To achieve effective autoclave sterilization, materials must be exposed to high-pressure saturated steam at a specific temperature for a designated duration. The standard requirements are a temperature between 121°C (250°F) and 134°C (273°F) for a minimum of 15 to 20 minutes. Crucially, this process depends on direct steam contact with every surface to be sterilized.

The core principle of autoclave sterilization is not just heat, but the use of pressurized, saturated steam. Pressure is the tool used to raise the temperature of steam far above water's normal boiling point, allowing the moist heat to rapidly penetrate and destroy all microorganisms.

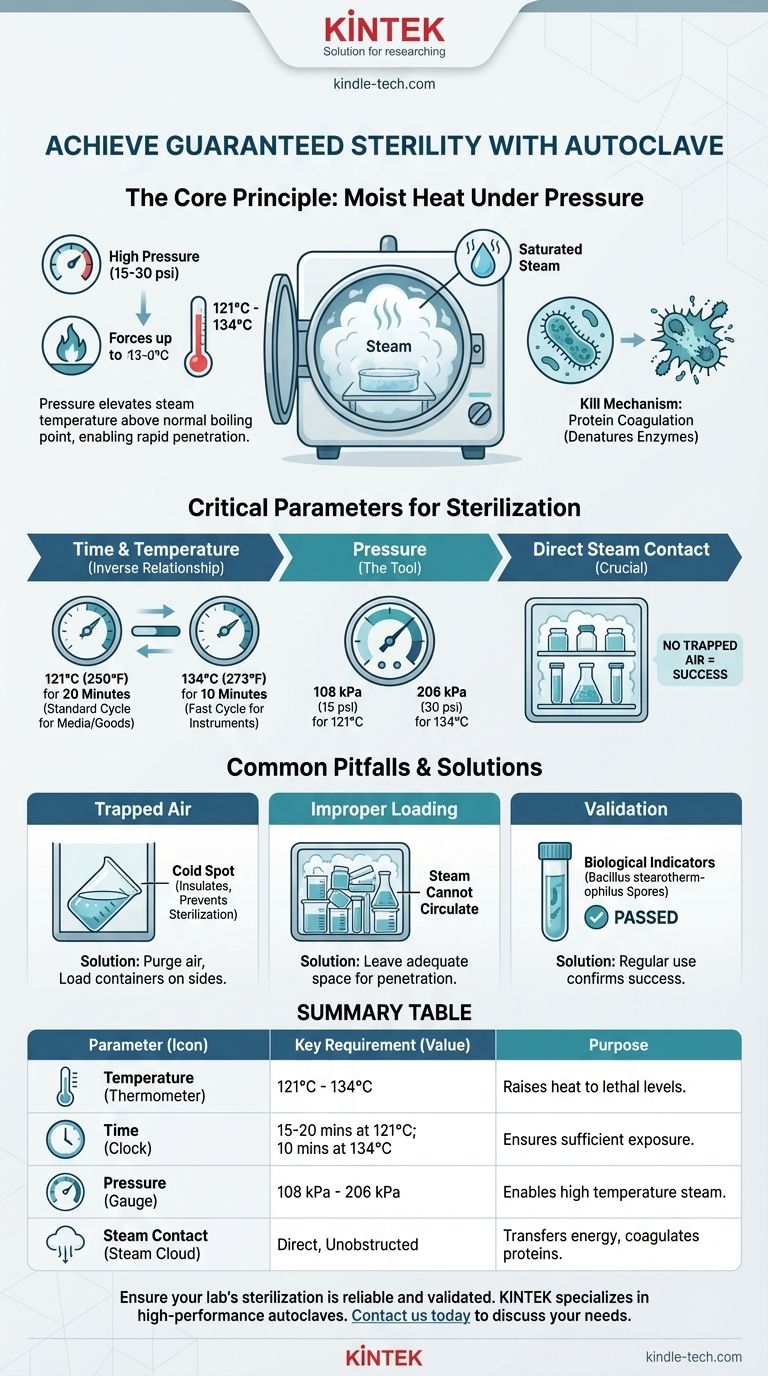

The Core Principle: Moist Heat Under Pressure

To properly use an autoclave, it's essential to understand why it works. The process relies on a direct relationship between pressure, temperature, and the lethal power of moist heat.

How Pressure Elevates Temperature

At normal atmospheric pressure, water boils at 100°C (212°F). By sealing the autoclave chamber and forcing in steam, the internal pressure increases dramatically.

According to the laws of physics, this increase in pressure raises the boiling point of water. This allows the steam inside to reach temperatures high enough to kill even the most heat-resistant microorganisms, like bacterial endospores.

The Power of Saturated Steam

An autoclave uses moist heat, not dry heat. Saturated steam is an incredibly efficient medium for transferring thermal energy.

