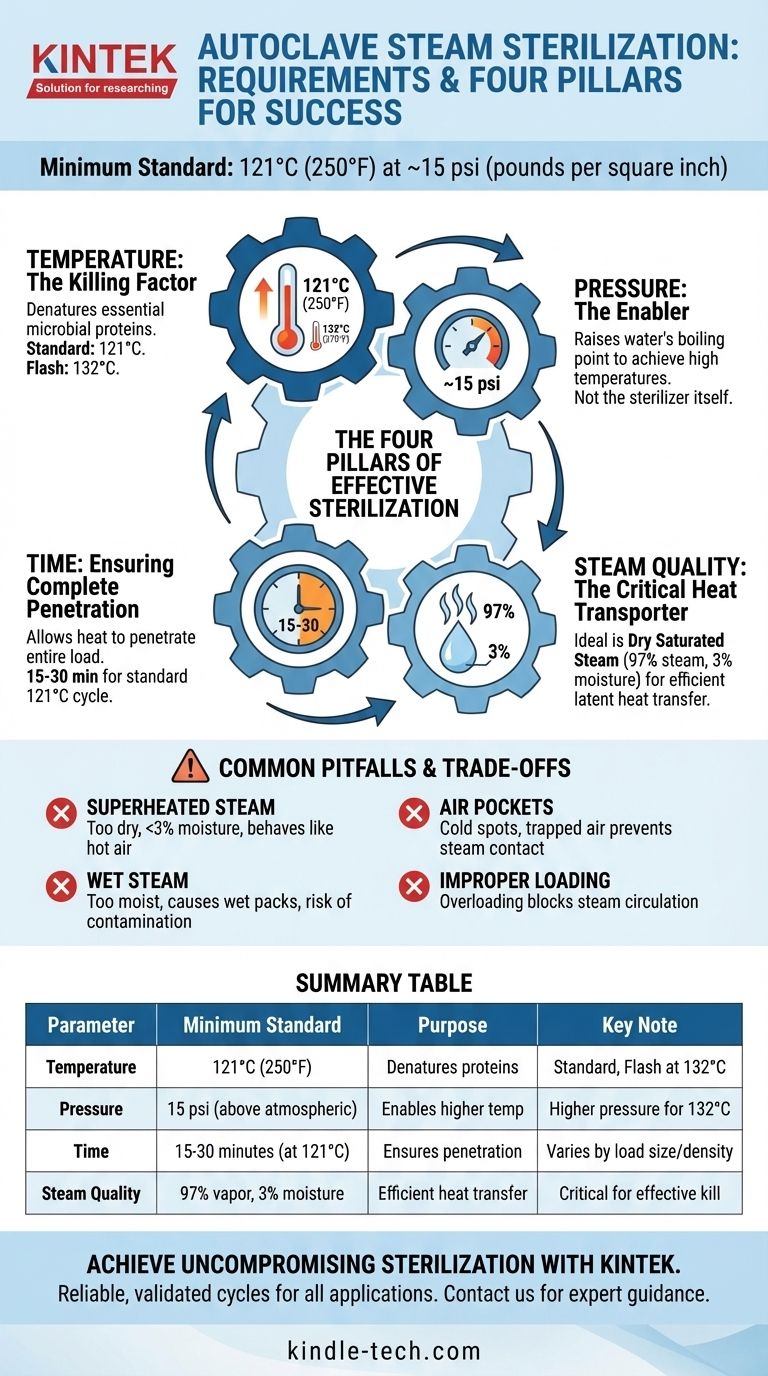

Successful sterilization is not achieved by simply setting a temperature and pressure. It is a function of four interdependent variables: temperature, pressure, time, and steam quality. Misunderstanding any one of these can lead to sterilization failure, even if the autoclave appears to have run correctly.

The Four Pillars of Effective Steam Sterilization

To ensure complete microbial inactivation, you must understand how each parameter contributes to the process. They do not work in isolation.

Temperature: The Killing Factor

High temperature is what denatures the essential proteins and enzymes that microorganisms need to survive.

The most common sterilization temperature is 121°C (250°F). A second common standard is 132°C (270°F), which is used for shorter cycles, often called "flash sterilization."

Pressure: The Enabler of High Temperature

Pressure itself does not sterilize. Its sole purpose is to increase the boiling point of water.

At normal atmospheric pressure, water boils at 100°C (212°F). By increasing the pressure inside the sealed autoclave chamber, we can create steam that is significantly hotter, making temperatures like 121°C possible.

Time: Ensuring Complete Penetration

The designated temperature must be held for a minimum contact time to be effective. This duration allows the heat to penetrate the entire load, including the interior of dense packs or the contents of liquids.

For a standard 121°C cycle, a minimum sterilization time of 15 to 30 minutes is common, depending on the size and nature of the load. Denser loads require longer times.

Steam Quality: The Critical Heat Transporter

This is the most overlooked yet most critical parameter. The ideal sterilizing agent is dry saturated steam with a specific composition: approximately 97% steam (vapor) and 3% moisture (entrained water).

This small amount of moisture is essential because it carries and transfers the steam's latent heat to the items with extreme efficiency. When the steam condenses on a cooler surface, it releases a massive amount of energy, causing rapid heating and microbial death.

Understanding the Trade-offs and Common Pitfalls

Relying on temperature and pressure readings alone is a common source of error. The quality of the steam and the nature of the load are just as important.

Superheated Steam: Too Dry to Be Effective

If the steam has less than 3% moisture, it becomes superheated (dry). This steam behaves more like hot air and is a very poor sterilizing agent. It transfers heat inefficiently and may fail to kill resistant microorganisms.

Wet Steam: The Problem of Incomplete Drying

If steam contains too much moisture, it can lead to wet packs. Items that remain wet after a cycle are easily contaminated as they are removed from the autoclave. The moisture can wick microorganisms through the packaging, compromising sterility.

Air Pockets: The Cold Spots of Sterilization

Trapped air is the enemy of steam sterilization. If air is not properly removed from the chamber and the load, it creates "cold spots" where steam cannot make contact. Microorganisms in these air pockets will survive the cycle. This is why many autoclaves use pre-vacuum cycles to remove air before introducing steam.

Improper Loading: The Enemy of Penetration

Overloading the autoclave or packing items too tightly prevents steam from circulating freely. This is a common operational error that blocks steam penetration, leaving parts of the load unsterilized regardless of the cycle settings.

Making the Right Choice for Your Application

To ensure sterility, you must match the cycle parameters to the specific items being processed.

- If your primary focus is standard laboratory media or non-porous instruments: A gravity displacement cycle at 121°C and 15 psi for 30 minutes is the universally accepted standard.

- If your primary focus is rapid turnaround of unwrapped, durable instruments: A "flash" cycle using a pre-vacuum system at 132°C and ~30 psi for 4-5 minutes may be appropriate, but requires strict validation.

- If your primary focus is porous loads like surgical gowns or animal bedding: A pre-vacuum cycle is non-negotiable to ensure complete air removal and steam penetration.

- If you are validating any new process or load configuration: Always use chemical and biological indicators placed in the most challenging parts of the load to prove that sterilizing conditions were achieved.

Focusing on the interplay of time, temperature, pressure, and steam quality transforms sterilization from a simple machine setting into a reliable scientific process.

Summary Table:

| Parameter | Minimum Standard | Purpose |

|---|---|---|

| Temperature | 121°C (250°F) | Denatures microbial proteins for sterilization. |

| Pressure | 15 psi above atmospheric | Enables higher steam temperatures by raising water's boiling point. |

| Time | 15-30 minutes at 121°C | Ensures heat penetrates the entire load for complete microbial kill. |

| Steam Quality | Dry saturated steam (97% vapor, 3% moisture) | Efficiently transfers latent heat to items for effective sterilization. |

Achieve Uncompromising Sterilization with KINTEK

Understanding the precise balance of temperature, pressure, time, and steam quality is fundamental to your lab's safety and compliance. KINTEK specializes in high-performance autoclaves and lab equipment designed to deliver reliable, validated sterilization cycles for a wide range of applications—from standard media preparation to complex porous loads.

Our experts can help you select the right autoclave and validate your processes to ensure complete sterility every time. Don't leave your results to chance.

Contact KINTEK today to discuss your laboratory's sterilization needs and ensure your processes are built on a foundation of reliability and precision.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam