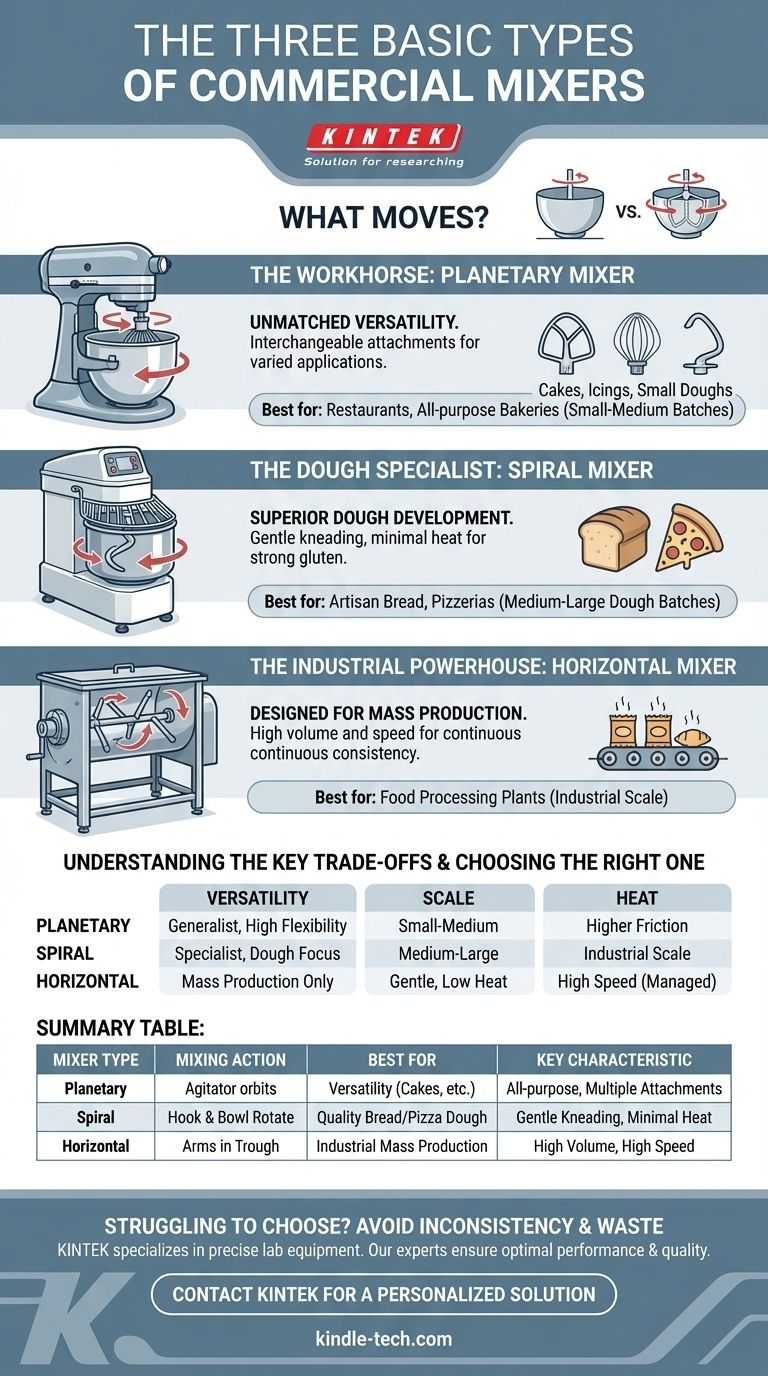

The three primary types of commercial mixers are the Planetary Mixer, the Spiral Mixer, and the Horizontal Mixer. Each is designed around a distinct mixing action, making them suited for vastly different applications, from versatile pastry work to high-volume industrial bread production.

The fundamental difference between mixers isn't just their size, but what moves. Understanding whether the tool, the bowl, or both are in motion is the key to selecting the right machine for your specific product and scale.

The Workhorse: The Planetary Mixer

The planetary mixer is named for its unique mixing action. The agitator (beater, whip, or hook) spins on its own axis while also orbiting around the inside of a stationary bowl, much like a planet orbiting the sun.

Unmatched Versatility

This design allows for incredibly thorough mixing of the entire bowl contents. It is the most versatile type of mixer due to its interchangeable attachments.

With a flat beater, wire whip, and dough hook, a single machine can cream butter and sugar, whip meringue, or knead small batches of dough.

Best for Varied Applications

Planetary mixers are the standard in restaurants, cake shops, and all-purpose bakeries. They excel where a variety of different products are made in small-to-medium batches.

The Dough Specialist: The Spiral Mixer

In a spiral mixer, both the mixing hook (shaped like a spiral or corkscrew) and the bowl rotate simultaneously. This synchronized action provides a gentle yet highly efficient kneading process.

Superior Dough Development

This dual-rotation method keeps friction and heat to a minimum. This is critical for developing a strong gluten structure in bread and pizza doughs without overworking or overheating them.

Best for Bakeries and Pizzerias

The spiral mixer is the preferred choice for any operation focused on dough, especially artisan breads. While it excels at its one job, it is not a versatile, all-purpose machine like a planetary mixer.

The Industrial Powerhouse: The Horizontal Mixer

The horizontal mixer is built for sheer volume and speed. It uses a horizontal shaft with various mixing arms or bars rotating inside a stationary, trough-like bowl.

Designed for Mass Production

These machines are engineered for continuous or very large batch production in industrial settings. They can incorporate ingredients and develop dough on a massive scale in a very short amount of time.

Best for Food Processing Plants

You will find horizontal mixers in large commercial bakeries and food manufacturing facilities. They are the engine behind most mass-produced breads, cookies, and snacks, valued for their immense capacity and consistency.

Understanding the Key Trade-offs

Choosing a mixer involves balancing versatility, specialization, and scale. No single mixer is best for every task.

Versatility vs. Specialization

A planetary mixer is a generalist; it can do many things well but may not be the absolute best for high-volume bread. A spiral mixer is a specialist; it's exceptional for dough but cannot be used for batters or creams.

Batch Size and Scale

Your required output dictates the appropriate machine. Planetary mixers handle small-to-medium batches, spiral mixers are for medium-to-large dough batches, and horizontal mixers are exclusively for industrial-scale production.

Dough Quality and Heat

For sensitive doughs where temperature control is critical, the spiral mixer's gentle action is superior. The high-speed action of a planetary mixer can introduce more friction and heat, which must be carefully managed.

Making the Right Choice for Your Operation

The ideal mixer is the one whose core design principles align with your primary production goals.

- If your primary focus is versatility for various products like cakes, icings, and small doughs: The Planetary mixer offers the greatest flexibility and is the most common choice for general food service.

- If your primary focus is high-quality artisan bread or pizza dough at scale: The Spiral mixer provides superior dough development, temperature control, and consistency for this specific task.

- If your primary focus is mass-producing a consistent product at an industrial level: The Horizontal mixer is the only solution designed for that immense level of throughput.

Ultimately, matching the mixer's mechanical action to your specific product is the key to achieving operational efficiency and quality.

Summary Table:

| Mixer Type | Mixing Action | Best For | Key Characteristic |

|---|---|---|---|

| Planetary Mixer | Agitator orbits in a stationary bowl | Versatility (cakes, icings, small doughs) | All-purpose, multiple attachments |

| Spiral Mixer | Spiral hook & bowl rotate together | High-quality bread & pizza dough | Gentle kneading, minimal heat |

| Horizontal Mixer | Arms rotate in a stationary trough | Industrial-scale mass production | High volume, high speed |

Struggling to choose the right mixer for your lab, bakery, or food production line? The wrong equipment can lead to inconsistent results, product waste, and operational inefficiency. At KINTEK, we specialize in providing the precise lab equipment and consumables you need to achieve perfect results every time. Our experts can help you select the ideal mixer for your specific application, ensuring optimal performance and quality. Contact us today via the form below to discuss your requirements and let us help you enhance your production process.

Contact KINTEK for a Personalized Solution

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Small Lab Rubber Calendering Machine

People Also Ask

- What is grinder in chemistry? A Guide to Precision Sample Preparation

- What is the difference between mixer and disperser? Choose the Right Tool for Your Process

- Why is a rotary mechanical homogenizer used for extended periods for forsterite-spinel? Achieve Peak Ceramic Uniformity

- What is the function of high-shear dispersion equipment in corona-resistant nanocomposites? Elevate Your Insulation

- How does a constant temperature rotary shaker contribute to evaluating iron nanoparticles? Optimize Dye Degradation