At its core, an autoclave is an essential tool for achieving complete sterility. It is used across a wide range of professional fields to sterilize equipment like surgical instruments and laboratory glassware, decontaminate biohazardous waste, and perform specific industrial processes like curing materials. The device leverages high-pressure, superheated steam to destroy all forms of microbial life, including resilient bacteria, viruses, and spores that boiling water or chemical disinfectants cannot reliably eliminate.

An autoclave is not merely a high-powered cleaner; it is a validated sterilization device. Its primary function is to use pressurized steam to raise temperatures above boiling, ensuring the total destruction of all microorganisms on an object or within a substance.

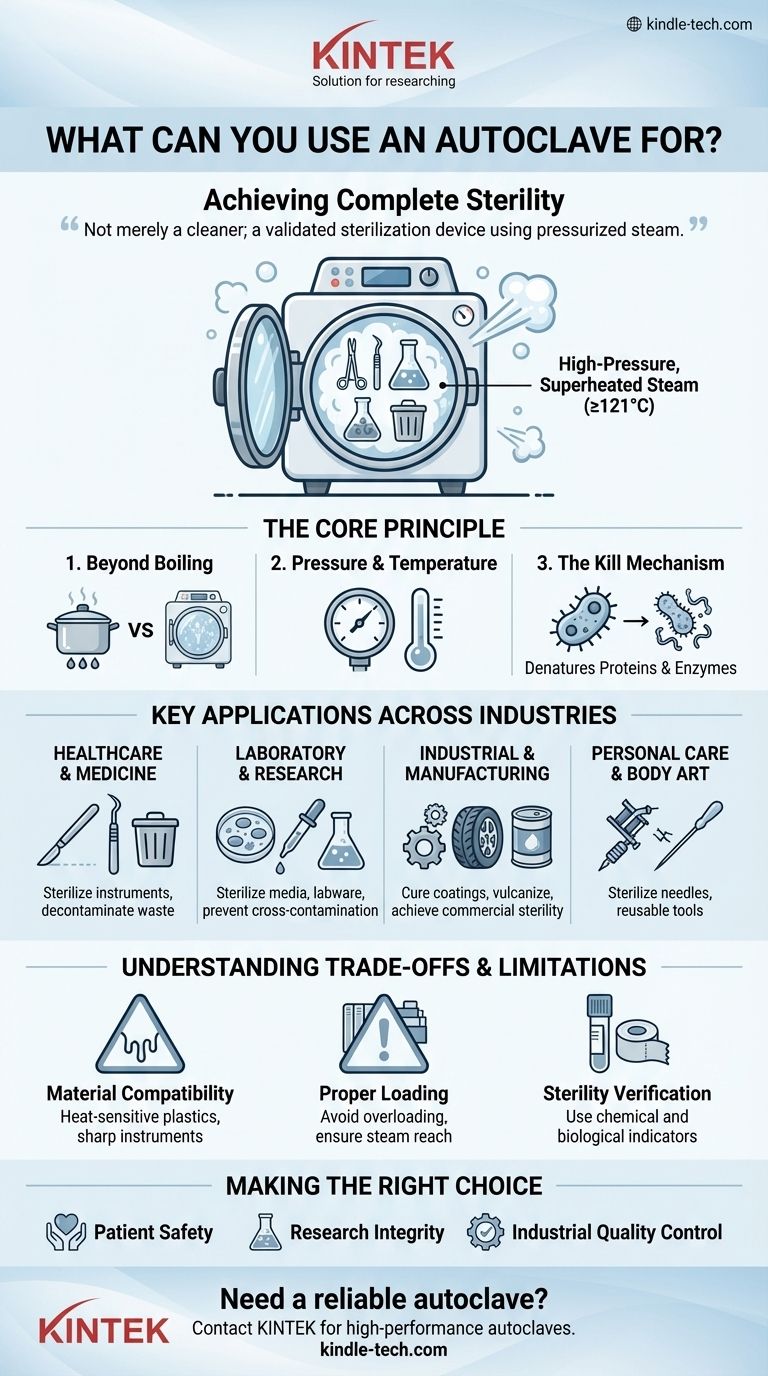

The Core Principle: Why Steam Sterilization is the Gold Standard

To understand an autoclave’s uses, you must first understand why it is so effective. Its power lies in the physics of steam under pressure.

Beyond Boiling and Wiping

Simple boiling or cleaning with detergents can remove or kill many common microbes. However, these methods are insufficient for eliminating highly resistant bacterial spores and certain viruses.

Achieving true sterility—the complete absence of viable microorganisms—requires a more powerful approach. This is the critical distinction for medical, laboratory, and other sensitive applications.

How It Works: Pressure and Temperature

An autoclave is a sealed chamber that works like a sophisticated pressure cooker. By increasing the internal pressure, it prevents water from boiling at its normal 100°C (212°F) point.

This allows the steam inside to reach much higher temperatures, typically 121°C (250°F) or higher. This superheated steam can penetrate materials and surfaces far more effectively than dry heat.

The Kill Mechanism

The combination of intense heat and moisture rapidly denatures essential proteins and enzymes within microbial cells, causing them to coagulate and die. This process is lethal to all forms of life, from simple bacteria to the toughest endospores.

Key Applications Across Industries

The ability to achieve verifiable sterility makes the autoclave indispensable in any field where microbial contamination is a critical risk.

Healthcare and Medicine

This is the most well-known application. Autoclaves are used to sterilize surgical and dental instruments, reusable medical devices, and implantable items. They are also used to decontaminate medical waste before it is discarded, preventing the spread of infectious agents.

Laboratory and Research

In microbiology, genetics, and life sciences, preventing cross-contamination is paramount. Autoclaves are used daily to sterilize culture media, solutions, glassware, pipette tips, and other laboratory equipment. They are also used to inactivate potentially hazardous biological materials before disposal.

Industrial and Manufacturing

The principles of steam sterilization extend beyond the lab and hospital. In the chemical industry, autoclaves are used to cure coatings, vulcanize rubber, and facilitate hydrothermal synthesis for growing crystals. In the food industry, they are used to achieve commercial sterility in canned goods.

Personal Care and Body Art

To ensure client safety and prevent infections, reputable tattoo studios, piercing shops, and beauty salons use autoclaves to sterilize needles, grips, and other reusable equipment. This is a critical standard of care in these professions.

Understanding the Trade-offs and Limitations

While powerful, an autoclave is not a universal solution. Understanding its limitations is key to using it safely and effectively.

Material Compatibility is Crucial

Not all materials can withstand the high heat and pressure. Heat-sensitive plastics will melt, sharp instruments can become dulled over time, and certain chemicals can release corrosive fumes. You must always confirm that an item is marked as "autoclavable."

Proper Loading and Operation Matter

Successful sterilization depends on steam reaching every surface. Overloading the chamber or packing items too tightly creates air pockets and cold spots where microbes can survive. Proper operation requires following validated cycles for different types of loads (e.g., liquids, solids, or wrapped instruments).

Sterility Must Be Verified

You cannot assume a cycle was successful simply because it ran. Chemical indicators (tape that changes color) and biological indicators (vials containing highly resistant spores) are used regularly to validate that the autoclave is functioning correctly and achieving true sterility.

Making the Right Choice for Your Goal

Your specific application will determine how you use an autoclave.

- If your primary focus is patient safety and infection control: Use it for the complete sterilization of all reusable surgical and medical instruments according to validated protocols.

- If your primary focus is research integrity: Use it to prepare sterile labware and media, and to safely decontaminate all biohazardous waste before disposal.

- If your primary focus is industrial quality control: Use it to perform material processing steps like curing or to ensure the commercial sterility of packaged products.

Ultimately, the autoclave is the definitive tool for any process that demands an absolute and verifiable absence of microbial life.

Summary Table:

| Application Area | Primary Use | Key Benefit |

|---|---|---|

| Healthcare & Medicine | Sterilize surgical instruments, decontaminate waste | Ensures patient safety and infection control |

| Laboratory & Research | Sterilize glassware, media, and biohazardous materials | Prevents cross-contamination for research integrity |

| Industrial & Manufacturing | Cure coatings, vulcanize rubber, process materials | Achieves commercial sterility and material quality |

| Personal Care & Body Art | Sterilize needles and reusable tools | Maintains client safety and professional standards |

Need a reliable autoclave for your sterilization needs? KINTEK specializes in high-performance lab equipment, including autoclaves designed for medical, laboratory, and industrial applications. Our solutions ensure precise temperature control, validated sterilization cycles, and durable performance to meet your specific requirements. Contact us today to find the perfect autoclave for your workflow and achieve complete, verifiable sterility!

Visual Guide

Related Products

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What is the benefit of autoclave? Achieve Rapid, Reliable Sterilization for Your Lab

- Are autoclave emissions hazardous? How to Safely Manage Steam, Biological, and Chemical Risks

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization

- What are the chambers of the autoclave? Understanding Single-Wall vs. Jacketed Designs

- What is the role of the Bowie-Dick-Test in waste decontamination? Focus on Lab Efficiency & Compliance

- What role does a PTFE-lined autoclave play in UIO-66 synthesis? Key Benefits for Pure MOF Nanocrystals

- Why are high-pressure digestion tanks essential for photocatalysts? Optimize Synthesis with Hydrothermal Autoclaves

- What function does a high-pressure laboratory autoclave serve in walnut shell pretreatment? Enhance Biomass Reactivity.