An electric mixer is most commonly called either a hand mixer or a stand mixer, depending on its design and function. While both use a motor to rotate attachments for mixing ingredients, a hand mixer is a portable, handheld device, whereas a stand mixer is a larger, stationary countertop appliance.

While the general term is simply "electric mixer," the specific name—hand mixer or stand mixer—reveals its intended use, power, and capacity. Understanding this distinction is the key to choosing the right tool for your task.

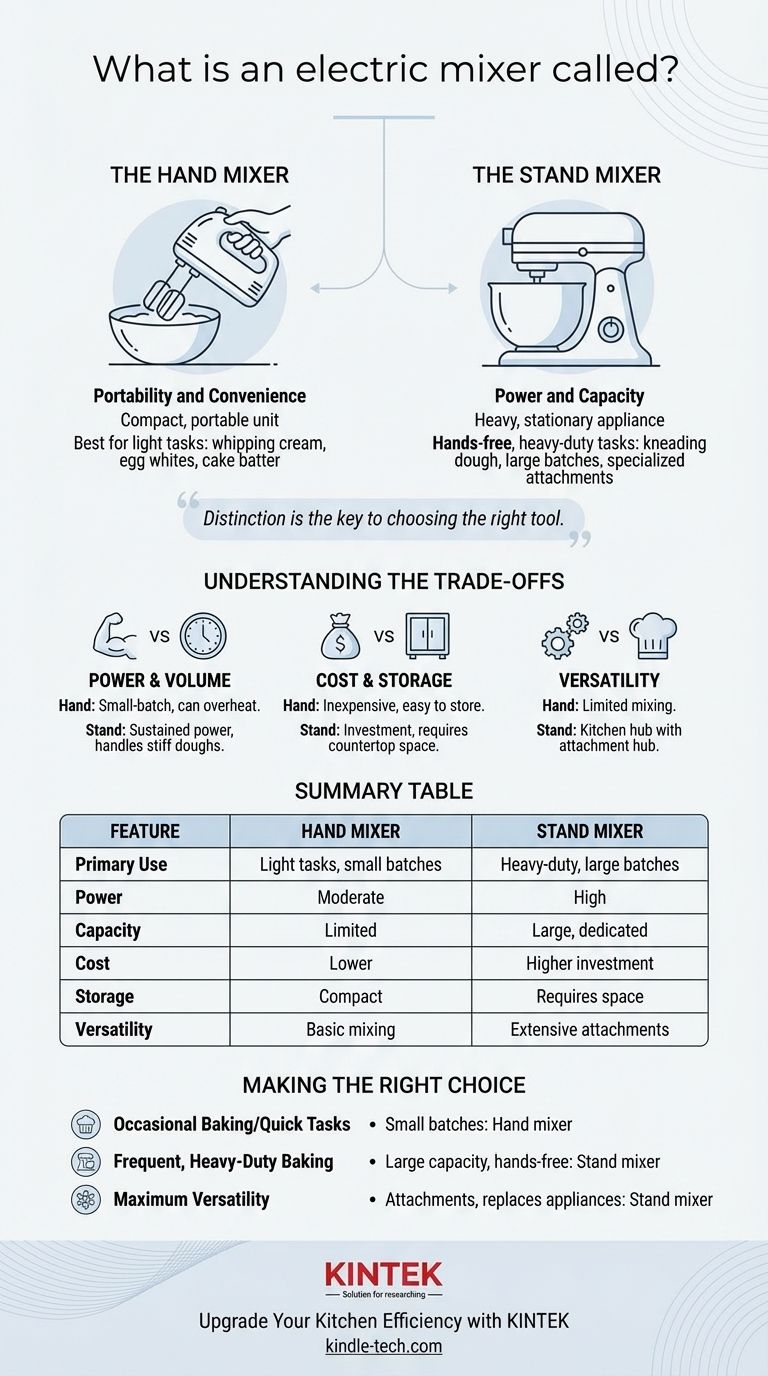

The Two Primary Types of Electric Mixers

The name of an electric mixer is directly tied to its form factor. This design dictates everything from its power to the types of jobs it can handle.

The Hand Mixer: Portability and Convenience

A hand mixer is a compact, portable motorized unit that you hold over a bowl. It uses two removable beaters that rotate to combine ingredients.

These devices are designed for lighter tasks. They excel at whipping cream or egg whites, mixing cake batters, and making frosting. They are the direct, powered evolution of the manual eggbeater.

The Stand Mixer: Power and Capacity

A stand mixer is a more powerful, stationary appliance. It features a heavy base, a motor housed in an overhead arm, and a dedicated mixing bowl that locks into place.

This hands-free design and powerful motor make it the ideal tool for heavy-duty or prolonged tasks, such as kneading bread dough, mixing large batches of stiff cookie dough, or using specialized attachments.

Understanding the Trade-offs

Choosing between a hand mixer and a stand mixer involves a clear set of trade-offs related to power, cost, and storage.

Power and Volume

A hand mixer is perfect for quick, small-batch jobs but its motor can overheat with dense mixtures like bread dough.

A stand mixer is built for sustained power. Its robust motor can handle very stiff doughs and large volumes without strain, making it essential for serious bakers.

Cost and Storage Space

Hand mixers are relatively inexpensive and small. They can be easily stored in a drawer or cabinet, making them ideal for kitchens with limited space.

Stand mixers represent a more significant financial investment and require dedicated countertop or substantial cabinet space due to their size and weight.

Versatility

A hand mixer is typically limited to its primary function of mixing with standard beaters and occasionally dough hooks.

A stand mixer is a versatile kitchen hub. Most models have a power take-off (PTO) hub that can run dozens of different attachments, from pasta rollers and meat grinders to spiralizers and grain mills.

Making the Right Choice for Your Goal

Your culinary needs will determine which type of mixer is the right fit for your kitchen.

- If your primary focus is occasional baking and quick tasks: A hand mixer offers the best balance of convenience, cost, and performance for small batches.

- If your primary focus is frequent, heavy-duty baking: A stand mixer is the necessary investment for its superior power, hands-free operation, and large capacity.

- If your primary focus is maximum kitchen versatility: The stand mixer, with its ecosystem of attachments, is an unparalleled tool that can replace multiple other appliances.

Ultimately, knowing the correct term for each mixer is the first step in selecting the precise tool to match your culinary ambitions.

Summary Table:

| Feature | Hand Mixer | Stand Mixer |

|---|---|---|

| Primary Use | Light tasks, small batches | Heavy-duty, large batches |

| Power | Moderate, can overheat with dense doughs | High, handles stiff doughs with ease |

| Capacity | Limited by bowl size | Large, dedicated mixing bowl |

| Cost | Lower | Higher investment |

| Storage | Compact, easy to store | Requires countertop or significant space |

| Versatility | Basic mixing functions | Extensive attachments (pasta makers, grinders, etc.) |

Upgrade Your Kitchen Efficiency with KINTEK

Whether you're a home baker or a professional chef, having the right equipment is crucial for perfect results. At KINTEK, we specialize in high-quality lab equipment and consumables, ensuring precision and reliability for all your mixing and preparation needs.

Let us help you find the ideal solution for your kitchen or laboratory. Contact us today to discuss your requirements and discover how our products can enhance your workflow!

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Oscillating Orbital Shaker

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What is the difference between a shaker and a vortex? Choose the Right Mixer for Your Lab Workflow

- Why is a high-precision orbital shaker required for chitin adsorption? Achieve Rapid Equilibrium & Precise Data

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance