In any modern heating or cooling system, condensation tubing is the dedicated drain line responsible for safely channeling water away from the appliance. This component, often a simple PVC or flexible vinyl pipe, collects the moisture that naturally forms during the operation of an air conditioner, dehumidifier, or high-efficiency condensing furnace. Its primary job is to prevent this water from backing up, overflowing, and causing damage to your system or home.

While it appears to be a minor part, the condensation tubing is a critical artery for your system. A failure in this simple tube is one of the most common reasons for a complete HVAC shutdown or a call for expensive water damage repairs.

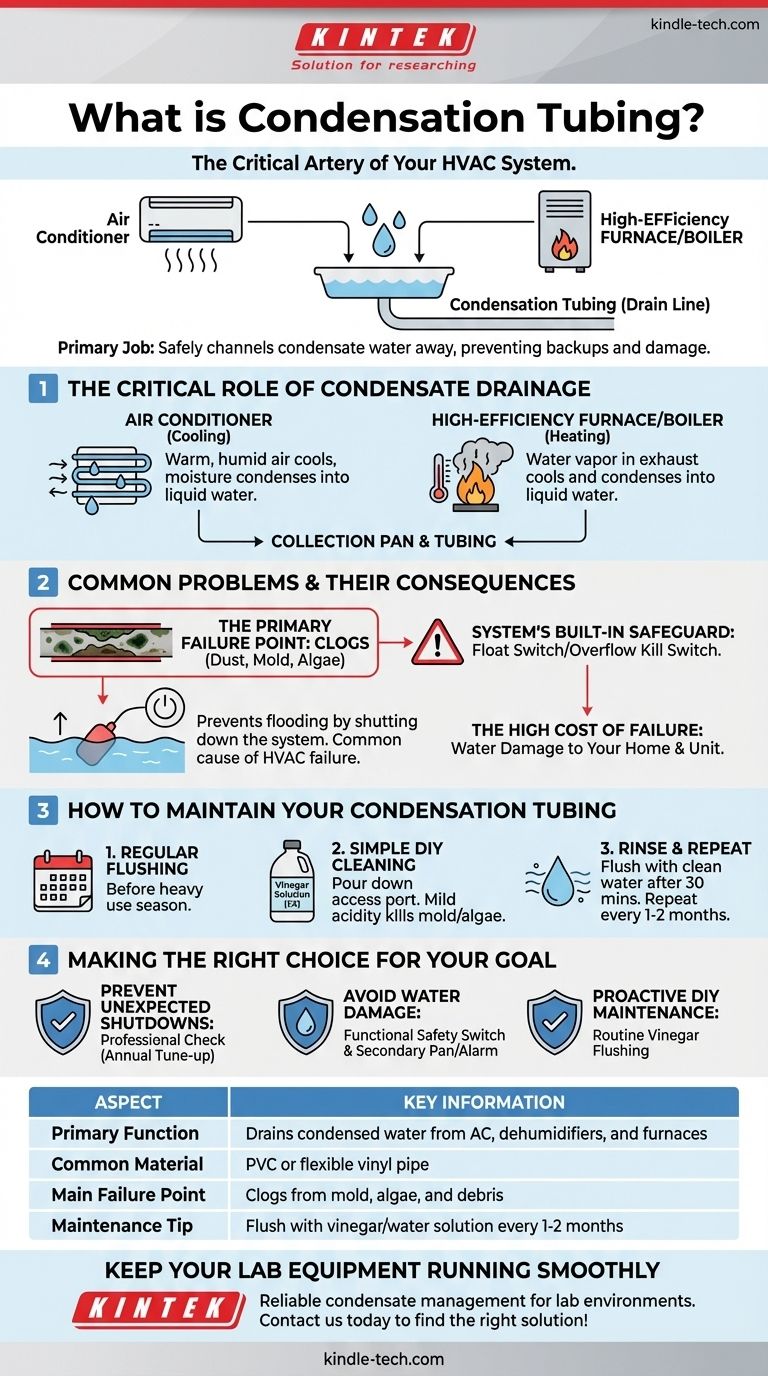

The Critical Role of Condensate Drainage

To understand the tubing, you first have to understand why the water—known as condensate—is there in the first place. This process is a fundamental part of how your equipment functions.

Why Condensation Forms

For an air conditioner, warm, humid air from your home is pulled across a very cold set of metal coils called the evaporator coil. As the air rapidly cools, the moisture it holds condenses into liquid water, much like water droplets forming on a cold glass of iced tea on a summer day.

For a high-efficiency furnace or boiler, hot exhaust gases, which are full of water vapor from the combustion process, pass through a secondary heat exchanger. This process extracts so much heat that the vapor cools and condenses back into liquid water before it leaves your home.

The Tubing's Sole Purpose

In both cases, this collected water drips into a collection pan. The condensation tubing, or condensate drain line, is the simple but essential pipe that connects to this pan. It uses gravity to carry the water safely away from the unit to a suitable disposal point, such as a floor drain, sump pump, or utility sink.

Common Problems and Their Consequences

The dark, damp environment inside a condensate line is a perfect breeding ground for problems. Ignoring this component is the root cause of many system failures.

The Primary Failure Point: Clogs

Over time, dust, debris, mold, and algae can build up inside the tube, forming a sludge that creates a blockage. This is the single most common failure point for any condensate drain system. When the pipe is clogged, water has nowhere to go.

The System's Built-in Safeguard

Most modern systems have a safety feature to prevent a flood from a clogged line. A small float switch or overflow kill switch is installed in the drain line or pan. If water backs up and rises to a certain level, it lifts the float, which triggers a switch that immediately shuts down your entire HVAC system.

This is why a system that suddenly won't turn on is often caused by a simple clogged drain line, not a major mechanical failure.

The High Cost of Failure

If this safety switch is absent or fails, the drain pan will continue to fill until it overflows. This can lead to significant and costly water damage to ceilings, walls, floors, and the furnace or air handler itself.

How to Maintain Your Condensation Tubing

Preventative maintenance is straightforward and is the key to avoiding system shutdowns and damage.

The Importance of Regular Flushing

The most effective way to prevent clogs is to flush the line periodically, especially before the start of the heavy use season (e.g., spring for AC, fall for heating). This simple task removes the beginnings of any potential sludge or buildup.

A Simple DIY Cleaning Method

For most systems, you can perform this maintenance yourself. Locate the drain line where it leaves the indoor unit and find the access port, which is often a T-shaped fitting with a removable cap.

Slowly pour a solution of one part distilled white vinegar and three parts water down the line. The mild acidity of the vinegar helps kill the mold and algae that cause clogs. After letting it sit for about 30 minutes, flush the line with clean water.

Making the Right Choice for Your Goal

Your approach to condensate management is a key factor in your system's overall reliability.

- If your primary focus is preventing unexpected shutdowns: Have a professional check and clear your condensate line as part of your annual HVAC tune-up.

- If your primary focus is avoiding water damage: Verify that your system has a functional overflow safety switch and consider installing a secondary drain pan with a water alarm for ultimate peace of mind.

- If your primary focus is proactive DIY maintenance: Routinely flush the line with a diluted vinegar solution every 1-2 months during peak season to keep it clear.

Properly managing this simple tube empowers you to prevent some of the most common and frustrating HVAC system failures.

Summary Table:

| Aspect | Key Information |

|---|---|

| Primary Function | Drains condensed water from AC, dehumidifiers, and high-efficiency furnaces |

| Common Material | PVC or flexible vinyl pipe |

| Main Failure Point | Clogs from mold, algae, and debris |

| Maintenance Tip | Flush with vinegar/water solution every 1-2 months during peak season |

Keep your lab equipment running smoothly with reliable condensate management solutions.

KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and reliability. Whether you're maintaining HVAC systems for climate-controlled environments or need durable tubing for laboratory applications, our products ensure peak performance and prevent costly downtime.

Contact us today to find the right condensate management solutions for your lab!

Visual Guide

Related Products

- Vacuum Cold Trap Direct Cold Trap Chiller

- Hexagonal Boron Nitride HBN Thermocouple Protection Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

People Also Ask

- What is the future scope of pyrolysis? Unlocking Circular Economy Potential with Waste-to-Resource Tech

- What can you make with an injection moulding machine? Mass-Produce High-Quality Plastic Parts Efficiently

- What is the effect of sintering temperature? Master the Key to Material Density and Strength

- What is the difference between a furnace and an oven in a laboratory? Choose the Right Tool for Your Lab's Heat Needs

- What are five applications of soldering? From Electronics to Art, Master Material Joining

- What is the importance of a magnetic stirrer in electrochemical acrylic acid degradation? Optimize Mass Transfer

- What is the difference between RF and DC sputtering? Choose the Right Method for Your Material

- Why is a high-precision orbital shaker required for chitin adsorption? Achieve Rapid Equilibrium & Precise Data