One of the most significant risks of using an autoclave is material damage. The high-temperature, pressurized steam that makes it an excellent sterilizer can also destroy or compromise items that are not suited for the process, such as heat-sensitive plastics, certain sharp carbon steel instruments, and oily or water-repellent substances. This makes material compatibility a critical safety and operational concern.

An autoclave is a powerful and economical sterilization tool, but its core risk lies in its limitations. Its reliance on high-heat steam means it is only suitable for heat-stable, water-penetrable items, and improper use poses significant risks to both the materials being sterilized and the operator.

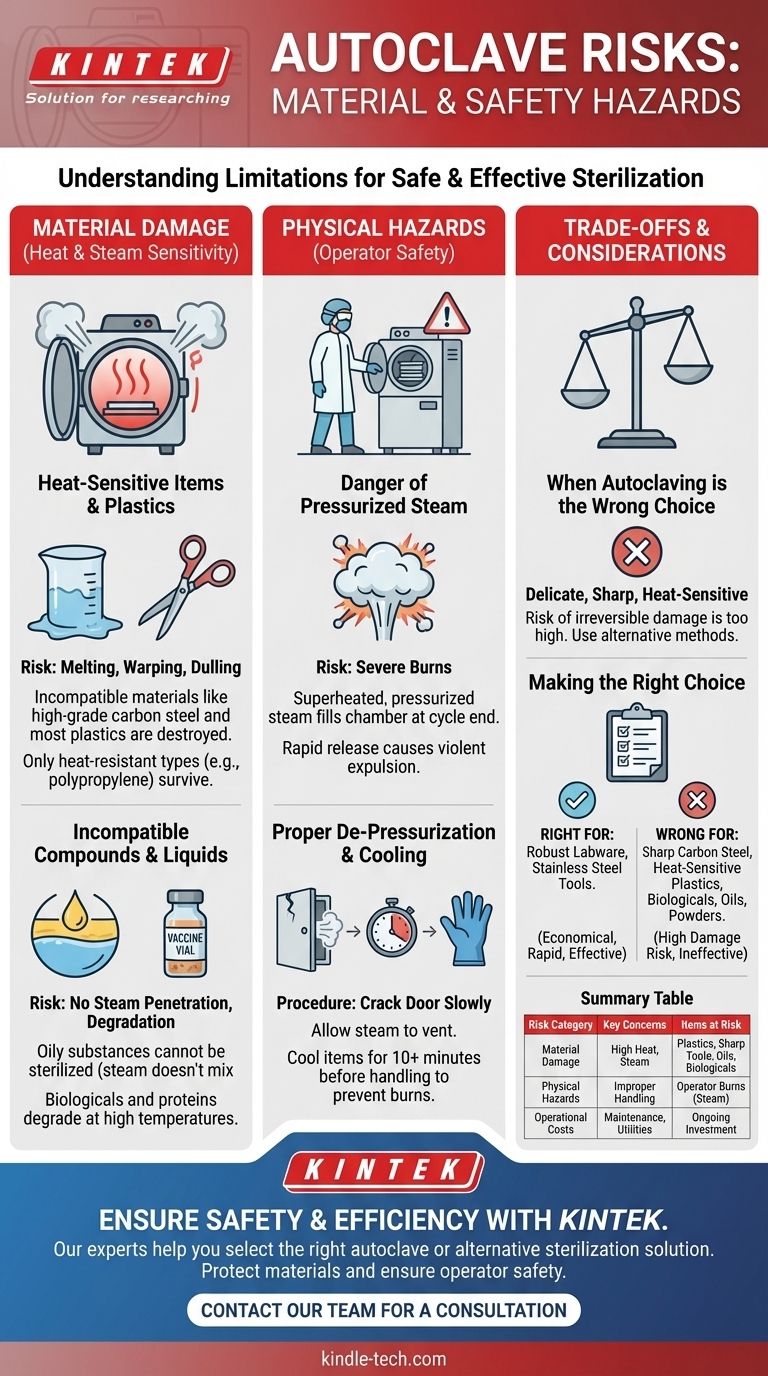

The Risk of Material Damage: Know What to Avoid

The fundamental principle of an autoclave is sterilization through superheated steam. If a material cannot withstand high temperatures or be properly penetrated by steam, it will be damaged or left unsterilized.

