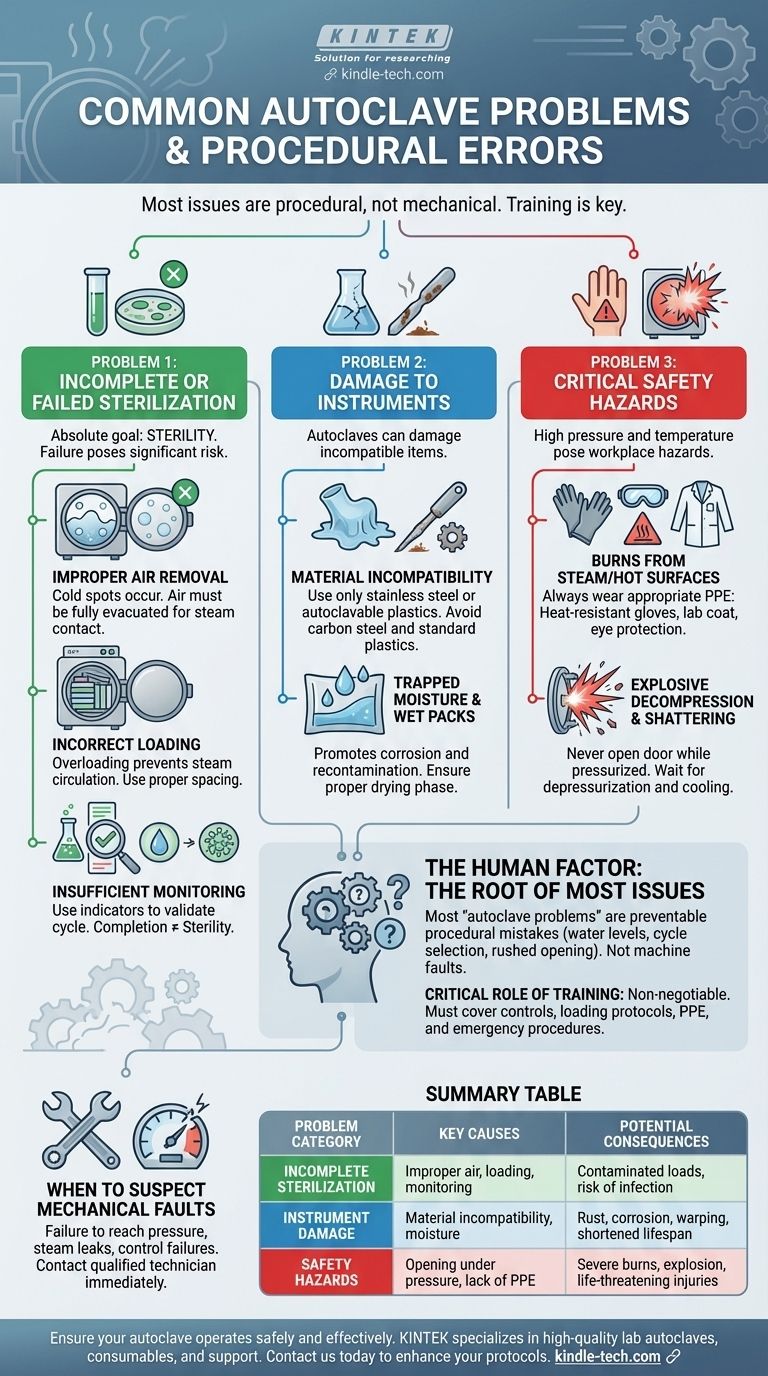

The most common problems encountered when using an autoclave are not mechanical failures, but procedural errors. These issues typically fall into three categories: incomplete sterilization of the load, damage to the instruments being processed, and significant safety hazards for the operator, such as severe burns or explosive decompression.

The vast majority of autoclave failures trace back to a single root cause: a deviation from established procedure. Understanding that these are primarily human-factor issues—related to loading, cycle selection, and safety protocols—is the key to operating an autoclave safely and effectively.

Problem 1: Incomplete or Failed Sterilization

The absolute goal of an autoclave is to achieve sterility. When this fails, the entire process is invalid, posing a significant risk in medical or research settings.

Cause: Improper Air Removal

Steam sterilization works on the principle of direct contact at a specific temperature and pressure. If air is not fully evacuated from the chamber, it creates "cold spots" where the temperature never reaches the required level for sterilization.

This is a frequent error when operators rush the initial venting phase, failing to allow the air-water mixture to escape completely before sealing the chamber.

Cause: Incorrect Loading

How you load the autoclave is as important as the cycle itself. Overloading the chamber prevents steam from circulating freely and reaching all surfaces.

Placing items in sealed or improper containers also blocks steam penetration. Instruments must be arranged to allow for maximum exposure, not packed tightly or stacked in a way that creates barriers.

Cause: Insufficient Monitoring

You cannot assume a cycle was successful simply because it completed. Best practice requires a monitoring protocol using chemical or biological indicators.

Failing to use these indicators means you have no objective proof that sterilization conditions were met inside the pack or load. Chemical indicators show temperature was reached, while biological indicators confirm that highly resistant bacterial spores have been killed.

Problem 2: Damage to Instruments and Equipment

An autoclave can easily damage the very items it is meant to sterilize if used improperly.

Cause: Material Incompatibility

Not all materials can withstand the high temperature, pressure, and moisture of an autoclave. The most common mistake is processing items that are not rated for autoclaving.

Carbon steel instruments will rust and corrode due to the high moisture content. Likewise, most standard plastics will melt or warp. Only use instruments made of stainless steel or plastics specifically designed for high-heat sterilization.

Cause: Trapped Moisture and Wet Packs

A proper autoclave cycle includes a drying phase. If items are removed while still wet, it creates two problems: it can promote corrosion on metal instruments and it creates a pathway for recontamination of the sterile pack.

This is often caused by improper loading that traps condensation or by cutting the drying cycle short.

Understanding the Trade-offs: User Error vs. Mechanical Failure

It is crucial to distinguish between a problem caused by the operator and a true malfunction of the machine.

The Human Factor: The Root of Most Issues

The majority of so-called "autoclave problems" are preventable procedural mistakes. These include failing to add the correct amount of water, choosing the wrong cycle for the load type, or attempting to open the door before the chamber has fully depressurized.

These errors are not faults of the machine but a failure in the operational workflow.

The Critical Role of Training

Because of the high potential for user error, no one should operate an autoclave without comprehensive training. This is non-negotiable.

Training must cover the function of all controls, proper loading and unloading protocols, required PPE (Personal Protective Equipment), and emergency procedures. Without this, errors are inevitable.

When to Suspect Mechanical Faults

True mechanical failures are less common but do occur. Signs include the autoclave failing to reach or maintain pressure, visible steam leaks from the door seal, or failure of control displays.

In these cases, the machine must be taken out of service immediately and reported for maintenance by a qualified technician.

Problem 3: Critical Safety Hazards

An autoclave pressurizes steam to extremely high temperatures, making it a significant workplace hazard if not respected.

Risk: Burns from Steam and Hot Surfaces

Severe burns are the most common injury associated with autoclave use. This can happen from touching the hot interior chamber or from contact with the superheated steam released when the door is opened.

Always wear appropriate PPE, including heat-resistant gloves, a lab coat, eye protection, and closed-toe shoes, especially when unloading.

Risk: Explosive Decompression and Shattering

Opening the door while the chamber is still pressurized can cause a violent, explosive release of steam and contents. This is a life-threatening risk.

Furthermore, opening the door too quickly even after depressurization can cause a rapid temperature change, leading to the shattering of glass containers or the boil-over of superheated liquids inside. Always allow the machine to cool and follow the manufacturer's specific unloading procedure.

Making the Right Choice for Your Goal

Your approach to using an autoclave should be guided by your primary objective, which is always rooted in safety and efficacy.

- If your primary focus is ensuring effective sterilization: You must validate every cycle with chemical and biological indicators and master proper loading techniques to ensure complete steam penetration.

- If your primary focus is operator safety: Mandate the use of proper PPE and enforce strict adherence to depressurization and cooling procedures before opening the door.

- If your primary focus is equipment longevity: Strictly process only autoclave-compatible materials and ensure loads are properly dried to prevent corrosion and recontamination.

By mastering procedure and treating the device with respect, the autoclave becomes one of the most reliable and essential tools in any laboratory or clinical setting.

Summary Table:

| Problem Category | Key Causes | Potential Consequences |

|---|---|---|

| Incomplete Sterilization | Improper air removal, incorrect loading, insufficient monitoring | Contaminated loads, invalid results, risk of infection |

| Instrument Damage | Material incompatibility, trapped moisture/wet packs | Rust, corrosion, warping, shortened equipment lifespan |

| Safety Hazards | Opening door under pressure, lack of PPE, explosive decompression | Severe burns, equipment shattering, life-threatening injuries |

Ensure your autoclave operates safely and effectively. Proper training and reliable equipment are essential for preventing sterilization failures and protecting your team. KINTEK specializes in high-quality lab autoclaves, consumables, and comprehensive support services tailored to laboratory needs. Contact us today (#ContactForm) to discuss how we can enhance your sterilization protocols and lab safety.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What are the do's and don'ts in using autoclave? A Guide to Safe and Effective Sterilization

- Why is autoclave better than dry-heat? Achieve Faster, More Efficient Sterilization

- What are the specifications for sterilization? Achieve Your Required Sterility Assurance Level (SAL)

- What are the limits of autoclave? Understanding Material and Operational Constraints

- What can you use instead of autoclave? Find the Right Sterilization Method for Your Materials

- What is the pressure required in an autoclave? Achieve Sterile Results with 15 PSI

- What is the purpose of inserting armored thermocouples into an autoclave? Precision in Ammonothermal Process