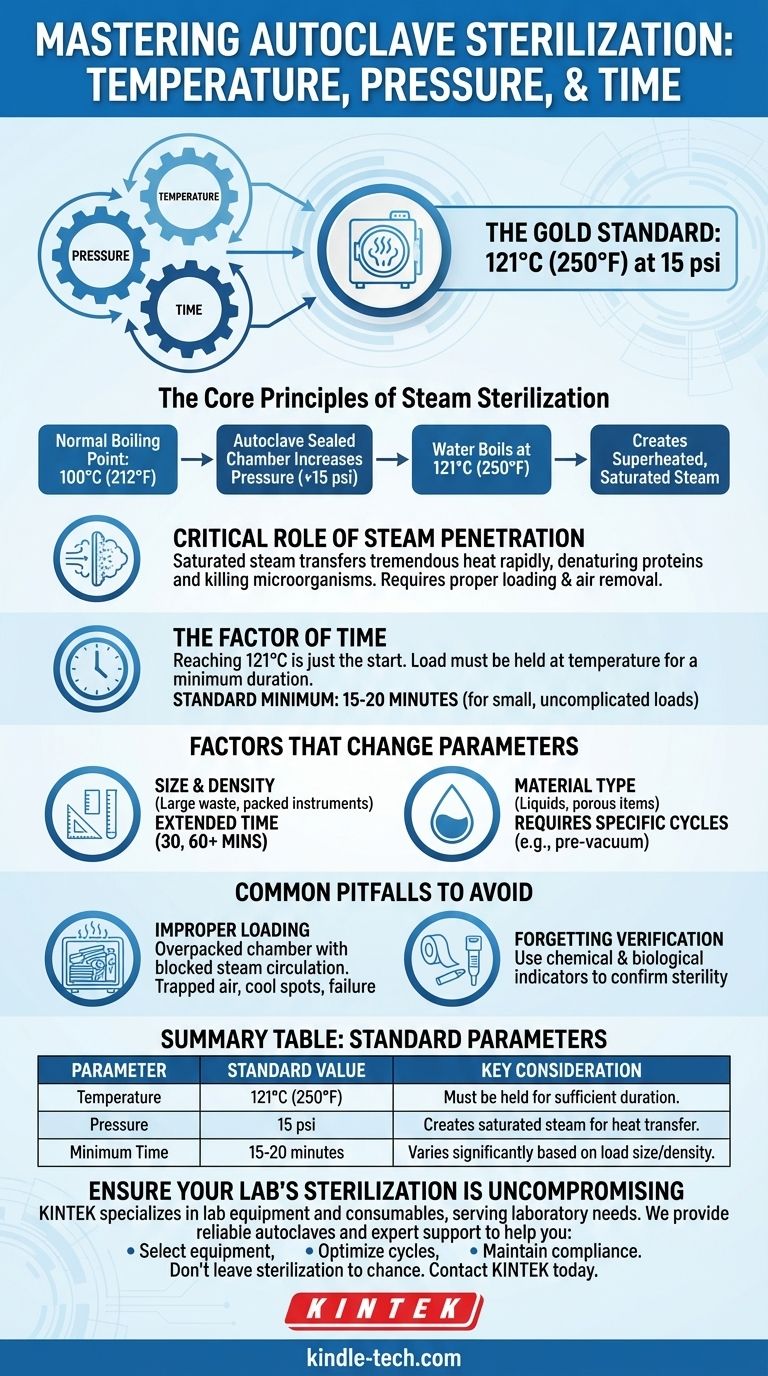

The standard temperature for autoclave sterilization is 121°C (250°F). This temperature is achieved by using saturated steam under a pressure of approximately 15 pounds per square inch (psi). However, achieving this temperature is only one part of the equation; the duration of the cycle is equally critical for ensuring complete sterilization.

Effective sterilization is not determined by temperature alone, but by the precise relationship between temperature, pressurized steam, and time. Understanding how these three elements work together is the key to ensuring your materials are truly sterile.

The Core Principles of Steam Sterilization

An autoclave doesn't just heat items; it uses pressurized steam to rapidly and efficiently kill all forms of microbial life, including resilient bacterial spores. This process relies on a specific set of physical principles.

Why Temperature and Pressure are Linked

The core function of an autoclave is to increase the boiling point of water. At normal atmospheric pressure, water boils at 100°C (212°F), which is not hot enough to reliably kill all microorganisms.

By increasing the pressure inside the sealed chamber to 15 psi above atmospheric pressure, the autoclave forces water to boil at 121°C. This creates superheated, saturated steam that is far more effective at sterilization than dry heat.

The Critical Role of Steam Penetration

Saturated steam is the actual sterilizing agent. It carries a tremendous amount of thermal energy that it transfers to the items in the load upon contact.

This rapid heat transfer denatures the essential proteins and enzymes within microorganisms, killing them quickly and effectively. This is why proper loading and air removal are critical for ensuring steam can contact every surface.

The Factor of Time

Reaching 121°C is the starting point, not the end. The load must be held at this sterilizing temperature for a minimum duration to ensure a complete kill.

The standard minimum time is 15 to 20 minutes, but this is only for small, uncomplicated loads. The actual time required depends entirely on what you are sterilizing.

Factors That Change Sterilization Parameters

A common mistake is assuming the "121°C for 15 minutes" rule is universal. The size, density, and type of the load being sterilized can dramatically alter the required cycle time.

Size and Density of the Load

A large bag of waste or a tightly packed set of instruments will take much longer for steam to penetrate than a few small glass beakers.

For larger or denser loads, the cycle time must be extended, sometimes to 30, 60 minutes, or even longer, to ensure the items in the very center of the load reach 121°C and remain there for the full contact time.

Type of Material Being Sterilized

Different materials require different considerations. A large flask of liquid media will take significantly longer to reach 121°C at its core than the surface of a metal instrument.

Similarly, sterilizing porous materials or wrapped surgical kits requires cycles that are designed to first remove air and then allow for deep steam penetration.

Common Pitfalls to Avoid

Achieving a successful sterilization cycle requires more than just pressing a button. Several common errors can lead to a failed cycle, even if the machine appears to run correctly.

Improper Loading

Overpacking the autoclave chamber is a primary cause of sterilization failure. If items are packed too tightly, it creates barriers that block steam circulation.

This leads to trapped air pockets and cool spots where items are not fully sterilized, despite the autoclave's sensors reading the correct temperature and pressure.

Forgetting Cycle Verification

Never assume a cycle was successful just because it finished. Chemical indicators (like autoclave tape) should be used on every load to show that sterilizing temperatures were reached.

For critical applications, such as in healthcare or pharmaceuticals, biological indicators containing heat-resistant spores are used periodically to definitively prove that the autoclave is capable of killing the hardiest microorganisms.

Making the Right Choice for Your Goal

To ensure effective sterilization, you must match your cycle parameters to the specific load.

- If your primary focus is sterilizing standard lab glassware or unwrapped metal instruments: The baseline of 121°C at 15 psi for 15-20 minutes is a reliable and efficient starting point.

- If your primary focus is sterilizing liquids, media, or dense waste: You must increase the cycle time significantly, often to 30 minutes or more, to account for slower heat penetration.

- If your primary focus is sterilizing wrapped kits or porous materials: Use a cycle with a pre-vacuum phase if available, and extend the time to ensure steam fully penetrates all layers.

Mastering the interplay of temperature, pressure, and time for your specific application is the only way to guarantee truly sterile results.

Summary Table:

| Parameter | Standard Value | Key Consideration |

|---|---|---|

| Temperature | 121°C (250°F) | Must be held for a sufficient duration. |

| Pressure | 15 psi | Creates saturated steam for effective heat transfer. |

| Minimum Time | 15-20 minutes | Varies significantly based on load size and density. |

Ensure Your Lab's Sterilization is Uncompromising

Achieving true sterility requires more than just the right temperature. It demands an understanding of how time, pressure, and steam penetration work together for your specific materials.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. We provide reliable autoclaves and expert support to help you:

- Select the right equipment for your sterilization requirements (liquids, waste, instruments).

- Optimize cycle parameters to ensure complete sterility every time.

- Maintain compliance with industry standards through proper validation.

Don't leave your sterilization to chance. Contact KINTEK today to discuss your lab's needs and ensure your processes are safe, effective, and reliable.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- How many types of autoclave are there? The Definitive Guide to Gravity vs. Prevacuum

- What are the tips for using an autoclave? Ensure Effective Sterilization and Safety

- What role does a high-pressure hydrothermal autoclave play in 3D-GO synthesis? Optimize Your Graphene Composites

- What are the 3 stages of autoclave sterilization? Master the Purge, Exposure & Exhaust Phases

- What is the proper pressure and temperature for sterilizing instruments? Achieve True Sterility with the Right Parameters

- What is the most common sterilization technique used in labs? Mastering the Autoclave for Unmatched Safety

- What is the equivalent of an autoclave? Find the Right Sterilization Method for Your Needs

- How long should an autoclave last? Maximize Your Investment with Proper Care