Heat-Sensitive Instruments and Plastics

Many materials are simply not designed for extreme heat. High-grade carbon steel, often used for sharp scissors and scalpel blades, will become dull and lose its edge under autoclave conditions.

Furthermore, many common plastics will melt or warp, rendering them useless. Only specific, heat-resistant plastics like polypropylene or polycarbonate can typically survive the process.

Incompatible Compounds and Liquids

An autoclave is ineffective for substances that steam cannot penetrate. Oily or greasy materials cannot be sterilized this way because water and oil do not mix, preventing the steam from making contact with all surfaces.

Likewise, certain biological compounds like vaccines, serums, or high-protein solutions will degrade or be destroyed by excessive heat, requiring alternative sterilization methods like filtration.

The Physical Risks of Operation

Beyond material damage, the operator faces direct physical hazards if proper procedures are not followed. The primary danger comes from the very element that makes the autoclave work: pressurized steam.

The Danger of Pressurized Steam

At the end of a cycle, the chamber is filled with superheated, pressurized steam that can cause severe burns upon release.

Opening the door too quickly or without care can result in a violent and dangerous expulsion of this steam directly at the operator.

Proper De-Pressurization and Cooling

Safe operation requires a methodical approach. The door should first be cracked open slightly, allowing the steam to vent slowly and safely.

After the steam has dissipated, which can take several minutes, the items must be left to cool for about 10 minutes before they can be handled safely.

Understanding the Trade-offs

While effective, an autoclave is not a universal solution. Recognizing its limitations is key to using it properly and deciding when an alternative is necessary.

When Autoclaving is the Wrong Choice

The primary trade-off is versatility. An autoclave's power comes with a strict set of rules about what it can process.

If your work involves delicate, sharp, or heat-sensitive materials, the risk of irreversible damage means an autoclave is not the appropriate tool.

Ongoing Operational Costs

The initial purchase price is only part of the investment. You must also account for ongoing costs related to maintenance, utility consumption, and sterility monitoring products to ensure the unit remains effective and safe.

Making the Right Sterilization Choice

Selecting the correct sterilization method requires matching the process to the material. An autoclave is highly effective, but only within its specific operational parameters.

- If your primary focus is sterilizing robust labware (like glassware) or stainless steel surgical tools: The autoclave is an economical, rapid, and highly effective choice.

- If your primary focus is sterilizing sharp carbon steel instruments or heat-sensitive plastics: The risk of damage is extremely high, and you should use a different method like chemical sterilization.

- If your primary focus is handling sensitive biological solutions, oils, or powders: Autoclaving is unsuitable due to material degradation and the inability of steam to penetrate these substances.

Understanding an autoclave's fundamental limitations is the key to ensuring both effective sterilization and operational safety.

Summary Table:

| Risk Category | Key Concerns | Materials/Items at Risk |

|---|---|---|

| Material Damage | High heat, pressurized steam | Heat-sensitive plastics, sharp carbon steel instruments, oily substances, sensitive biologicals |

| Physical Hazards | Improper handling, rapid depressurization | Operator risk of severe steam burns |

| Operational Costs | Maintenance, utilities, monitoring | Ongoing investment beyond initial purchase |

Ensure your lab's safety and efficiency with the right equipment from KINTEK.

Autoclaves are powerful, but using the wrong sterilization method can lead to damaged instruments and unsafe conditions. KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Our experts can help you select the perfect autoclave or recommend an alternative sterilization solution that protects your valuable materials and ensures operator safety.

Contact our team today for a personalized consultation and discover the KINTEK difference!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

People Also Ask

- What is the purpose of treating polyester fabric in an autoclave? Ensure Reliable Results in Lab Experiments

- How does a high-pressure rotary autoclave function during rice husk pretreatment? Optimize Biomass Conversion Efficiency

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- What are the 3 types of autoclave? Choose the Right Sterilization Method for Your Lab

- What are the advantages and disadvantages of sterilization with an autoclave? Achieve Reliable Sterilization for Your Lab

- What is the function of a Teflon-lined stainless steel autoclave in rGO/TiO2 synthesis? Key Role in Nanocomposites

- What should be autoclaved in a lab? A Guide to Safe and Effective Sterilization

- What are the factors for an autoclave to be effective? Master Time, Temperature, Pressure, and Steam Contact