In essence, a stainless steel reactor is a versatile, high-performance vessel designed for containing and controlling chemical reactions, mixing, or biological processes. They are the workhorse of numerous industries, including pharmaceutical, chemical, and food production, primarily chosen for their exceptional durability, corrosion resistance, and thermal performance.

The widespread use of stainless steel reactors stems from a simple truth: they offer a superior balance of chemical resistance, strength, and hygienic properties. Understanding the specific grade of steel and its limitations is the key to leveraging these vessels for safe and efficient production.

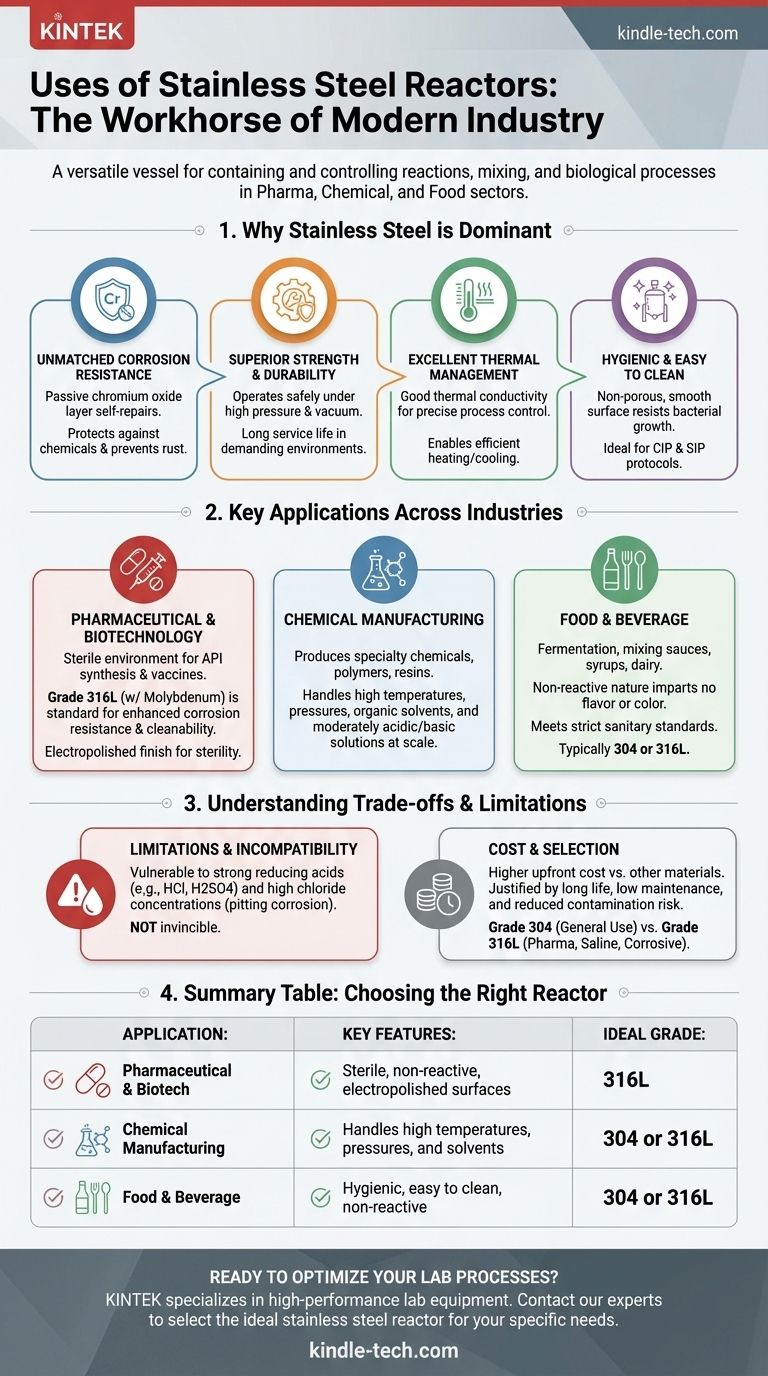

Why Stainless Steel is a Dominant Material

The choice of stainless steel is a calculated engineering decision based on a combination of material properties that are difficult to find in a single alternative.

Unmatched Corrosion Resistance

Stainless steel's primary advantage is its "passive" surface layer. A thin, invisible layer of chromium oxide naturally forms on the surface, which self-repairs when scratched.

This layer provides robust protection against a wide array of chemicals, water, and atmospheric conditions, preventing rust and product contamination.

Superior Strength and Durability

Steel's inherent mechanical strength allows these reactors to safely operate under significant internal pressure or high vacuum conditions without risk of catastrophic failure.

This structural integrity ensures a long service life even in demanding, continuous-operation industrial environments.

