At its core, a laboratory autoclave is a high-pressure sterilization chamber. It uses pressurized, high-temperature steam to kill all microbial life—including bacteria, viruses, fungi, and spores—on equipment, in liquids, and within waste materials. This process makes it an indispensable tool for preventing contamination and ensuring safety in any biological or medical research setting.

The critical insight is that an autoclave's power comes not just from heat, but from pressurized steam. By increasing the pressure, water can be heated far beyond its normal 100°C boiling point, allowing the steam to rapidly penetrate materials and destroy even the most resilient microorganisms.

How an Autoclave Achieves Sterilization

Understanding the principles behind autoclaving is key to using it effectively. The process is far more sophisticated than simply heating items in an oven.

The Role of Pressurized Steam

The autoclave chamber is a sealed vessel. As water inside is heated, it turns to steam, and because the steam cannot escape, the pressure inside the chamber rises.

This pressure allows the steam to reach temperatures of 121°C (250°F) or higher. This superheated steam is the active sterilizing agent.

Why Steam is More Effective Than Dry Heat

Moist heat is significantly more efficient at transferring thermal energy than dry heat.

The steam condenses on cooler items placed inside the autoclave, releasing a large amount of energy directly onto their surfaces. This process rapidly denatures the essential proteins and enzymes that microorganisms need to survive and reproduce.

The Critical Sterilization Cycle

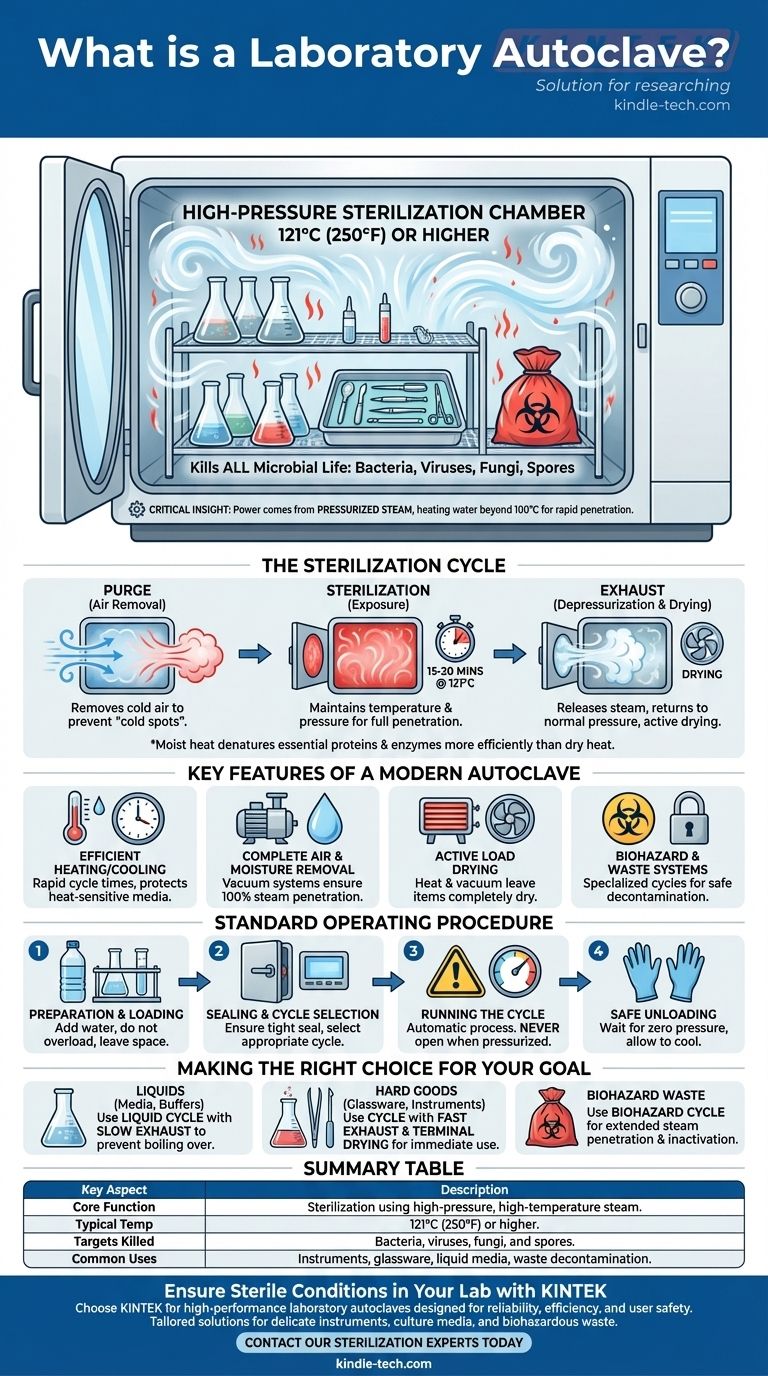

A typical autoclave cycle consists of three main phases:

- Purge (Air Removal): The machine removes cooler, ambient air from the chamber. Trapped air can create "cold spots" where steam cannot reach, leading to sterilization failure.

- Sterilization (Exposure): The chamber is held at the set temperature and pressure (e.g., 121°C for 15-20 minutes) to ensure the steam fully penetrates the entire load.

- Exhaust (Depressurization): The steam is released, the pressure returns to normal, and a drying phase often begins to remove residual moisture.

Key Features of a Modern Laboratory Autoclave

While the basic principle is universal, modern autoclaves incorporate features designed for efficiency, safety, and reliability.

Efficient Heating and Cooling

The ability to heat up quickly and cool down rapidly (fast cooling) reduces the total cycle time. This increases laboratory throughput and protects heat-sensitive media from prolonged exposure to high temperatures.

Complete Air and Moisture Removal

Effective sterilization depends on 100% steam penetration. Advanced autoclaves use vacuum systems or repeated steam flushes to ensure all air is removed before the sterilization phase begins, eliminating the risk of failed cycles.

Active Load Drying

For sterilizing instruments, glassware, or wrapped items, a wet load is a source of re-contamination. Modern systems incorporate active drying, often using heat and a vacuum, to ensure every item emerges completely dry and ready for use or storage.

Biohazard and Waste Systems

Autoclaves used for decontaminating laboratory waste have specialized cycles and containment features. These ensure that biohazardous materials are thoroughly sterilized before disposal, protecting both personnel and the environment.

The Standard Operating Procedure

Following a consistent procedure is critical for safety and achieving reliable sterilization.

1. Preparation and Loading

First, add the correct amount of deionized or distilled water. Then, place the items to be sterilized inside, ensuring you do not overload the chamber. Leave space between items to allow for proper steam circulation.

2. Sealing and Cycle Selection

Close the autoclave door, ensuring it is tightly sealed and the safety clamps are engaged. For automatic models, select the appropriate pre-programmed cycle for your load (e.g., liquids, glassware, or waste). For manual models, set the desired time and temperature.

3. Running the Cycle

Once started, the autoclave runs automatically. The chamber will pressurize and heat up, hold at the sterilization temperature, and then depressurize and cool down. Never attempt to open the door while the chamber is pressurized.

4. Safe Unloading

Wait for the cycle to complete and for the pressure gauge to read zero. Allow the load to cool for several minutes before opening the door to avoid steam burns or shattering superheated glassware. After use, the machine should be cleaned and powered down if not in continuous use.

Making the Right Choice for Your Goal

The type of load dictates the type of cycle you should use to ensure both safety and successful sterilization.

- If your primary focus is sterilizing liquids (media, buffers): Use a dedicated liquid cycle with a slow exhaust phase to prevent the liquids from boiling over during depressurization.

- If your primary focus is sterilizing hard goods (glassware, instruments): Use a cycle with a fast exhaust and a terminal drying phase to ensure items are dry and ready for immediate use.

- If your primary focus is decontaminating biohazardous waste: Use a specific biohazard cycle that ensures sufficient time for steam to penetrate the entire waste load for complete inactivation.

Mastering the principles of autoclaving is fundamental to achieving safe, reliable, and reproducible scientific results.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Sterilization using high-pressure, high-temperature steam. |

| Typical Sterilization Temperature | 121°C (250°F) or higher. |

| Targets Killed | Bacteria, viruses, fungi, and spores. |

| Common Uses | Sterilizing instruments, glassware, liquid media, and decontaminating waste. |

Ensure Sterile Conditions in Your Lab with KINTEK

Choosing the right autoclave is critical for the safety and integrity of your research. KINTEK specializes in high-performance laboratory autoclaves designed for reliability, efficiency, and user safety. Whether you need to sterilize delicate instruments, prepare culture media, or safely decontaminate biohazardous waste, our solutions are tailored to meet the rigorous demands of your laboratory.

Contact our sterilization experts today to find the perfect autoclave solution for your specific needs and ensure uncompromising sterility in your workflows.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- Why is the prevention of air entrapment critical for the autoclave sterilization process? Ensure 100% Sterility Today

- What is the primary purpose of an autoclave in the preparation of media for the biological leaching of uranium?

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- How should solid materials in bags be prepared for decontamination? Master Steam Penetration for Safe Sterilization

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity