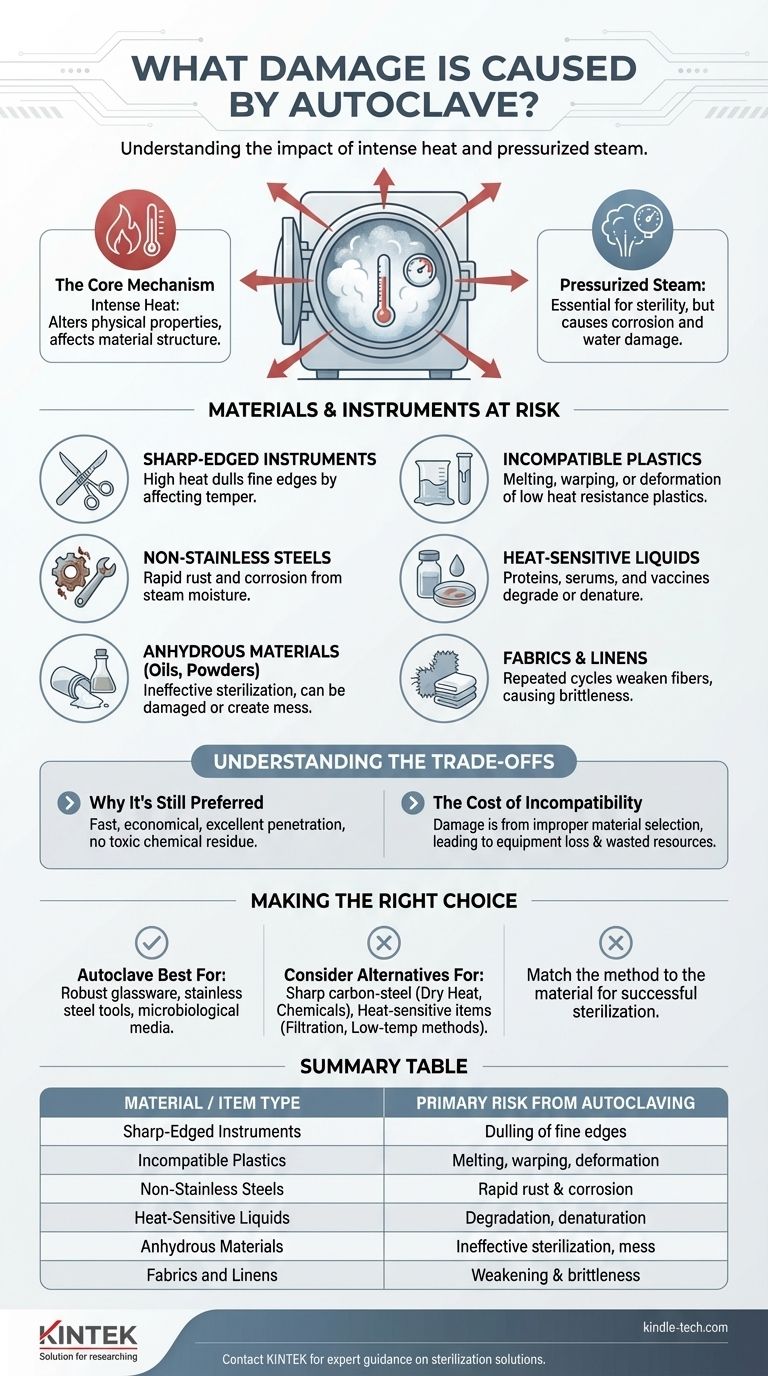

Autoclaving is a highly effective sterilization method, but its core mechanism—intense heat and pressurized steam—can cause significant damage. The primary risks include dulling sharp instruments, melting or warping incompatible plastics, corroding certain metals like carbon steel, and degrading heat-sensitive chemical and biological materials.

The fundamental issue is not a flaw in the autoclave itself, but a mismatch between the sterilization method and the material being processed. Damage occurs when an item cannot withstand the high temperatures and moisture required to achieve sterility.

