At its core, a stainless steel reactor is a specialized, sealed vessel designed to contain and control chemical or biological processes. It is constructed from specific stainless steel alloys to provide a controlled environment—managing temperature, pressure, and mixing—while simultaneously resisting corrosion and ensuring the purity of the final product.

The true challenge is not simply knowing what a stainless steel reactor is, but understanding which specific grade of steel and reactor design is required for your process. Mismatched materials lead to contamination, equipment failure, and significant safety risks.

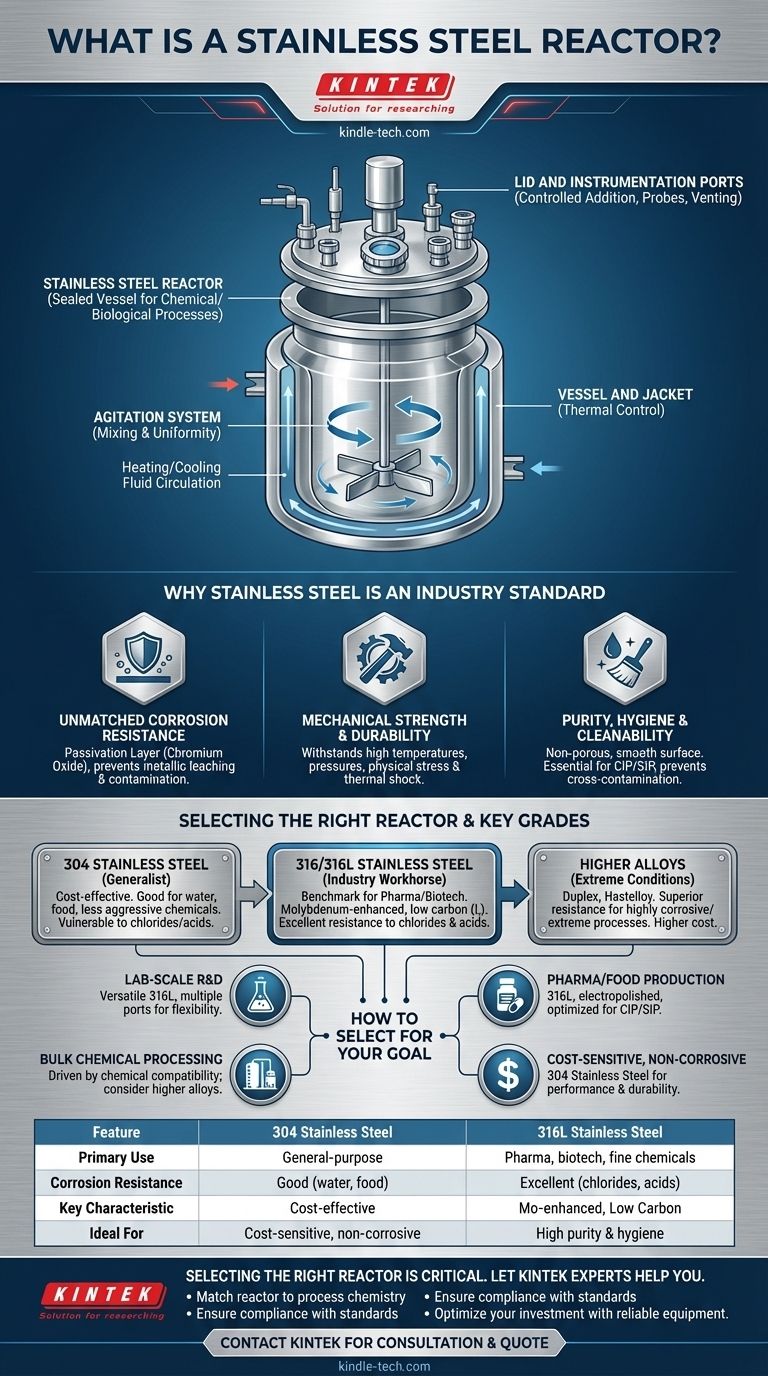

Why Stainless Steel is an Industry Standard

The dominance of stainless steel in reactor manufacturing is not accidental. It stems from a unique combination of properties that make it ideal for a vast range of sensitive and demanding applications.

Unmatched Corrosion Resistance

The primary advantage of stainless steel is its passivation layer. A thin, invisible layer of chromium oxide forms on the surface, protecting the underlying steel from reacting with the process fluids.

This self-repairing layer is critical for preventing metallic leaching, which would contaminate the product and degrade the vessel itself over time.

Mechanical Strength and Durability

Stainless steel maintains its structural integrity across a wide range of temperatures and pressures. This robustness is essential for safely containing exothermic reactions or operating under vacuum.

Unlike glass or polymer vessels, steel reactors can withstand significant physical stress and thermal shock, ensuring operational reliability and a long service life.

Purity, Hygiene, and Cleanability

The surface of high-quality stainless steel is non-porous and exceptionally smooth. This prevents materials from adhering to the walls and makes the vessel easy to clean and sterilize.

This characteristic is non-negotiable in the pharmaceutical, biotech, and food industries, where Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures are mandatory to prevent cross-contamination.

Key Components of a Reactor System

A reactor is more than just a tank. It is an integrated system where each component plays a critical role in controlling the process.

The Vessel and Jacket

The core of the system is the vessel body. Many reactors feature a jacketed design, which is a secondary shell around the main vessel. A thermal fluid (like water, oil, or steam) is circulated through this jacket to precisely heat or cool the contents.

The Agitation System

An agitator, driven by a motor, ensures the contents are properly mixed. This is vital for maintaining temperature uniformity, keeping solids suspended, and promoting efficient reactions.

The type of impeller (e.g., anchor, turbine, propeller) is selected based on the viscosity of the fluid and the specific mixing goal.

The Lid and Instrumentation Ports

The reactor lid is sealed to the vessel and is populated with various nozzles or ports. These allow for the controlled addition of reactants, the insertion of probes (for temperature, pH, pressure), and safe venting.

Understanding the Trade-offs and Key Grades

Choosing the right stainless steel is the most critical decision. Using the wrong grade is a common and costly mistake.

304 Stainless Steel: The Generalist

304 stainless steel is a cost-effective, general-purpose option with good corrosion resistance. It is suitable for applications involving water, food products, and less aggressive chemicals. However, it is vulnerable to chlorides and many acids.

316/316L Stainless Steel: The Industry Workhorse

316L stainless steel is the benchmark for most pharmaceutical, biotech, and fine chemical applications. The addition of molybdenum significantly enhances its resistance to chlorides and acids.

The "L" denotes low carbon content, which minimizes corrosion risk in welded areas—a critical feature for vessel integrity.

Higher Alloys: For Extreme Conditions

For processes involving highly corrosive chemicals, high temperatures, or extreme stress, more robust alloys are necessary. Duplex stainless steels or nickel-based alloys like Hastelloy offer superior resistance but come at a significantly higher cost. Choosing these is a matter of necessity, not preference.

How to Select the Right Reactor for Your Goal

The ideal reactor is one that meets the precise demands of your process without being over-engineered.

- If your primary focus is lab-scale R&D: A versatile, small-scale 316L reactor with multiple instrumentation ports offers the flexibility needed for experimentation.

- If your primary focus is pharmaceutical or food production: Prioritize a 316L reactor with a high-purity, electropolished surface finish and a design optimized for easy cleaning and sterilization (CIP/SIP).

- If your primary focus is bulk chemical processing: Your decision must be driven by rigorous chemical compatibility data; while 316L is a strong default, you may need to invest in higher-grade alloys for aggressive media.

- If your primary focus is a cost-sensitive, non-corrosive application: A 304 stainless steel reactor can provide the necessary performance and durability at a lower capital investment.

Ultimately, matching the reactor's material and design to your specific process chemistry is the most critical factor for ensuring safety, efficiency, and quality.

Summary Table:

| Feature | 304 Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Primary Use | General-purpose, less aggressive chemicals | Pharmaceutical, biotech, fine chemicals |

| Corrosion Resistance | Good for water, food products | Excellent; resistant to chlorides & acids |

| Key Characteristic | Cost-effective | Molybdenum-enhanced; low carbon for welding |

| Ideal For | Cost-sensitive, non-corrosive applications | Processes requiring high purity and hygiene |

Selecting the right reactor is critical to your process's success. The wrong material can lead to contamination, equipment failure, and safety risks. KINTEK specializes in providing high-quality stainless steel reactors and expert consultation to ensure your lab or production facility has the perfect equipment for its specific needs—from R&D to full-scale production.

Let our experts help you:

- Match the perfect reactor to your process chemistry and goals.

- Ensure compliance with industry standards for purity and safety.

- Optimize your investment with durable, reliable lab equipment.

Contact KINTEK today for a personalized consultation and quote!

Visual Guide

Related Products

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Laboratory High Pressure Vacuum Tube Furnace

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- What is the role of a high-pressure reactor in hydrothermal synthesis? Optimize Mesoporous Hydroxyapatite Production

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- How does a high-pressure hydrothermal reactor facilitate the synthesis of mesoporous hydroxyapatite catalysts?