At its core, metal sputtering is a physical vapor deposition (PVD) method used to apply exceptionally thin and uniform coatings. It operates within a vacuum by bombarding a solid source material, known as the target, with energetic ions from a plasma. This high-energy collision physically knocks atoms off the target, which then travel and deposit onto a substrate, forming a dense, high-quality film.

Sputtering is best understood not as a chemical or heat-based process, but as a highly controlled, atomic-scale construction technique. It uses the physical momentum of ions in a plasma to disassemble a source material atom by atom and reassemble it as a pristine film on a new surface.

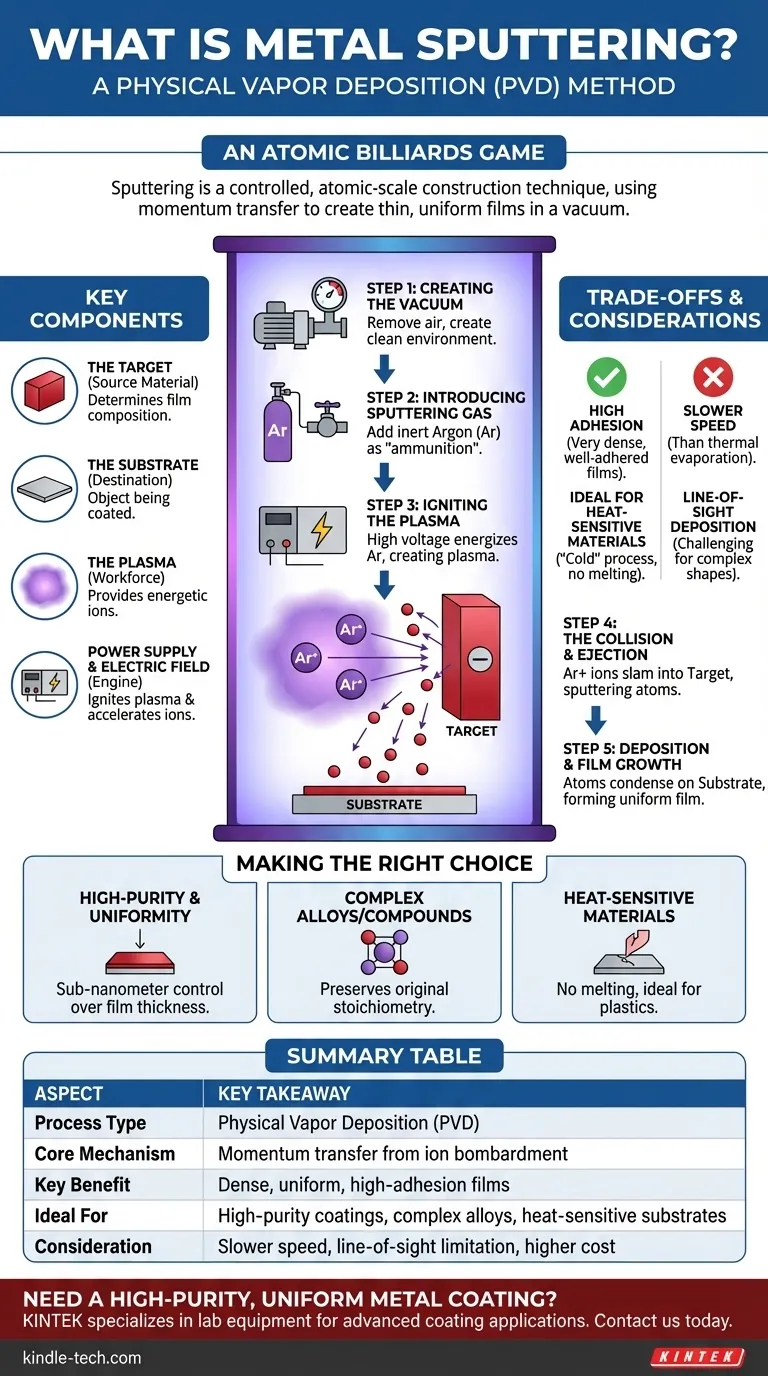

How Sputtering Works: An Atomic Billiards Game

Sputtering is a precise, multi-step process that takes place inside a sealed vacuum chamber. The core principle is momentum transfer, where one particle hits another and forces it to move.

Step 1: Creating the Vacuum Environment

First, the target (the metal to be sputtered) and the substrate (the object to be coated) are placed inside a chamber. Nearly all the air is pumped out to create a vacuum.

This vacuum is critical because it removes atmospheric gases that could contaminate the film and ensures the sputtered atoms can travel freely from the target to the substrate without colliding with unwanted particles.

Step 2: Introducing the Sputtering Gas

A small, precisely controlled amount of an inert gas, typically argon (Ar), is then introduced into the chamber. This gas is not reactive and will serve as the "ammunition" for the process.

Step 3: Igniting the Plasma

A high voltage is applied between the target and the substrate, with the target acting as the negative electrode (cathode). This strong electric field energizes the argon gas.

The energy strips electrons from the argon atoms, creating a mixture of free electrons and positively charged argon ions (Ar+). This energized, ionized gas is known as a plasma.

Step 4: The Collision and Ejection

The positively charged argon ions are powerfully accelerated by the electric field and slam into the negatively charged surface of the target material.

This impact is a pure momentum transfer. The argon ion strikes the target with enough force to dislodge, or "sputter," individual atoms from the target's surface.

Step 5: Deposition and Film Growth

The ejected target atoms travel in a vapor stream through the vacuum chamber. When they reach the cooler substrate, they condense on its surface.

Over time, these atoms build up layer by layer, forming a thin, dense, and highly uniform film with specific, desirable properties.

The Key Components of a Sputtering System

Understanding the function of each component clarifies how the process is so precisely controlled.

The Target (The Source Material)

This is a block or plate of the pure material you wish to deposit, such as titanium, aluminum, gold, or a specific alloy. The composition of the target directly determines the composition of the final film.

The Substrate (The Destination)

This is the object being coated. Substrates can range from silicon wafers and glass panels to plastic components and medical implants.

The Plasma (The Workforce)

The plasma provides the energetic ions that do the physical work of sputtering. The density and energy of the plasma are key variables used to control the rate of deposition.

The Power Supply & Electric Field (The Engine)

The power supply creates the voltage that both ignites the plasma and accelerates the ions toward the target. In many modern systems, magnets are also used behind the target (magnetron sputtering) to trap electrons, which drastically increases the efficiency of the plasma and allows for faster sputtering rates at lower pressures.

Understanding the Trade-offs and Considerations

Sputtering is a powerful technique, but it is not the right choice for every application. Understanding its limitations is key to using it effectively.

High Adhesion, Slower Speed

Sputtered atoms arrive at the substrate with significant kinetic energy, which helps them form a very dense and well-adhered film. However, the process is generally slower than other methods like thermal evaporation.

Line-of-Sight Deposition

The sputtered atoms travel in relatively straight lines from the target to the substrate. This can make it challenging to uniformly coat complex, three-dimensional shapes without sophisticated substrate rotation and manipulation.

Process Complexity and Cost

Sputtering requires a vacuum chamber, high-voltage power supplies, and precise gas flow control. The initial equipment cost and operational complexity are higher than simpler coating methods like electroplating or painting.

Making the Right Choice for Your Goal

The decision to use sputtering depends entirely on the required properties of the final film.

- If your primary focus is high-purity and uniform coatings: Sputtering offers exceptional, sub-nanometer control over film thickness and composition across large surface areas.

- If your primary focus is coating with complex alloys or compounds: Sputtering excels because it generally preserves the original stoichiometry of the target material in the deposited film.

- If your primary focus is coating heat-sensitive materials: Sputtering is a "cold" process that does not require melting the source material, making it ideal for delicate substrates like plastics or electronics.

Ultimately, choosing sputtering is a strategic decision to prioritize film quality, purity, and adhesion over deposition speed or initial cost.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Momentum transfer from ion bombardment in a plasma |

| Key Benefit | Dense, uniform, high-adhesion films |

| Ideal For | High-purity coatings, complex alloys, heat-sensitive substrates |

| Consideration | Slower deposition speed, line-of-sight limitation, higher equipment cost |

Need a high-purity, uniform metal coating for your project?

KINTEK specializes in lab equipment and consumables for advanced coating applications. Our expertise in sputtering targets and systems can help you achieve the precise, high-quality thin films your research or production demands.

Contact our experts today to discuss your specific requirements and discover the right sputtering solution for you.

Visual Guide

Related Products

People Also Ask

- How do you clean a sputter coater? Prevent Contamination for Flawless Thin Films

- How do high-energy mixing systems improve slurry-bed photocatalytic reactors? Maximize Your Catalyst Efficiency

- What are the routes of sintering? Choose the Best Method for Your Material

- How is plastic waste different from other types of waste? The Hidden Threat of Microplastics

- What are the environmental issues with diamond mining? Uncover the True Ecological and Human Cost

- What is a slow pyrolysis? A Guide to Maximizing Biochar Production from Biomass

- What is the difference between sputtering and Ebeam? Choose the Right Thin Film Deposition Method

- Why is an ultrasonic homogenizer used for LNMO samples? Ensure Accurate Particle Size Distribution Analysis