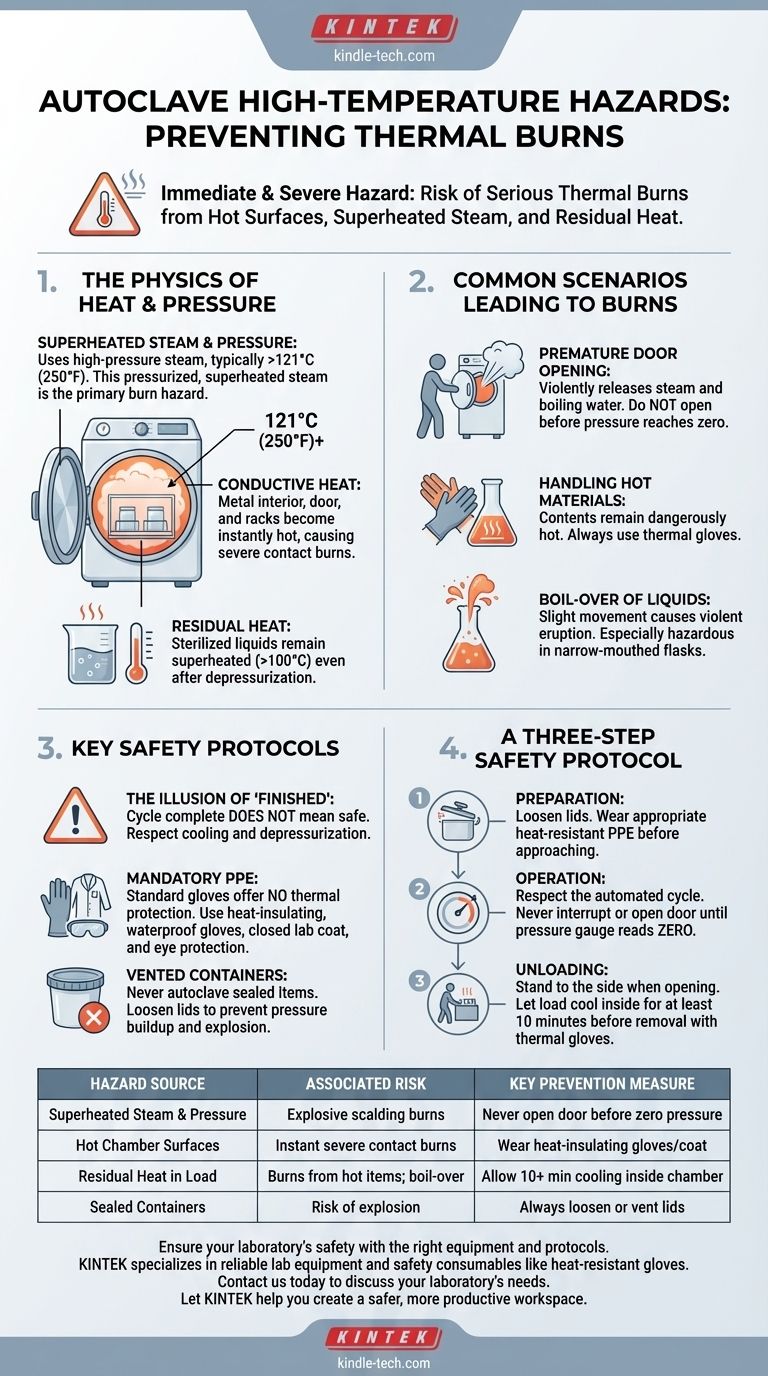

The most immediate and severe hazard associated with an autoclave's high temperatures is the risk of serious thermal burns. These injuries can be caused by direct contact with the hot metal surfaces of the chamber, the explosive release of superheated steam, or by handling sterilized materials that have not adequately cooled.

The core danger of an autoclave isn't just the visible hot surfaces; it's the invisible, high-energy steam and the significant heat retained within the sterilized load long after a cycle completes. Understanding and respecting these distinct heat sources is critical for safe operation.

The Physics Behind High-Temperature Hazards

To prevent injury, it is essential to understand how an autoclave uses heat and pressure. The danger is multi-faceted and extends beyond what is immediately obvious.

Superheated Steam and Pressure

An autoclave is not simply a hot oven; it is a pressure chamber. It uses high-pressure steam to achieve sterilization temperatures, typically 121°C (250°F) or higher, which is well above the normal boiling point of water. This pressurized, superheated steam is the primary burn hazard.

Conductive Heat Transfer

During a cycle, the entire apparatus becomes extremely hot. The metal walls of the interior chamber, the door, and any racks or trays inside will reach the sterilization temperature and can cause severe contact burns instantly.

Residual Heat in Sterilized Loads

The items you sterilize absorb a tremendous amount of thermal energy. Liquids, in particular, pose a significant risk as they can remain superheated—at a temperature above their normal boiling point—even after the chamber has depressurized.

Common Scenarios Leading to Burns

Most heat-related injuries from autoclaves are not random accidents; they result from predictable and preventable procedural errors.

Premature Door Opening

Opening the door before the chamber has fully depressurized and cooled is the most common cause of serious injury. This action can cause a violent, explosive release of steam and boiling water directly at the operator.

Handling Hot Materials

Even after a successful cycle and a cool-down period, the contents can remain dangerously hot for a long time. Attempting to remove glassware, instruments, or waste without proper thermal gloves is a frequent source of severe burns.

Boil-over of Superheated Liquids

Superheated liquids are deceptively stable inside the autoclave. However, a slight jolt or movement when removing them can cause the liquid to erupt violently from its container, leading to scalding burns. This is especially true for liquids in narrow-mouthed flasks.

Understanding the Key Safety Protocols

Effective safety is not about speed; it's about a disciplined, methodical approach that accounts for the inherent thermal hazards.

The Illusion of a "Finished" Cycle

The audible alarm or "cycle complete" display only indicates that the sterilization phase is over. It does not mean the contents are safe to handle. The cooling and depressurization period is a critical part of the safety process and must not be bypassed.

The Necessity of Correct PPE

Standard lab gloves, like latex or nitrile, offer zero protection from thermal hazards. Proper Personal Protective Equipment (PPE) is non-negotiable and must include:

- A closed lab coat

- Splash-proof eye protection

- Heat-insulating, waterproof gloves that extend to cover the forearm

The Danger of Sealed Containers

Never autoclave a container with a tightly sealed lid. The extreme heat will cause the pressure inside the container to build, creating a risk of explosion during the cycle or upon opening the autoclave door. Lids should always be loosened or vented.

A Three-Step Protocol for Safe Operation

To mitigate these heat-related hazards, you must treat the entire process—before, during, and after the cycle—with equal caution.

- If your primary focus is Preparation: Ensure all materials are loaded correctly with lids loosened, and always wear the appropriate heat-resistant PPE before you even approach the machine.

- If your primary focus is Operation: Respect the machine's automated cycle. Never attempt to interrupt it or open the door until the chamber pressure gauge reads zero and the designated cooling period is complete.

- If your primary focus is Unloading: Stand to the side of the door when opening it to avoid residual steam. Let the load cool inside the chamber for at least 10 minutes after opening the door before attempting removal with thermal gloves.

Treating every autoclave cycle with a deliberate, safety-first mindset is the definitive way to prevent high-temperature injuries.

Summary Table:

| Hazard Source | Associated Risk | Key Prevention Measure |

|---|---|---|

| Superheated Steam & Pressure | Explosive release causing scalding burns | Never open door before pressure is zero |

| Hot Chamber Surfaces | Instant, severe contact burns | Wear heat-insulating gloves and lab coat |

| Residual Heat in Load | Burns from handling hot items; boil-over of liquids | Allow load to cool inside chamber for 10+ minutes |

| Sealed Containers | Risk of explosion from pressure buildup | Always loosen or vent container lids before sterilizing |

Ensure your laboratory's safety with the right equipment and protocols.

Autoclaves are essential for sterilization, but managing their high-temperature hazards is critical for protecting your team. KINTEK specializes in providing reliable lab equipment, including autoclaves, and the necessary safety consumables like heat-resistant gloves. Our expertise ensures you have the tools and knowledge to operate safely and efficiently.

Contact us today to discuss your laboratory's needs. Let KINTEK help you create a safer, more productive workspace.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why do we autoclave at 121 degree Celsius? The Science Behind Sterilization

- Can you sterilize without autoclave? Yes, and Here's How to Choose the Right Method

- What are the methods of validation of autoclave? Ensure Sterility with a 3-Pillar Approach

- How do you maintain an autoclave in a lab? A Complete Guide to Safety and Reliability

- How is temperature controlled in autoclave? Master the Link Between Pressure and Sterilization

- Why is a High-temperature and High-pressure Autoclave necessary for zirconium alloy testing? Ensure Nuclear Safety.

- What equipment can be autoclaved? A Guide to Material Compatibility and Sterilization

- What is the function of high-pressure autoclaves in LH synthesis of zeolite membranes? Key Roles & Benefits