When this high-temperature steam makes contact with cooler items in the chamber, it condenses into water, releasing its stored energy directly onto the surface. This rapid heat transfer is far more effective at killing microbes than dry air at the same temperature.

The Kill Mechanism: Protein Coagulation

The combination of intense heat and moisture is lethal to cellular life. It works by coagulating and irreversibly denaturing the essential proteins and enzymes within microorganisms.

This process is similar to how an egg white solidifies when cooked. Once these proteins are denatured, the microbe's cellular functions cease, leading to its death.

The Critical Parameters for Sterilization

Effective sterilization is a function of three interdependent variables: time, temperature, and steam contact.

Temperature and Time

Temperature and time have an inverse relationship. A higher temperature can effectively sterilize in a shorter period.

The most common standard cycle is 121°C (250°F) for at least 20 minutes.

A faster cycle, often used for unwrapped metal instruments, is 134°C (273°F) for 10 minutes.

Pressure

Pressure is the means to achieve the target temperature. It is not, by itself, the sterilizing agent.

For a temperature of 121°C, the corresponding pressure is typically around 108 kPa (15 psi) above atmospheric pressure. To reach 134°C, a higher pressure of about 206 kPa (30 psi) is required.

Direct Steam Contact

This is the most critical and often overlooked requirement. If steam cannot reach a surface, that surface will not be sterilized, regardless of the cycle time or temperature.

Any trapped air will create a "cold spot" that insulates materials from the steam, preventing sterilization.

Common Pitfalls and How to Avoid Them

Achieving the right numbers on the gauge does not guarantee sterilization. The process must be validated, and common errors must be avoided.

The Problem of Trapped Air

Air is a poor conductor of heat and a major barrier to steam penetration. Ensure all air is purged from the chamber during the initial phase of the autoclave cycle. Containers should be placed on their sides to prevent air from being trapped inside.

Improper Loading

Overloading the autoclave or packing items too densely will prevent steam from circulating freely. This is a common cause of sterilization failure. Always leave adequate space between all items to ensure steam can penetrate the entire load.

The Necessity of Validation

The only way to be certain a sterilization cycle was successful is through validation. This is done using biological indicators.

These indicators contain spores of a highly heat-resistant bacterium, typically Bacillus stearothermophilus. If the spores are killed during the cycle, it provides a high degree of assurance that all other microorganisms have also been destroyed.

Making the Right Choice for Your Goal

Select your autoclave cycle based on the materials being sterilized and your operational needs.

- If your primary focus is standard sterilization of lab media or durable goods: Use the 121°C for 20 minutes cycle, as this is the universally accepted standard that is effective and gentle on most materials.

- If your primary focus is the fastest possible turnaround for unwrapped instruments: The 134°C for 10 minutes cycle is highly effective, but ensure your items can withstand the higher temperature.

- If your primary focus is confirming absolute sterility for critical applications: Always supplement physical monitoring (temperature, pressure gauges) with regular use of biological indicators to validate the process.

Understanding these core requirements empowers you to move beyond simply running a machine and toward ensuring true, reliable sterilization every time.

Summary Table:

| Parameter | Key Requirement | Purpose |

|---|---|---|

| Temperature | 121°C (250°F) to 134°C (273°F) | Raises heat to lethal levels for microorganisms. |

| Time | 15-20 minutes at 121°C; 10 minutes at 134°C | Ensures sufficient exposure for complete kill. |

| Pressure | 108 kPa (15 psi) to 206 kPa (30 psi) | Enables steam to reach required high temperatures. |

| Steam Contact | Direct, unobstructed contact with all surfaces | Allows moist heat to transfer energy and coagulate proteins. |

Ensure your lab's sterilization is reliable and validated. KINTEK specializes in high-performance autoclaves and laboratory equipment designed to meet stringent sterilization requirements. Our experts can help you select the right autoclave for your specific applications, from standard media preparation to critical instrument processing. Contact us today to discuss your lab's needs and achieve guaranteed sterility.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the principle and structure of autoclave? Unlock the Power of High-Pressure Steam Sterilization

- Why is a PTFE-lined stainless steel autoclave required for Ag@N-TiO2? Ensure Purity and Performance in Synthesis

- What is the use of autoclave in microbiology? Ensuring Sterile Conditions for Reliable Results

- Can you sterilize instruments without an autoclave? Discover Effective Alternatives for Your Lab

- How are autoclaves used to sterilize surgical instruments? Master the Key Steps for Patient Safety

- What are the uses of autoclave in laboratory equipment? Ensure Sterile Conditions for Your Research

- What is the temperature range of an autoclave? From 121°C to 134°C for Optimal Sterilization

- How can autoclave be used to control microorganisms? Achieve Absolute Sterilization with Steam & Pressure