The Root Cause: How an Autoclave Induces Damage

An autoclave achieves sterilization by subjecting its contents to high-pressure saturated steam at temperatures of 121°C (250°F) or higher. This combination is lethal to microorganisms but is inherently harsh on many materials.

Intense Heat

The high temperature is the most common source of damage. It can alter the physical properties of materials that are not specifically designed to withstand such thermal stress.

Pressurized Steam

Moisture is essential for the sterilization process, as it facilitates the coagulation of microbial proteins. However, this same moisture can be destructive, leading to corrosion and water damage on susceptible items.

Materials and Instruments at Risk

Understanding which materials are vulnerable is the key to preventing damage and ensuring both sterility and the longevity of your equipment.

Sharp-Edged Instruments

High heat can affect the temper of high-carbon steel, causing the fine, sharp edges on instruments like scalpels and some scissors to become dull and less effective.

Incompatible Plastics

Many common plastics have a melting point below standard autoclave temperatures. Only heat-resistant plastics, such as polypropylene (PP) and polycarbonate (PC), can be safely autoclaved. Others will melt, warp, or deform.

Non-Stainless Steels

While stainless steel is highly resistant to corrosion, standard carbon steel is not. The moisture from the steam will rapidly cause rust and corrosion on these instruments, compromising their integrity and function.

Heat-Sensitive Liquids and Biologicals

Many complex molecules cannot survive the autoclaving process. This includes certain high-protein solutions, vaccines, serums, and vitamins, which will degrade or denature, rendering them useless.

Anhydrous Materials (Oils and Powders)

Oily substances and powders cannot be sterilized effectively by an autoclave. The steam cannot penetrate these materials, and they can be damaged or create a mess within the chamber.

Fabrics and Linens

While some fabrics can be autoclaved, the process of repeated high-heat and moisture cycles can weaken the fibers over time, causing them to become brittle and tear easily.

Understanding the Trade-offs

Despite these risks, autoclaving remains a gold standard for sterilization in medical and laboratory settings for clear and compelling reasons.

Why It's Still the Preferred Method

The autoclave is fast, economical, and provides excellent penetration on all surfaces of suitable instruments. Critically, it achieves sterilization without the use of toxic chemicals, leaving behind no harmful residue.

The Cost of Incompatibility

The damage described is not a failure of the autoclave but a result of improper material selection. Attempting to autoclave an incompatible item leads directly to equipment loss, compromised experimental results, and wasted resources.

Making the Right Choice for Your Goal

Always verify an item's compatibility before placing it in an autoclave. When in doubt, consult the manufacturer's guidelines or choose an alternative method.

- If your primary focus is robust glassware, stainless steel tools, or microbiological media: The autoclave is your most reliable and efficient choice.

- If you are sterilizing sharp carbon-steel instruments: Consider dry heat or chemical sterilization to preserve the integrity of the cutting edge.

- If you are working with heat-sensitive plastics, serums, or protein solutions: You must use low-temperature methods like filtration or specific chemical sterilants to prevent degradation.

Successful sterilization is ultimately about matching the method to the material.

Summary Table:

| Material/Item Type | Primary Risk from Autoclaving |

|---|---|

| Sharp-Edged Instruments | Dulling of fine edges due to heat affecting temper |

| Incompatible Plastics | Melting, warping, or deformation |

| Non-Stainless Steels | Rapid rust and corrosion from moisture |

| Heat-Sensitive Liquids | Degradation or denaturation of proteins and molecules |

| Anhydrous Materials (Oils, Powders) | Ineffective sterilization and potential mess |

| Fabrics and Linens | Weakening and brittleness of fibers over time |

Protect your valuable lab equipment and ensure effective sterilization. Choosing the right method is critical for preserving your instruments and achieving reliable results. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the right sterilization equipment or alternative solutions to prevent autoclave damage. Contact KINTEL today for a consultation and keep your lab running safely and efficiently!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control