Excellent Thermal Management

Stainless steel possesses good thermal conductivity, a critical feature for process control. It allows for efficient and uniform heat transfer through the reactor jacket for heating or cooling.

This enables precise temperature management, which is essential for maximizing reaction yield, ensuring product quality, and maintaining process safety.

Hygienic and Easy to Clean

The surface of stainless steel is non-porous, smooth, and highly resistant to bacterial growth. This makes it exceptionally easy to clean and sanitize.

These reactors are ideal for Clean-in-Place (CIP) and Sterilize-in-Place (SIP) protocols, a non-negotiable requirement in the pharmaceutical and food industries where sterility is paramount.

Key Applications Across Industries

The unique properties of stainless steel make it suitable for a diverse range of critical applications.

Pharmaceutical & Biotechnology

In the synthesis of Active Pharmaceutical Ingredients (APIs), cell cultivation, and vaccine production, purity is everything. Stainless steel reactors ensure a sterile, non-reactive environment.

Grade 316L stainless steel, with its enhanced corrosion resistance due to molybdenum, is the standard. Surfaces are often electropolished to an even smoother finish to eliminate any potential sites for microbial contamination.

Chemical Manufacturing

These reactors are fundamental in producing specialty chemicals, polymers, resins, and paints. They can handle a broad spectrum of organic solvents, catalysts, and moderately acidic or basic solutions.

Their ability to withstand high temperatures and pressures makes them suitable for a wide variety of exothermic or endothermic reactions at scale.

Food & Beverage

From large-scale fermentation for beer and wine to the mixing of sauces, syrups, and dairy products, stainless steel is the material of choice.

Its non-reactive nature ensures that it does not impart any flavor or color to the final product, and its cleanability meets strict food-grade sanitary standards.

Understanding the Trade-offs and Limitations

While highly versatile, stainless steel is not universally compatible or always the most cost-effective choice. Acknowledging its limitations is crucial for proper selection.

Chemical Incompatibility

Stainless steel is not invincible. It is susceptible to corrosion from certain highly aggressive chemicals, particularly strong reducing acids like hydrochloric acid and sulfuric acid.

High concentrations of chlorides (found in salt water or as by-products of some reactions) can also cause "pitting corrosion," a localized form of corrosion that can lead to vessel failure. Always verify material compatibility.

The Upfront Cost Factor

Compared to materials like carbon steel or some specialized polymers, stainless steel reactors represent a higher initial capital investment.

However, this cost is often justified by a longer service life, lower maintenance requirements, and reduced risk of batch contamination, leading to a lower total cost of ownership.

Distinguishing Between Grades (304 vs. 316L)

Not all stainless steel is the same. Grade 304 is a common, general-purpose choice suitable for many applications, including much of the food industry.

Grade 316L contains molybdenum, which significantly enhances its resistance to chlorides and acids. It is the required standard for pharmaceutical applications and any process involving saline solutions or more corrosive chemicals. Using the wrong grade can lead to premature failure.

Selecting the Right Reactor for Your Process

Your specific process goal dictates the correct reactor choice. The decision should be based on a clear-eyed assessment of chemical compatibility, sanitary needs, and budget.

- If your primary focus is sterile production (Pharma/Biotech): Your only choice is a 316L stainless steel reactor, almost always with an electropolished finish to guarantee sterility and cleanability.

- If your primary focus is general chemical synthesis: A 304 or 316L reactor is a robust workhorse, but you must meticulously verify its compatibility with all process chemicals, paying special attention to chlorides and strong acids.

- If your primary focus is food and beverage processing: A food-grade stainless steel reactor (typically 304 or 316L) is necessary to meet hygienic standards and ensure product integrity.

- If your process involves high chloride concentrations or strong acids: You must look beyond standard stainless steel to more exotic alloys like Hastelloy or glass-lined steel reactors.

Choosing the right reactor is a foundational decision that directly impacts your process's safety, efficiency, and final product quality.

Summary Table:

| Application | Key Features | Ideal Stainless Steel Grade |

|---|---|---|

| Pharmaceutical & Biotechnology | Sterile, non-reactive, electropolished surfaces | 316L |

| Chemical Manufacturing | Handles high temperatures, pressures, and solvents | 304 or 316L |

| Food & Beverage | Hygienic, easy to clean, non-reactive | 304 or 316L |

Ready to optimize your lab processes with the right reactor? KINTEK specializes in high-performance lab equipment, including stainless steel reactors tailored for pharmaceutical, chemical, and food production needs. Our experts will help you select the ideal grade and configuration to ensure safety, efficiency, and product quality. Contact us today to discuss your specific requirements and discover how our solutions can enhance your workflow!

Visual Guide

Related Products

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- How does a high-pressure hydrothermal reactor facilitate the synthesis of mesoporous hydroxyapatite catalysts?

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis