The primary safety concerns with autoclaving center on three critical risks: severe burns from superheated steam and materials, explosive decompression from improperly contained items, and exposure to biohazards due to incomplete sterilization. These dangers arise from the extreme heat and pressure required for steam sterilization.

Safe autoclave operation is not about memorizing a list of rules, but about mastering a disciplined process. The core principle is ensuring that high-pressure steam can freely penetrate, sterilize, and then safely dissipate from every item in the chamber.

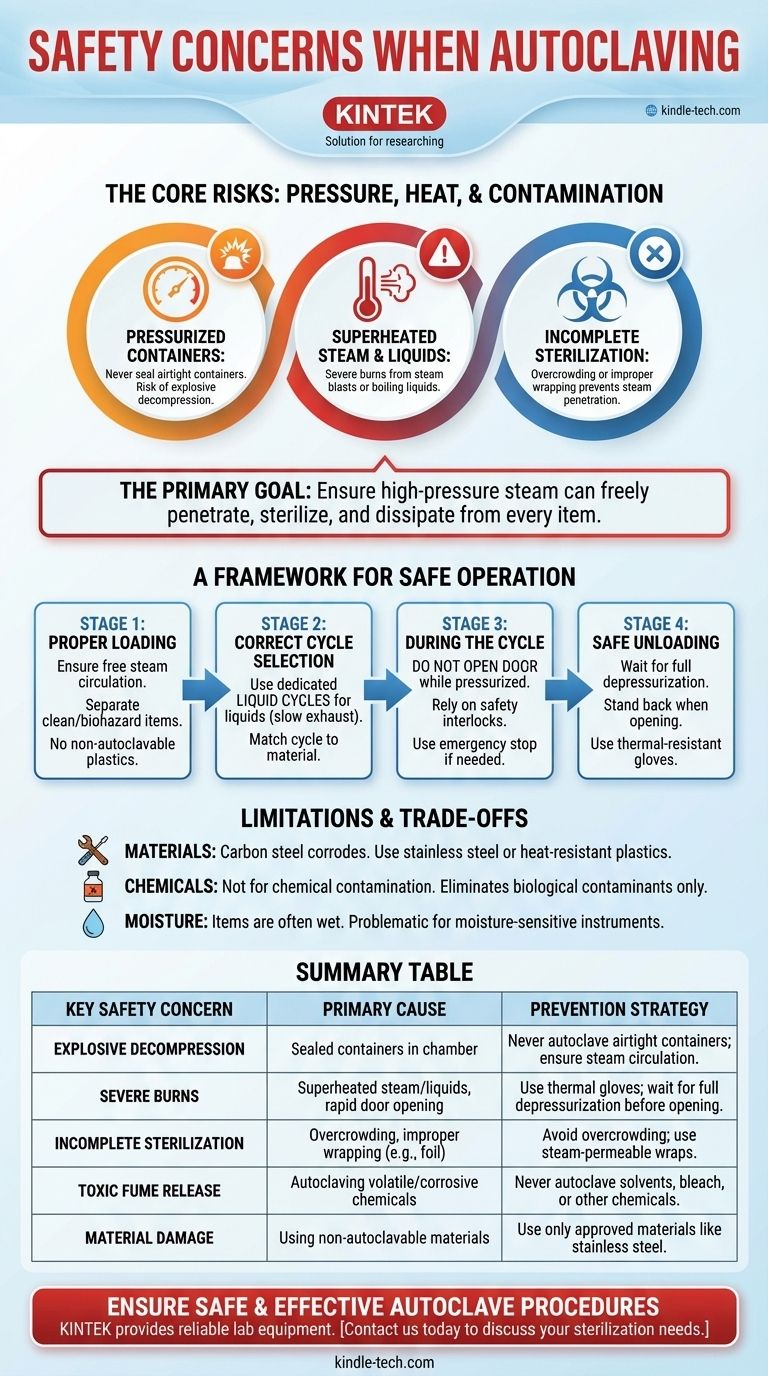

The Core Risks: Pressure, Heat, and Contamination

An autoclave harnesses immense physical forces to achieve sterilization. Understanding these forces is the first step to mitigating the risks they present.

The Danger of Pressurized Containers

Never place a sealed, airtight container in an autoclave.

As the temperature inside the chamber rises, the liquid and air inside a sealed container expand, creating immense internal pressure. This can easily cause glass or plastic containers to explode violently, damaging the equipment and creating a severe hazard.

The Hazard of Superheated Steam and Liquids

The contents of the autoclave remain extremely hot and under pressure even after a cycle completes.

Opening the door too quickly can release a blast of superheated steam, causing severe burns. Liquids, especially water, can remain at temperatures above boiling point and can flash-boil or erupt if agitated, creating a significant scalding risk.

The Risk of Incomplete Sterilization

Improper loading is a primary cause of failed sterilization cycles.

If the chamber is overcrowded or items are wrapped in materials like aluminum foil, steam cannot penetrate and make contact with all surfaces. This failure leaves you with non-sterile, potentially biohazardous material.

The Threat of Chemical Vapors

An autoclave is not designed to handle volatile or corrosive chemicals.

Never autoclave items containing solvents, bleach, or other chemicals. Heating these substances can release toxic or flammable fumes, creating a dangerous atmosphere in the lab and potentially damaging the autoclave itself.

A Framework for Safe Operation

A systematic approach to every autoclave run is the most effective way to ensure safety. This involves careful preparation, correct operation, and patient unloading.

Stage 1: Proper Loading and Preparation

What you put into the autoclave, and how you put it in, matters most.

Always ensure items are clean and arranged to allow for free steam circulation. Never use polyethylene trays or other plastics not rated for autoclave temperatures, as they can melt and cause significant damage.

Critically, separate clean items from biohazardous waste by running them in different cycles to prevent cross-contamination.

Stage 2: Selecting the Correct Cycle

The type of material dictates the type of cycle you must use.

Liquid cycles are designed with a slow exhaust phase to prevent liquids from boiling over. Using a faster gravity or vacuum cycle for liquids is a common and dangerous mistake. Always consult the machine's manual for guidance.

Stage 3: During the Cycle

Once the cycle has started, the machine's safety interlocks are your primary protection.

Do not attempt to open the door while the machine is pressurized. Forcing the door can damage the locking mechanism and cause a catastrophic failure. If you suspect a problem, use the abort or emergency stop function and wait for the system to fully cool and depressurize.

Stage 4: Safe Unloading Procedures

Patience during unloading is a non-negotiable safety rule.

Wait for the chamber pressure to return to a safe, ambient level before attempting to open the door. Stand back when you first open it to avoid any residual steam, and use thermal-resistant gloves to handle the still-hot contents.

Understanding the Limitations and Trade-offs

While highly effective, autoclaves have specific limitations that operators must respect to ensure both safety and the integrity of their equipment.

Materials Prone to Damage

Steam and high heat can damage certain materials.

Carbon steel instruments can be corroded by the moisture in an autoclave, making them unsuitable for this sterilization method. Only stainless steel tools and specific, heat-resistant plastics should be used.

Ineffectiveness Against Chemical Contamination

An autoclave sterilizes; it does not remove or neutralize chemicals.

If an item is chemically contaminated, autoclaving will not make it safe. This process is exclusively for eliminating biological contaminants like bacteria, viruses, and spores.

The Issue of Moisture Retention

Items removed from an autoclave are often wet.

This retained moisture can be a disadvantage for certain applications and is a primary reason why moisture-sensitive instruments should not be autoclaved.

Making the Right Choice for Your Goal

Your specific objective determines your exact safety protocol. Use these principles as your guide.

- If your primary focus is sterilizing liquids: Use a dedicated liquid cycle with a slow exhaust and never seal the container cap tightly.

- If your primary focus is sterilizing solid instruments (glassware, metal): A standard gravity cycle is effective, but ensure steam can reach every surface and do not overload the chamber.

- If your primary focus is decontaminating biohazardous waste: Use autoclave-safe bags, leave them partially open for steam entry, and place them in a secondary, leak-proof tray.

By following a disciplined procedure, you transform a potentially hazardous device into an essential and reliable tool for your work.

Summary Table:

| Key Safety Concern | Primary Cause | Prevention Strategy |

|---|---|---|

| Explosive Decompression | Sealed containers in chamber | Never autoclave airtight containers; ensure steam can circulate freely. |

| Severe Burns | Superheated steam/liquids, rapid door opening | Use thermal gloves; wait for full depressurization before opening door. |

| Incomplete Sterilization | Overcrowding, improper wrapping (e.g., foil) | Avoid overcrowding; use steam-permeable wraps; separate clean and biohazardous loads. |

| Toxic Fume Release | Autoclaving volatile/corrosive chemicals | Never autoclave solvents, bleach, or other chemicals. |

| Material Damage | Using non-autoclavable materials (e.g., certain plastics, carbon steel) | Use only approved materials like stainless steel and autoclave-rated plastics. |

Ensure your lab's autoclave procedures are safe and effective. KINTEK specializes in providing reliable lab equipment and consumables, including autoclaves and accessories, to help you maintain a secure and sterile environment. Our experts can help you select the right equipment and understand best practices for your specific applications. Contact us today to discuss your laboratory's sterilization needs and enhance your safety protocols.

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- How is high pressure generated in an autoclave? Unlock the Science of Sterilization & Synthesis

- What are the design requirements for a corrosion-resistant autoclave? Expert Solutions for Scheelite Leaching

- What materials can be sterilized in an autoclave? A Guide to Heat-Stable & Steam-Permeable Items

- What are the parameters of an autoclave machine? Master Temperature, Pressure & Time for Sterility

- For what purpose are high-pressure autoclaves used in the synthesis of additives for composite polymer electrolytes?

- Why is a high-pressure steam sterilizer or autoclave required during the biomass pretreatment process? Optimize Yields

- What is the difference between dry-heat and steam sterilization? A Guide to Choosing the Right Method

- What is the purpose of the autoclave? Achieve Absolute Sterilization with Pressurized Steam