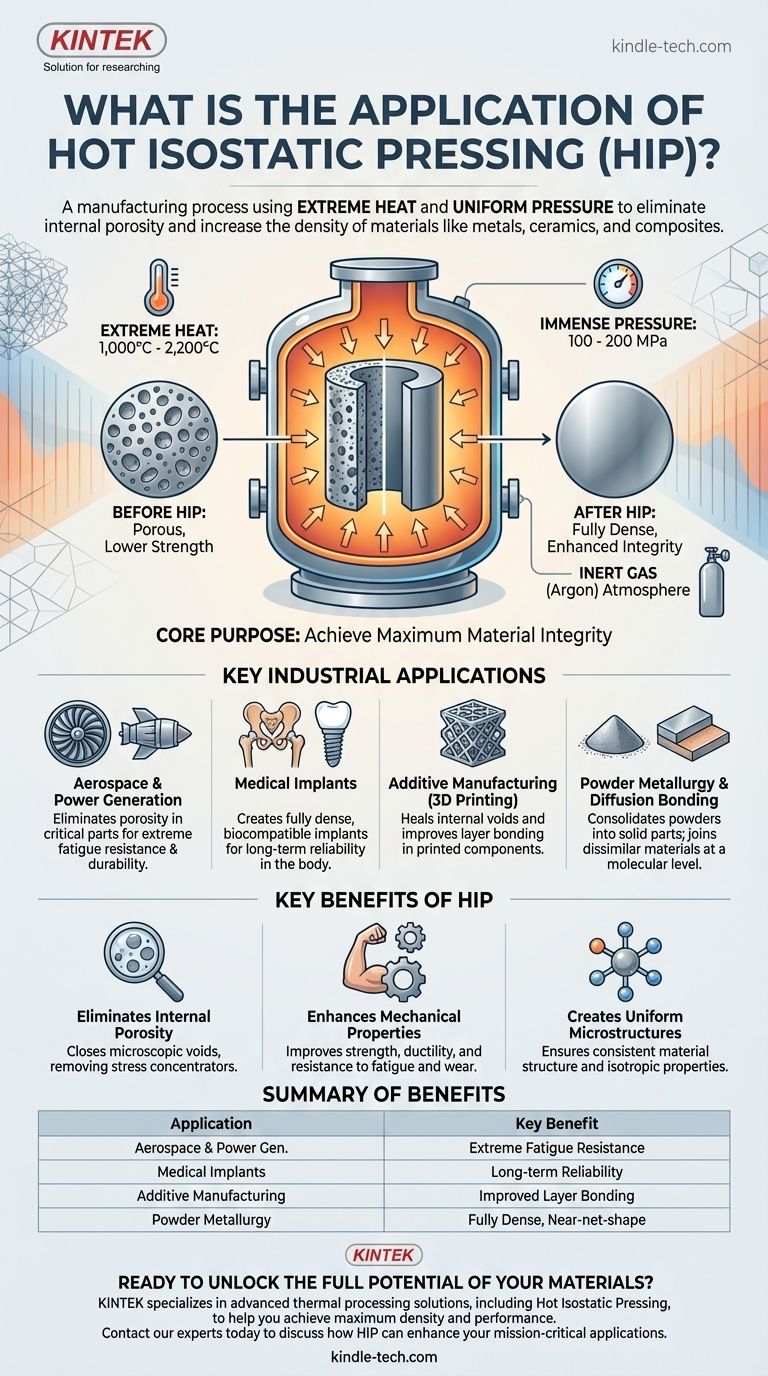

In short, Hot Isostatic Pressing (HIP) is a manufacturing process used to eliminate internal porosity and increase the density of materials like metals, ceramics, and composites. Its primary applications are in industries where component failure is not an option, such as creating parts for aerospace, medical implants, and power generation, as well as improving the quality of additively manufactured (3D printed) components.

The core purpose of Hot Isostatic Pressing is to achieve maximum material integrity. By subjecting parts to extreme heat and uniform pressure, it removes the microscopic internal voids that compromise strength, durability, and fatigue life, making it essential for high-performance and mission-critical applications.

What Problem Does Hot Isostatic Pressing Solve?

At its heart, HIP is a corrective and enhancing process. It targets the inherent flaws that can be introduced during casting, sintering, or 3D printing, transforming a standard part into a high-performance one.

Eliminating Internal Porosity

Most metal manufacturing processes, especially casting and 3D printing, can leave behind tiny internal voids or pores. These microscopic gaps act as stress concentrators and are the primary points where cracks can initiate and propagate, leading to component failure.

HIP physically closes and welds these internal voids shut by applying uniform pressure from all directions. This creates a fully dense, homogenous material.

Enhancing Mechanical Properties

By removing porosity, HIP dramatically improves a component's mechanical characteristics. The material becomes stronger, more ductile, and significantly more resistant to fatigue and wear.

This enhancement allows components to withstand more demanding operational environments and have a longer, more reliable service life.

Creating Uniform Microstructures

For processes like metal 3D printing, HIP helps resolve issues like poor layer adhesion and inconsistent material structure. The combination of heat and pressure encourages diffusion between material grains and layers, resulting in a uniform, isotropic microstructure.

Key Industrial Applications in Detail

The benefits of HIP make it indispensable across a range of high-stakes industries where material performance is paramount.

Aerospace & Power Generation

In these sectors, components like turbine blades, engine casings, and structural parts operate under extreme temperatures and mechanical stress. HIP is used to densify castings and additively manufactured parts, ensuring they possess the fatigue resistance and durability required to prevent catastrophic failure.

Medical & Biomedical Devices

Medical implants, such as artificial hips and dental fixtures, must be biocompatible and incredibly durable. HIP is applied to these devices to eliminate any internal voids that could become failure points over a lifetime of use inside the human body.

Additive Manufacturing (3D Printing)

HIP is a critical post-processing step for many metal 3D-printed parts. It heals the porosity inherent in the printing process, improves layer bonding, and relieves internal stresses, transforming a printed object into a functional, high-strength engineering component.

Powder Metallurgy & Diffusion Bonding

HIP is also a primary manufacturing method. It can consolidate metal or ceramic powders into a fully solid, near-net-shape part, a process known as Powder Metallurgy.

Additionally, it can be used for Diffusion Bonding, where the process joins two or more dissimilar materials together at a molecular level without the need for adhesives or fasteners.

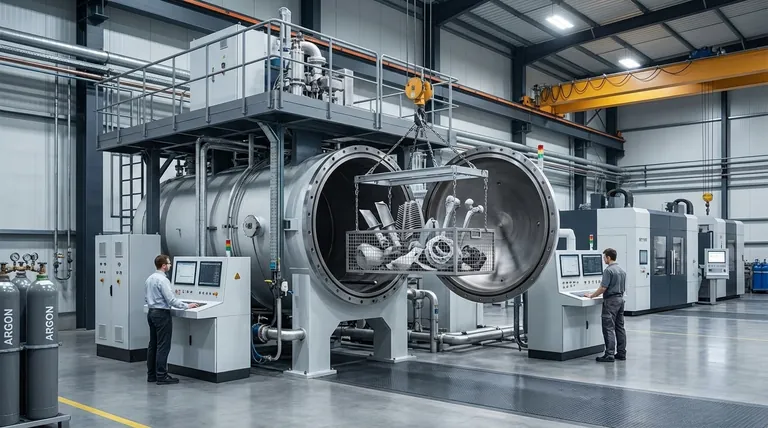

Understanding the Core Process

The effectiveness of HIP comes from its unique combination of process variables.

The Role of Heat and Pressure

A component is placed inside a high-pressure containment vessel. The vessel is heated to extremely high temperatures, often between 1,000°C and 2,200°C, which softens the material and makes it more malleable.

Simultaneously, the vessel is filled with a gas that applies immense, uniform pressure (typically 100-200 MPa) to the component's surface from every direction.

The Use of an Inert Gas

An inert gas, most commonly argon, is used as the pressure-transfer medium. This is critical because it prevents any chemical reaction or oxidation with the component material at elevated temperatures, ensuring the part's chemistry remains unaltered.

Making the Right Choice for Your Goal

Deciding whether to use HIP depends entirely on the performance requirements and failure risks associated with your component.

- If your primary focus is mission-critical reliability: HIP is an essential step for components in aerospace, energy, or medical applications where failure could have severe consequences.

- If your primary focus is optimizing additively manufactured parts: Consider HIP a necessary post-processing stage to transform 3D-printed metal objects into true engineering-grade components.

- If your primary focus is creating solid parts from powders or bonding unique materials: HIP is a powerful primary manufacturing method for producing fully dense components and complex multi-material assemblies.

Ultimately, hot isostatic pressing serves as a powerful tool to unlock the full theoretical potential of a material.

Summary Table:

| Application | Key Benefit |

|---|---|

| Aerospace & Power Generation | Eliminates porosity in turbine blades and engine parts for extreme fatigue resistance. |

| Medical Implants | Creates fully dense, biocompatible implants for long-term reliability in the body. |

| Additive Manufacturing (3D Printing) | Heals internal voids and improves layer bonding in metal 3D-printed components. |

| Powder Metallurgy | Consolidates metal/ceramic powders into fully solid, near-net-shape parts. |

Ready to unlock the full potential of your materials?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing, to help you achieve maximum density and performance in your metal, ceramic, and 3D-printed components. Whether you're in aerospace, medical, or additive manufacturing, our expertise ensures your parts meet the highest standards of reliability and strength.

Contact our experts today to discuss how HIP can enhance your mission-critical applications.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What role does a high-purity graphite mold play in the hot pressing sintering of Cr50Cu50 alloys? Achieve High Density

- Why is it essential to maintain a high vacuum state during hot press sintering? Optimize SiCp/2024Al Quality

- How does HIP equipment improve Zr-1Mo alloy ingots? Achieving Density and Magnetic Consistency

- What role does a graphite mold play in the Hot Pressing (HP) sintering process of LTPO? Master High-Density Sintering

- What is field assisted sintering? Achieve Rapid, High-Performance Material Densification

- How does a high vacuum environment contribute to the hot pressing of Ruthenium? Enhance Purity and Density

- What is the time for spark plasma sintering? Achieve Full Densification in Minutes

- How is a K-type thermocouple utilized during the hot pressing process of metal composites for precise thermal control?