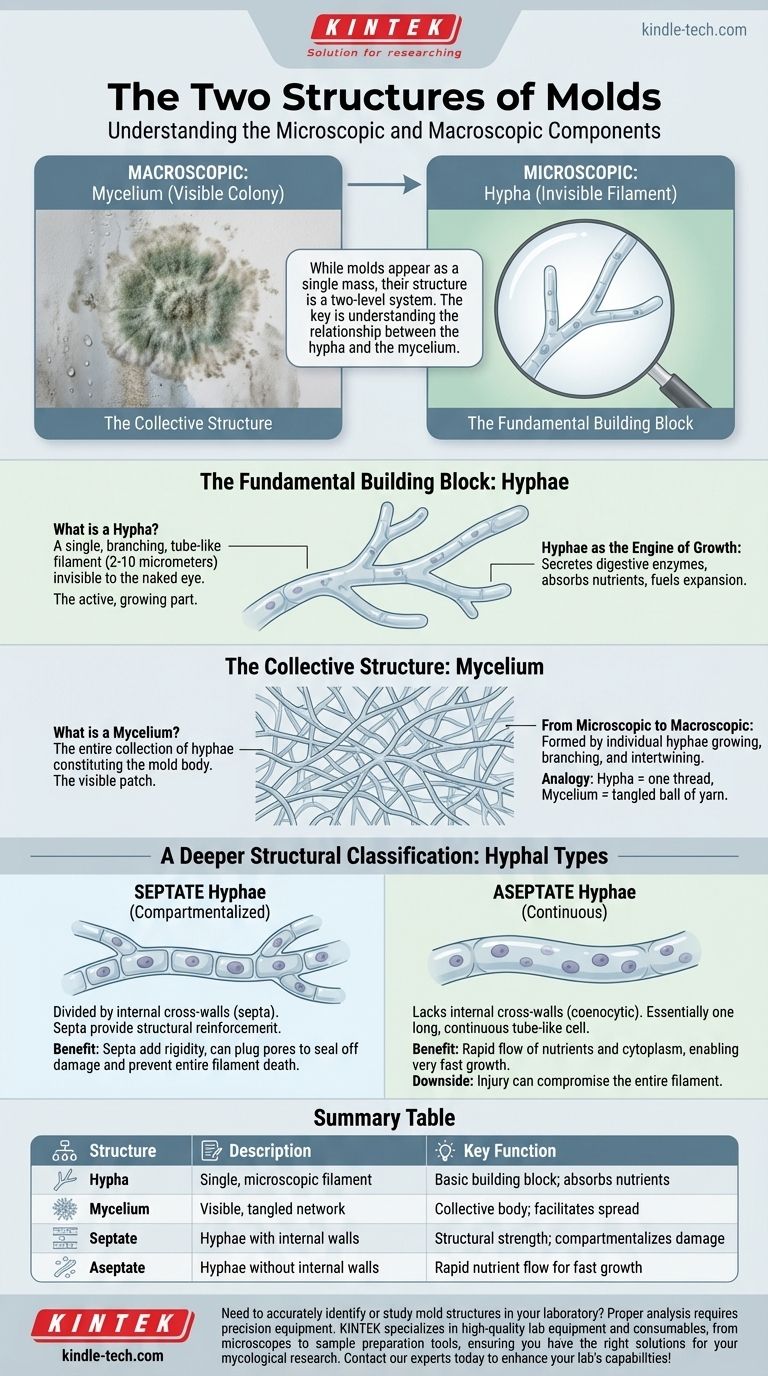

At the most fundamental level, a mold has two distinct structural components. The first is the hypha, which is the single microscopic filament, and the second is the mycelium, which is the visible, tangled mass formed by a network of many hyphae.

While molds appear as a single mass, their structure is a two-level system. Understanding the relationship between the microscopic building block (hypha) and the macroscopic colony (mycelium) is the key to understanding how molds grow, feed, and spread.

The Fundamental Building Block: Hyphae

What is a Hypha?

A hypha (plural: hyphae) is the basic structural unit of a mold. It is a single, branching, tube-like filament, typically only 2-10 micrometers in diameter, making it invisible to the naked eye.

These filaments are the active, growing parts of the mold, elongating at their tips to explore new territory and absorb nutrients from the environment.

Hyphae as the Engine of Growth

The primary function of hyphae is to secrete digestive enzymes into the substrate they are growing on and absorb the resulting nutrients. This process fuels the growth and expansion of the entire organism.

The Collective Structure: Mycelium

What is a Mycelium?

A mycelium is the term for the entire collection of hyphae that constitutes the body of a mold. When you see a patch of mold on bread or a damp wall, you are looking at the mycelium.

From Microscopic to Macroscopic

The mycelium is formed as countless individual hyphae grow, branch, and intertwine. This creates a dense network or mat that can cover large areas.

Think of it like a ball of yarn: a single hypha is one thread, while the mycelium is the entire tangled ball you can see and hold.

A Deeper Structural Classification

Beyond the hypha/mycelium distinction, the hyphae themselves have two primary structural forms. This division is critical for mycologists when identifying different types of molds.

Septate Hyphae: The Compartmentalized Structure

Many molds have hyphae that are divided by internal cross-walls called septa. These septa partition the long filaments into individual, cell-like compartments.

Each compartment still contains one or more nuclei, but the septa provide structural reinforcement.

Aseptate Hyphae: The Continuous Structure

Other molds have aseptate (or coenocytic) hyphae, which lack these internal cross-walls. This structure is essentially one long, continuous, tube-like cell containing many nuclei.

Understanding the Trade-offs

The difference between septate and aseptate structures is not arbitrary; it reflects different evolutionary strategies with distinct advantages.

The Benefit of Compartments (Septate)

Septa add rigidity and strength to the hyphae. Crucially, if a portion of a septate hypha is damaged, the septa can often plug the pores in their walls, sealing off the injury and preventing the entire filament from dying.

The Benefit of Open Flow (Aseptate)

In an aseptate hypha, nutrients, water, and cytoplasm can flow rapidly and freely throughout the organism. This unimpeded transport can enable incredibly fast growth when conditions are favorable. The downside is that an injury at any point can compromise the entire filament.

Applying This Knowledge

Understanding these structural layers is essential for moving from simple observation to accurate identification.

- If your primary focus is recognizing mold growth: Knowing that the visible patch (mycelium) is a vast network of microscopic filaments (hyphae) helps explain how it spreads so effectively.

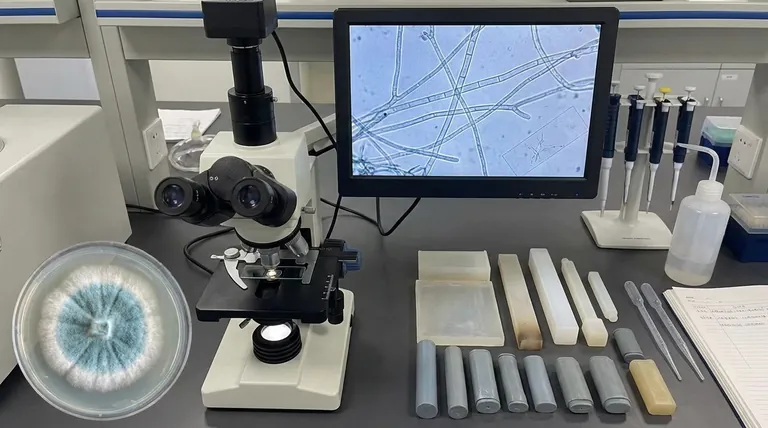

- If your primary focus is detailed scientific classification: Observing whether the hyphae are septate or aseptate under a microscope is a fundamental step in identifying the specific genus or species of mold.

Ultimately, grasping this dual structure of filament and network is the first principle in understanding the life of a fungus.

Summary Table:

| Structure | Description | Key Function |

|---|---|---|

| Hypha | A single, microscopic, tube-like filament. | The basic building block; absorbs nutrients and enables growth. |

| Mycelium | The visible, tangled mass formed by a network of hyphae. | The collective body of the mold; facilitates spread and colonization. |

| Hyphal Types | ||

| Septate Hyphae | Hyphae with internal cross-walls (septa). | Provides structural strength and can compartmentalize damage. |

| Aseptate Hyphae | Hyphae without internal walls (coenocytic). | Allows for rapid, unimpeded flow of nutrients for fast growth. |

Need to accurately identify or study mold structures in your laboratory? Proper analysis requires precision equipment. KINTEK specializes in high-quality lab equipment and consumables, from microscopes to sample preparation tools, ensuring you have the right solutions for your mycological research. Contact our experts today to enhance your lab's capabilities!

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What are the hazards of CNT? Understanding the Physical Risks of Carbon Nanotubes

- What are the differences between low-pressure and high-pressure heaters? Optimize Your Thermal Power Plant Efficiency

- What is the difference between burning and pyrolysis? Unlock Value from Waste Materials

- What is the long-term stability of viral analytes in plasma stored at -70°C? Proven for Decades of Research

- How does a controlled drying process ensure the quality of radiochromic films? Achieve Precise Dosimetric Results

- What are the three sample preparation techniques? Master the Key Stages for Accurate Analysis

- What is the temperature stability of graphite? Unlocking Extreme Heat Resistance in the Right Environment